Rear tilting mechanism moving assembly for automobile sunroof

A technology of mechanism movement and automobile sunroof, applied in the directions of vehicle parts, transportation and packaging, roof, etc., can solve the problems of difficult processing and production, many components, easy to fail, etc., to shorten the production and assembly cycle of the sunroof, and simplify the movement of the sunroof. The effect of stable and reliable mechanism and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

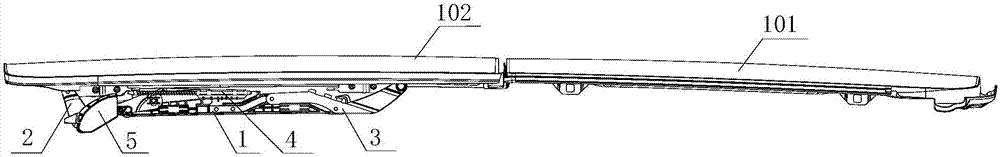

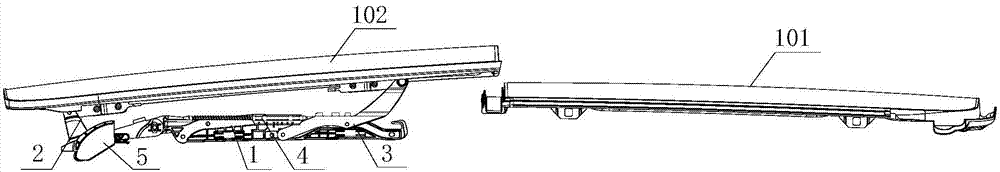

[0023] Such as Figure 1-2 As shown, a car sunroof rear lifting mechanism motion assembly of the present invention includes two sets of slide rails 6, a rear lifting mechanism 3, a driving slider 1 and a flexible shaft 4, and the rear glass 101 is fixedly installed on the roof of the car At the rear of the frame, the front glass 102 is installed on the front of the car roof sunroof frame. After the rear lifting mechanism 3 drives the front glass 102 to lift, the front lifting mechanism 2 drives the front glass 102 to lift. At this time The front glass 102 is lifted, and after lifting, it can move toward the rear glass 101 along the slide rail 6 to complete the opening or closing of the sunroof.

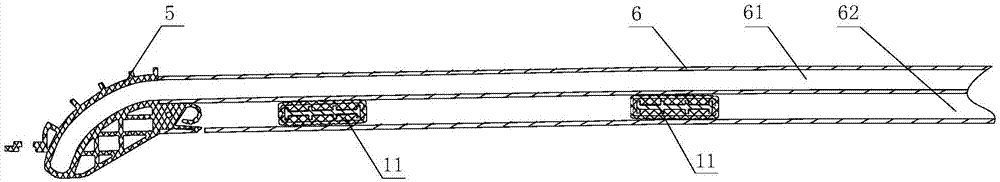

[0024] Two sets of slide rails 6 are respectively fixedly installed on both sides of the long side of the skylight frame, each set of slide rails 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com