Device and method for spinning cylindrical titanium alloy part

A cylindrical, titanium alloy technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., to achieve the effect of improving the level of strength, grain size, product organization and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

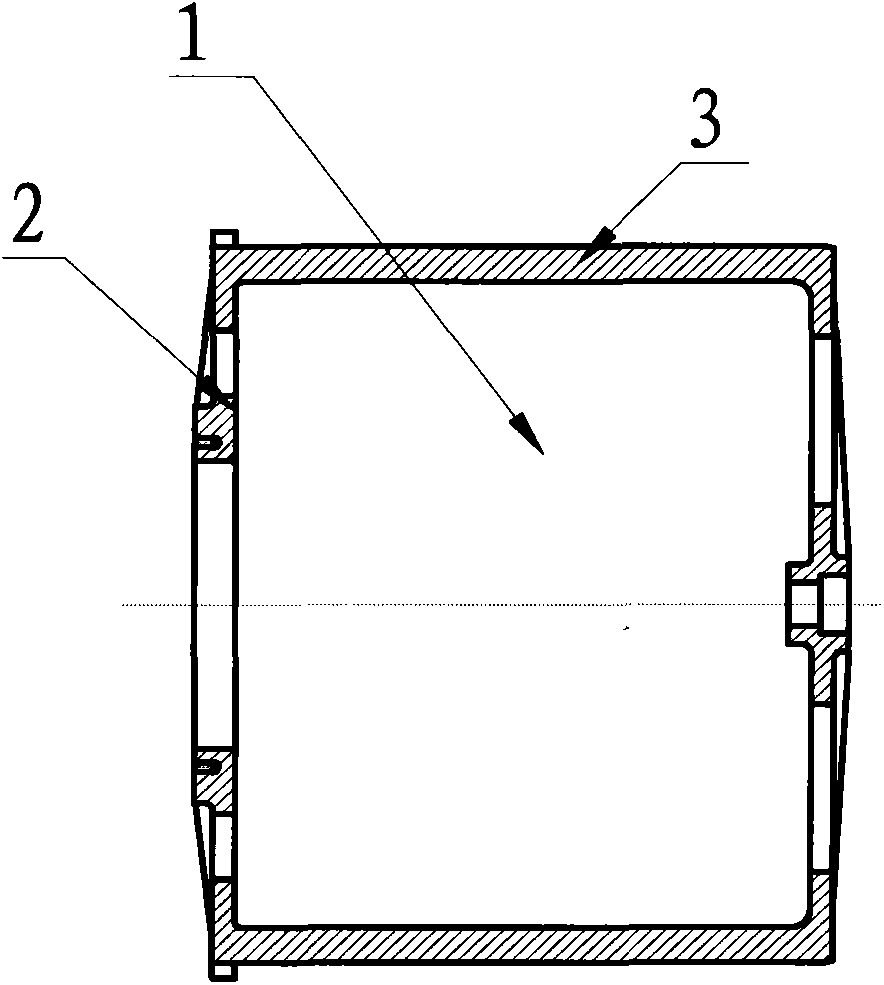

[0030] Example of implementation of the present invention: the inner diameter of the blank of the titanium alloy cylindrical spinning part 10 is 1500-2500mm, the wall thickness of the blank is 45mm, and the effective length is 700mm.

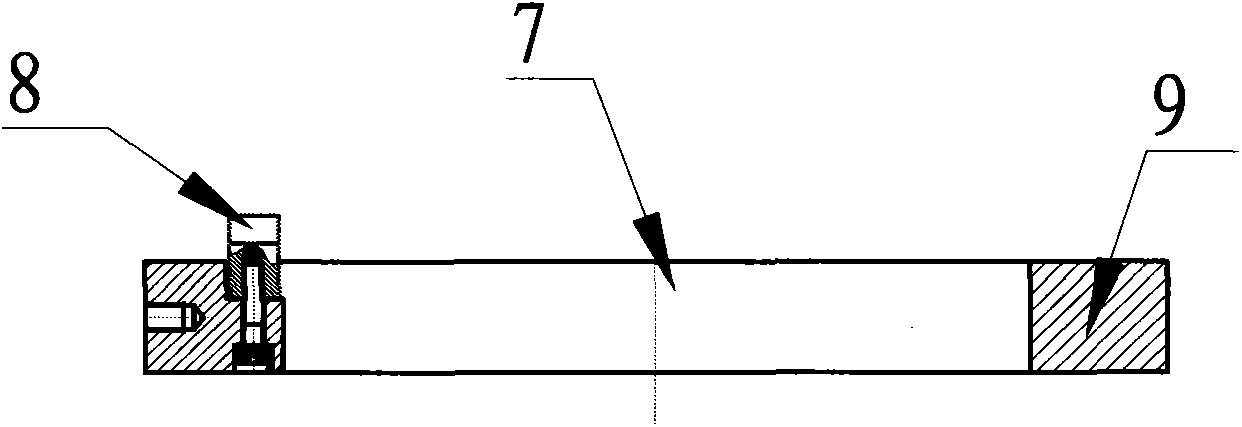

[0031] as attached Figure 1-4 As shown, the heated titanium alloy cylindrical spinning part 10 is installed in the spinning die 1 , and the cylindrical spinning part 10 is attached to the toothed disc device 7 .

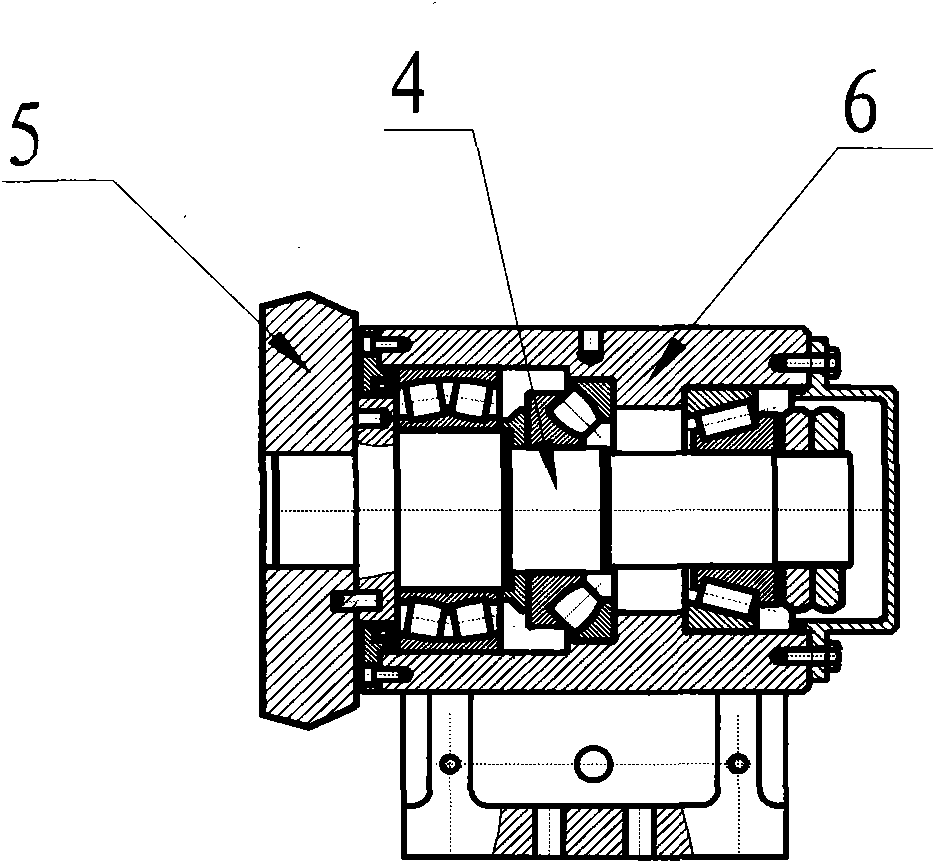

[0032] The spinning die 1 is directly connected to the spindle of the spinning machine tool. The spinning die 1 performs a rotary motion in the spinning process, which is the main movement in the spinning process. The spinning wheel device 4 is connected with the sliding seat of the spinning machine tool. Feed movement during processing. During spinning, the rotation of the spindle of the spinning machine tool drives the spinning mold 1 to rotate, and the spinning mold 1 drives the toothed disc device 7 and the cylindrical spinning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com