Bearing spring outline dimension detection device and method

A technology of external dimensions and suspension springs, which is applied in the field of detection devices for the external dimensions of suspension springs, can solve problems such as potential safety hazards, reduced service life of vehicles, mutual wear of parts, etc., to achieve the effect of eliminating potential safety hazards and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

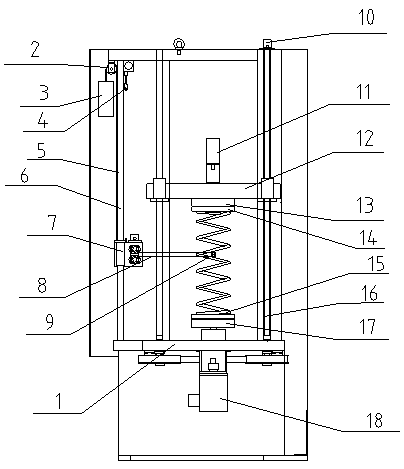

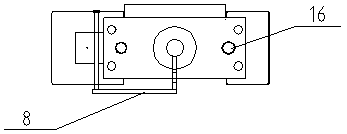

[0038] Such as figure 1 with 2 As shown, the suspension spring external dimension detection device provided in this embodiment includes a workbench 1 and a control system. The workbench 1 is provided with a spring compression mechanism, a spring height measurement sensor 10 and spring parameter measurement components. The spring compression mechanism compresses the spring, the spring height measuring sensor 10 detects the spring height, and the spring parameter measuring part measures the outer diameter and pitch of the spring. The spring height measuring sensor 10 may be a displacement sensor. The control system is used to control the spring compression mechanism to compress the spring and receive the measurement data from the spring height measurement sensor 10. When the spring is compressed to a preset height, the control system measures the outer diameter and pitch of the spring through the spring parameter measurement component. It should be noted that in this embodimen...

Embodiment 2

[0047] On the basis of Embodiment 1, this embodiment provides a method for detecting the outer dimension of the suspension spring based on the above detection device, which specifically includes the following steps:

[0048] S1: place the spring between the upper torsion disk 14 and the lower torsion disk 15;

[0049] S2: the control system controls the lifting motor 18 to drive the middle crossbeam 12 down to compress the spring; at the same time, the control system receives the measurement data from the spring height measuring sensor 10;

[0050] S3: When the spring is compressed to the first preset height, the control system controls the lifting motor 18 to stop working, and the middle beam 12 does not move;

[0051] S4: connecting the radial measuring rod 8 with the spring;

[0052] S5: the control system controls the rotating motor 11 to drive the upper torsion plate 14 to rotate to rotate the spring;

[0053] S6: The spring drives the radial measuring rod 8 to move, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com