Assembly type organic glass stair concrete pouring mold

A technology of plexiglass and pouring molds, which is used in construction, building structure, formwork/template/work frame, etc., can solve the problems of inconvenient pouring and hoisting, heavy steel plate weight, tedious assembly molds, etc. The effect of reducing production costs and improving pouring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

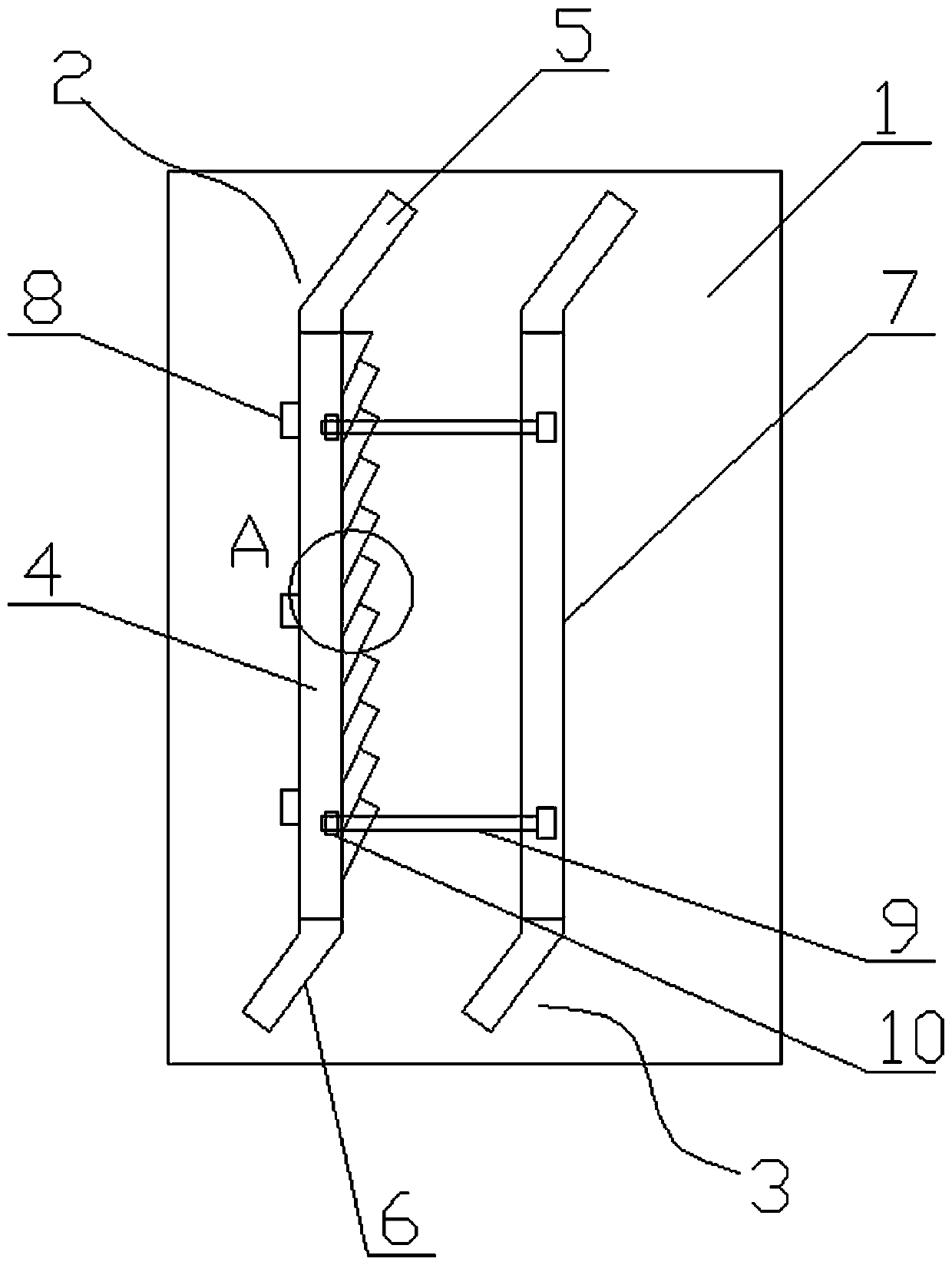

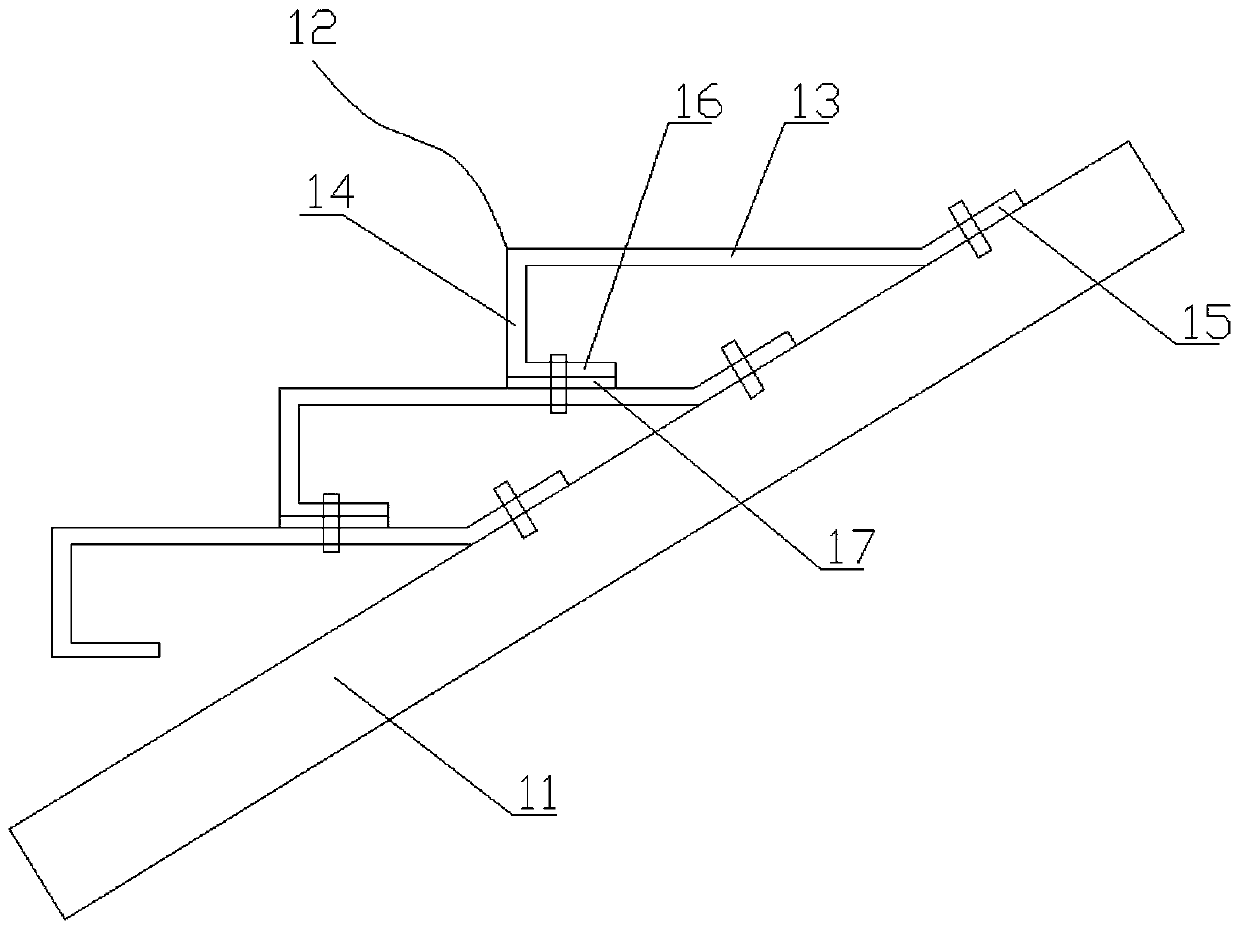

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

[0014] figure 1 , 2 Shown: a plexiglass assembled staircase concrete pouring mold includes a base 1, a ladder-shaped fixed formwork 2, a flat-shaped movable formwork 3, a linear ladder-shaped fixed formwork 4, a front-end formwork 5, a rear-end formwork 6, and a parallel-shaped movable formwork 7 , frame column 8, template locking screw 9, locking bayonet 10, beam body 11, right-angle bending plate 12, inclined fixing plate 15, right-angle fixing plate 16, backing plate 17, and step sealing plate and moving sealing plate for packaging Plates, bottom seals, top seals and both end seals, step seals, movable seals, bottom seals, top seals and both ends seals are necessary structures in traditional molds, and this invention uses acrylic plates instead Traditional wood or steel boards, acrylic boards are pre-polymerized and built-in or hole-bonded and built-in correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com