Floor support base plate and prepared technology and module type laying assembly

A technology for supporting the bottom plate and preparation process, applied in the direction of floor, building, building structure, etc., can solve the problems of unstable installation, long disassembly and assembly time, etc., and achieve the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

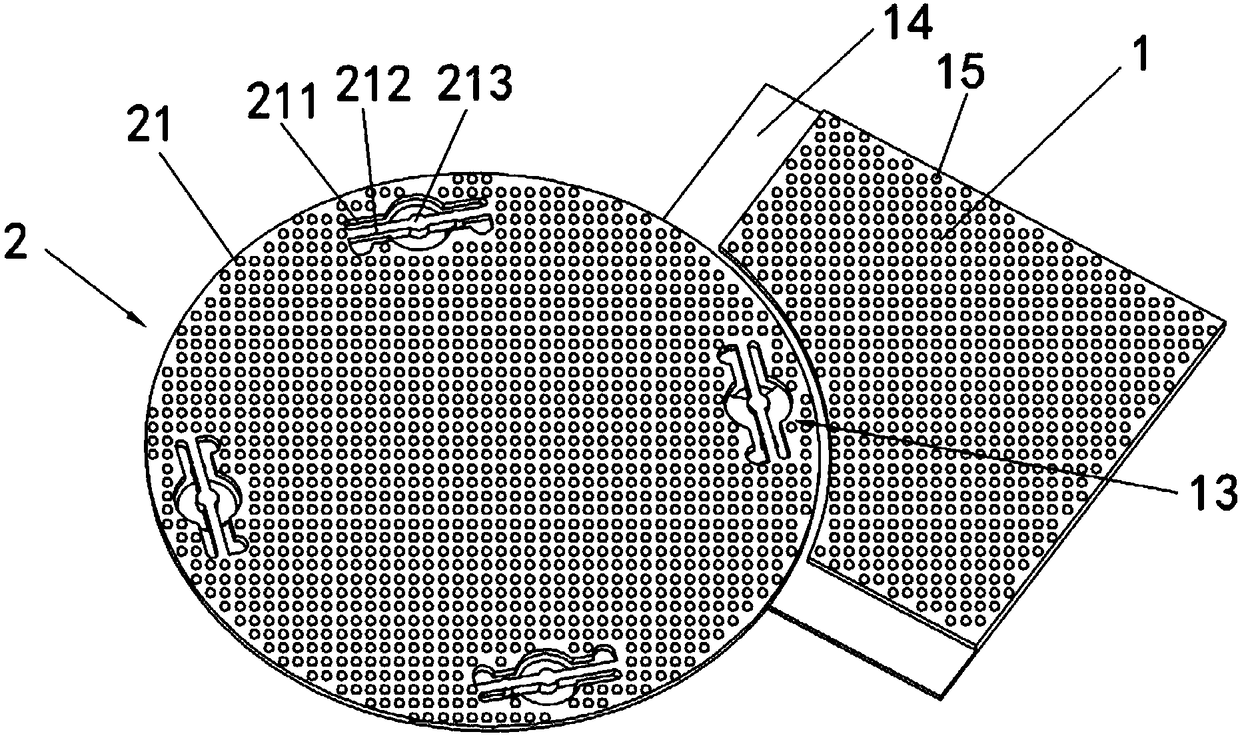

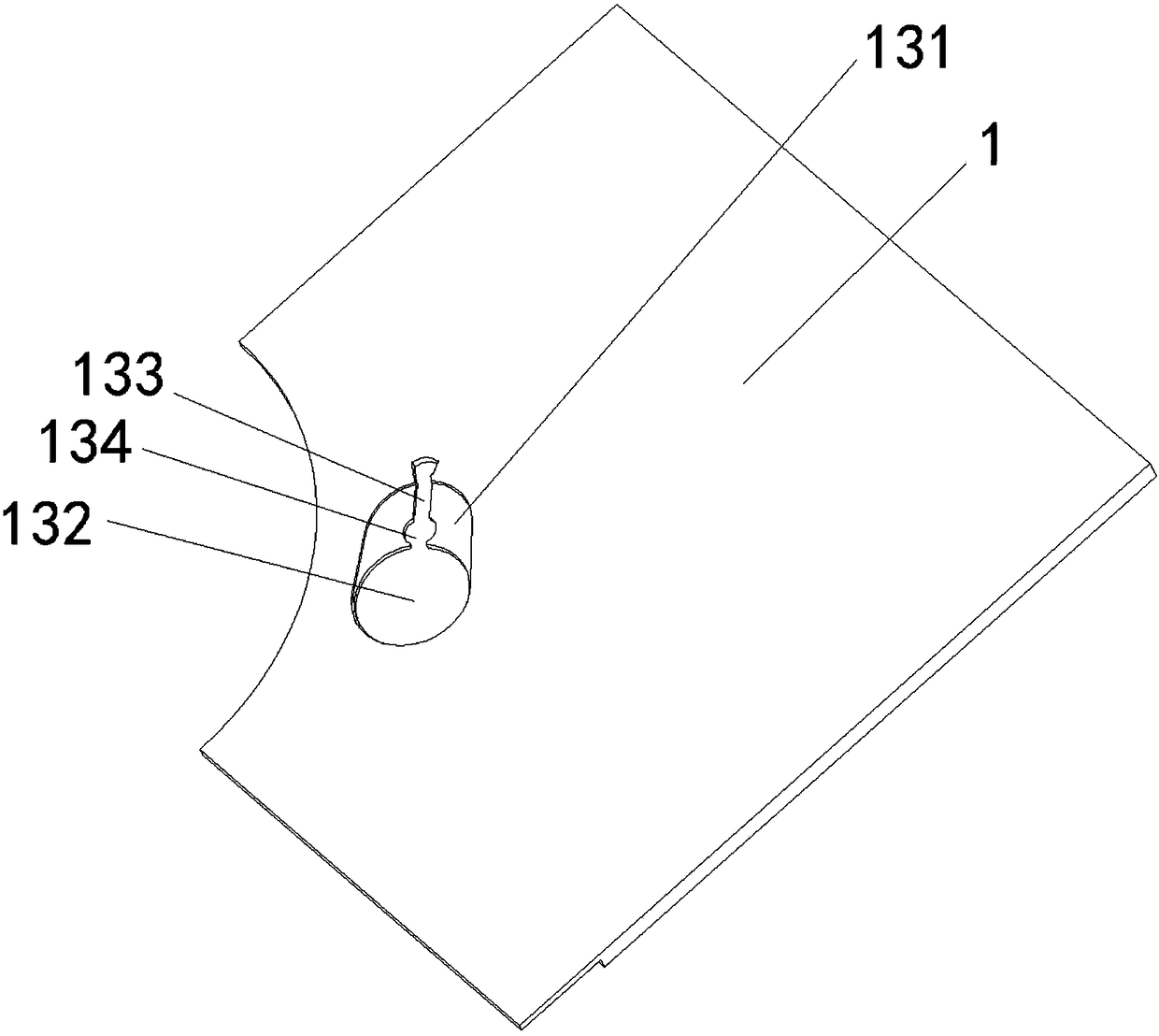

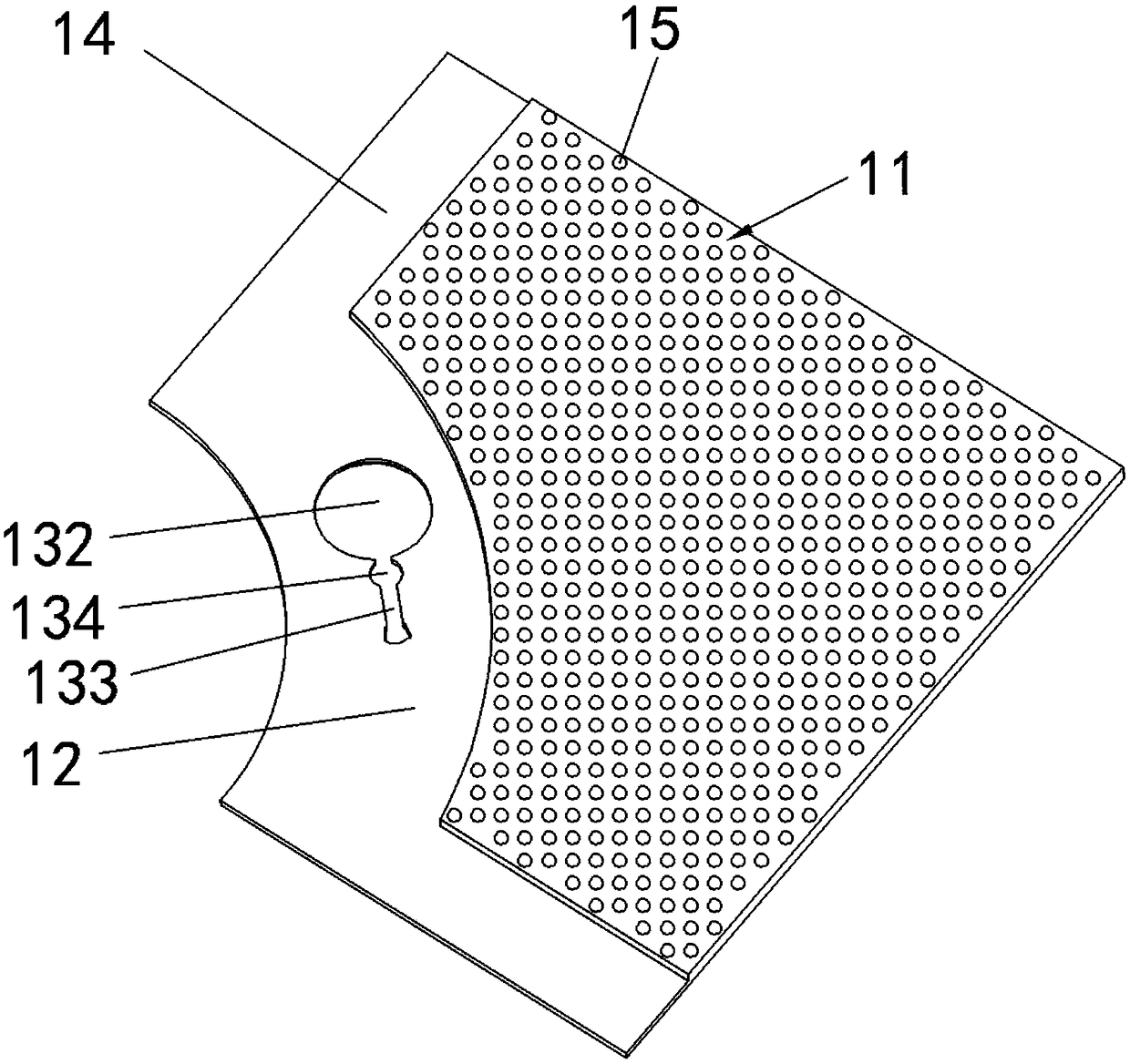

[0041] The following is attached Figure 1-5 The present invention is described in further detail.

[0042] A floor support base such as Figure 1-4 As shown, it includes a rectangular plate-shaped floor body 1 and a circular plate-shaped lock plate 2, and the upper surface of the floor body 1 and the lock plate 2 are provided with a plurality of mushroom-shaped protrusions 15 in a rectangular array. Mushroom-shaped protrusions 15 are provided to facilitate fast lamination when the surface floor is laid after the floor body 1 is spliced. The diameter of the disc 21 is larger than that of the lower disc 22, and the lower surface of the upper disc 21 is provided with four limiting discs 23 in an array along its circumferential direction. Matching 1 / 4 round matching groove 11, the end of the lock plate 2 is located at the matching groove 11 position and extends with a 1 / 4 round connecting ring plate 12 that cooperates with the lower disc 22, the thickness of the connecting ring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com