Power supply terminal and charging gun head

A power terminal and terminal technology, applied in circuits, electrical components, contact parts, etc., can solve problems such as difficulty in two-hand operation, reduce the insertion and extraction force of charging guns, etc., and achieve the effect of reducing labor intensity and reducing insertion and extraction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

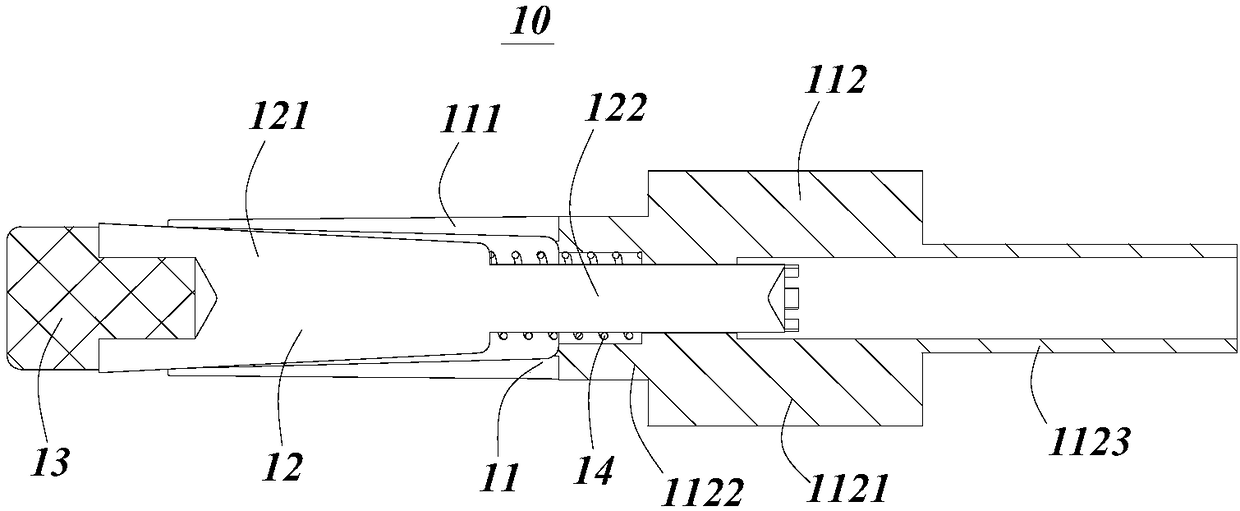

[0040] ginseng figure 1 As shown, the power terminal 10 in this embodiment includes a hollow terminal expansion tube 11, a terminal core rod 12 axially installed in the terminal expansion tube, an insulating head 13 fixedly installed on the end of the terminal core rod, and a terminal core rod fixed to the terminal. The elastic member 14 between the core rod and the terminal expansion tube.

[0041] Wherein, the terminal mandrel 12 includes an inserting portion 122 and a clamping portion 121, the terminal expansion tube 11 includes a mounting portion 112 and an expansion joint portion 111, the clamping portion 121 of the terminal core rod 12 and the expansion joint portion 111 of the terminal expansion tube 11 For coordinated installation, the insertion portion 122 of the terminal core rod 12 is fitted with the installation portion 112 of the terminal expansion tube 11 .

[0042] Specifically, in this embodiment, the cross-section of the clamping portion 121 of the terminal m...

Embodiment 2

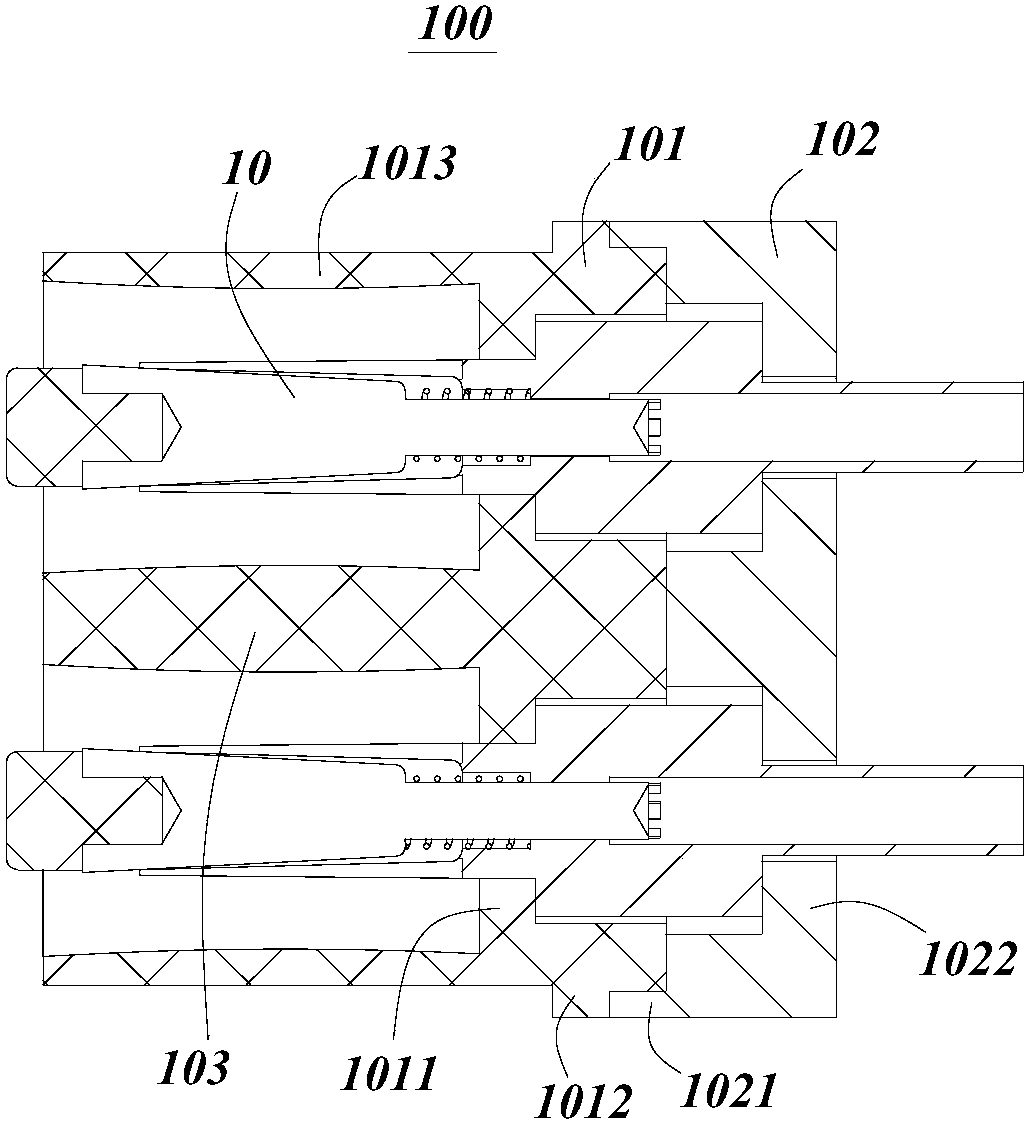

[0051] ginseng figure 2 As shown, the present embodiment discloses a charging gun head 100, which includes a plurality of power terminals 10, and a cover fixedly installed on the outside of the power terminals.

[0052] The power terminal 10 includes a hollow terminal expansion tube 11, a terminal core rod 12 axially installed in the terminal expansion tube, an insulating head 13 fixedly installed at the end of the terminal core rod, and a terminal core rod fixed between the terminal core rod and the terminal expansion tube. The specific structure of the elastic member 14 and the power terminal 10 is exactly the same as that in Embodiment 1, and will not be repeated here.

[0053] In this embodiment, the cover body includes a first cover body 101 and a second cover body 102 which are separated from each other. The first cover body 101 and the second cover body 102 are respectively provided with a number of limiting parts, through which the first cover body 101 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com