A visualization method and device for measuring the accuracy of microwave reflecting surfaces

A technology of microwave reflection and precision measurement, which is applied in the antenna radiation pattern and other directions, can solve the problems of small protrusions that cannot be measured in the normal direction, judgment failure, and low efficiency, and achieve the effects of reducing human subjective assumptions, improving molds, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the invention are given below in conjunction with the accompanying drawings to describe the technical solutions of the present invention in detail. Here, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that the preferred implementation examples described here are only used to illustrate and explain the present invention, and are not used to limit or limit the present invention.

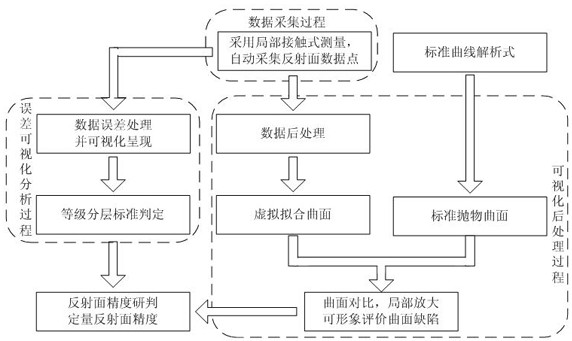

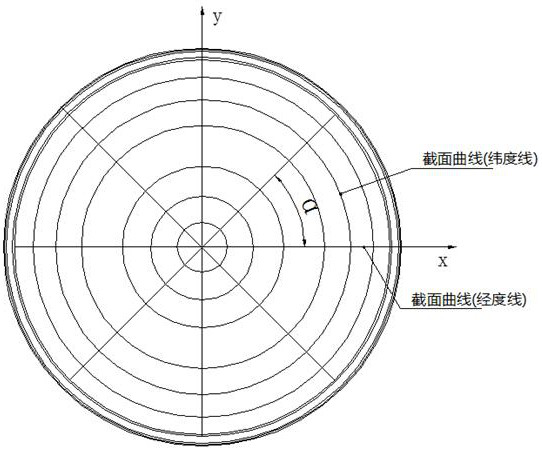

[0036] A visualization method for measuring the accuracy of microwave reflective surfaces:

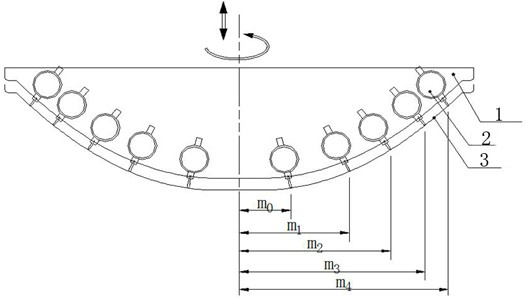

[0037] Step 1. Contact multiple measuring instruments with local points on the measured microwave reflective surface at normal angles, and calculate the actual measured normal parameters with the measured data of the measured points

[0038] In current engineering, it is usually used to measure the accuracy of the reflective surface by using the combination of the curve plate and the feeler gauge. This meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com