A glass cutting device

A glass cutting and cutting mechanism technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting cutting quality, complicated cutting process, and easy deviation of manual positioning, etc., to achieve the best cutting effect, fast and The effect of accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

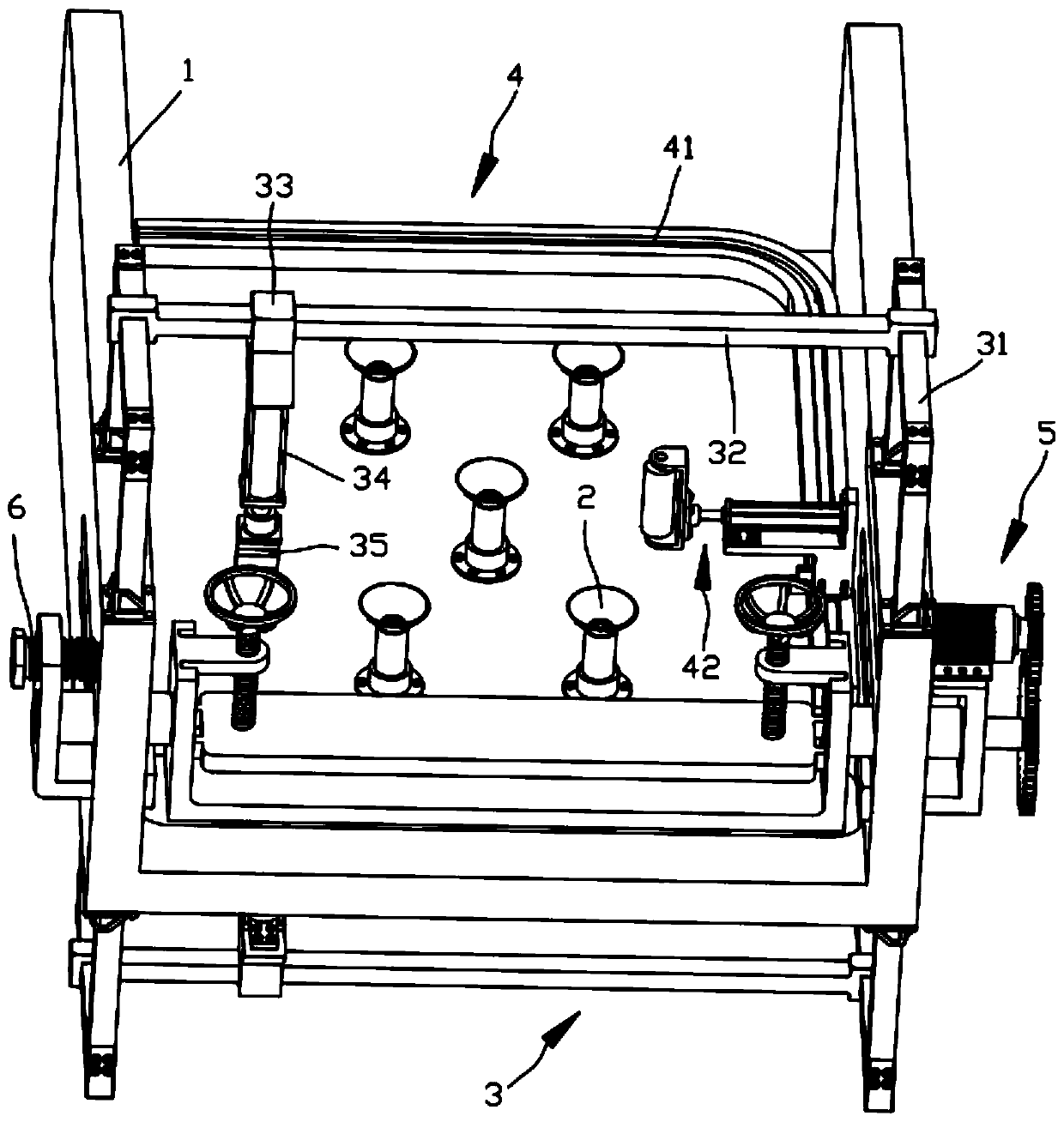

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution:

[0025] A glass cutting device, comprising a frame 1, a suction cup 2, a cutting mechanism 3, a calibration mechanism 4, an edge breaking mechanism 5 and fastening bolts 6, wherein:

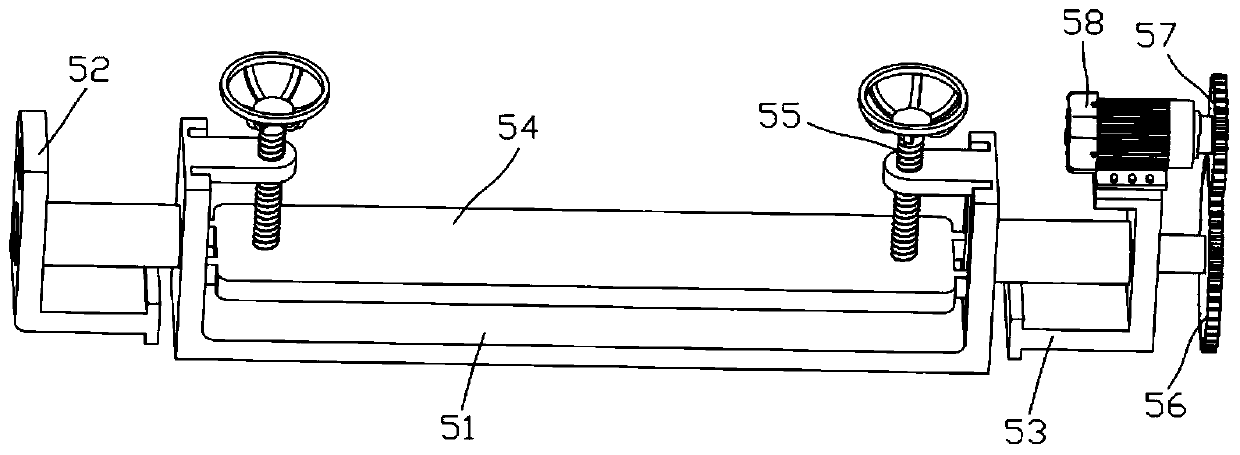

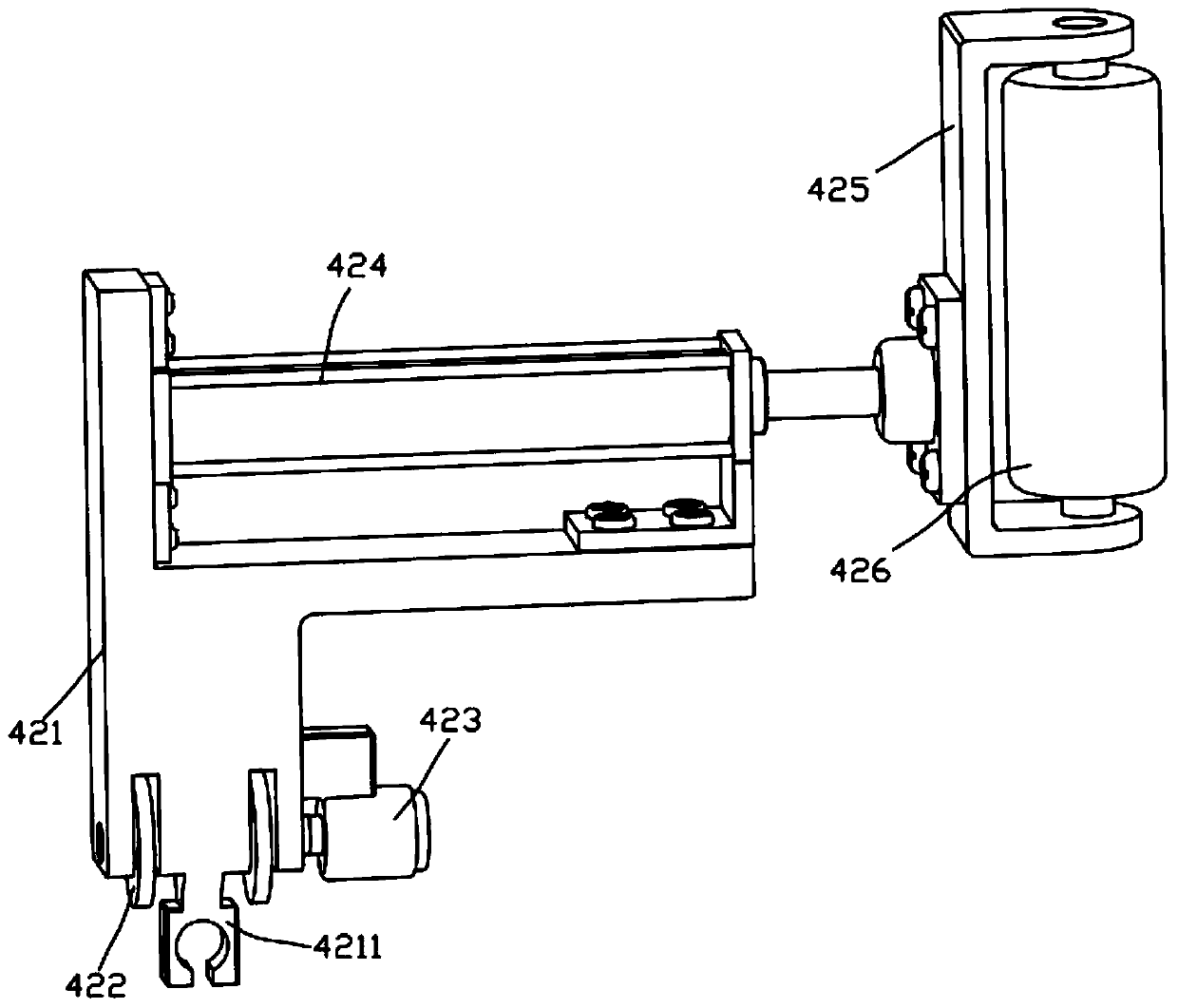

[0026] A number of suction cups 2 are fixedly installed on the frame 1, and the suction cups 2 are evenly distributed, wherein the suction cups 2 are externally connected to the air pressure source, and two cutting mechanisms 3 are installed oppositely at the upper and lower ends of the frame 1. The cutting mechanism 3 includes pneumatic guide rails I31, pneumatic guide rails Ⅱ32, pneumatic slider 33, cylinder 34 and cutter 35, two pneumatic guide rails Ⅰ31 are respectively fixedly installed on the two sides of the frame 1 through supporting legs, and the two ends of the pneumatic guide rail Ⅱ32 are respectively movably installed on the two pneumatic guide rails Ⅰ31 At this time, the pneumatic guide rail II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com