Support-integrated reflector

A technology of reflectors and support plates, applied in installation, optics, instruments, etc., can solve problems such as separate processing and assembly, achieve the effects of reducing weight and number of parts, increasing resonance frequency, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

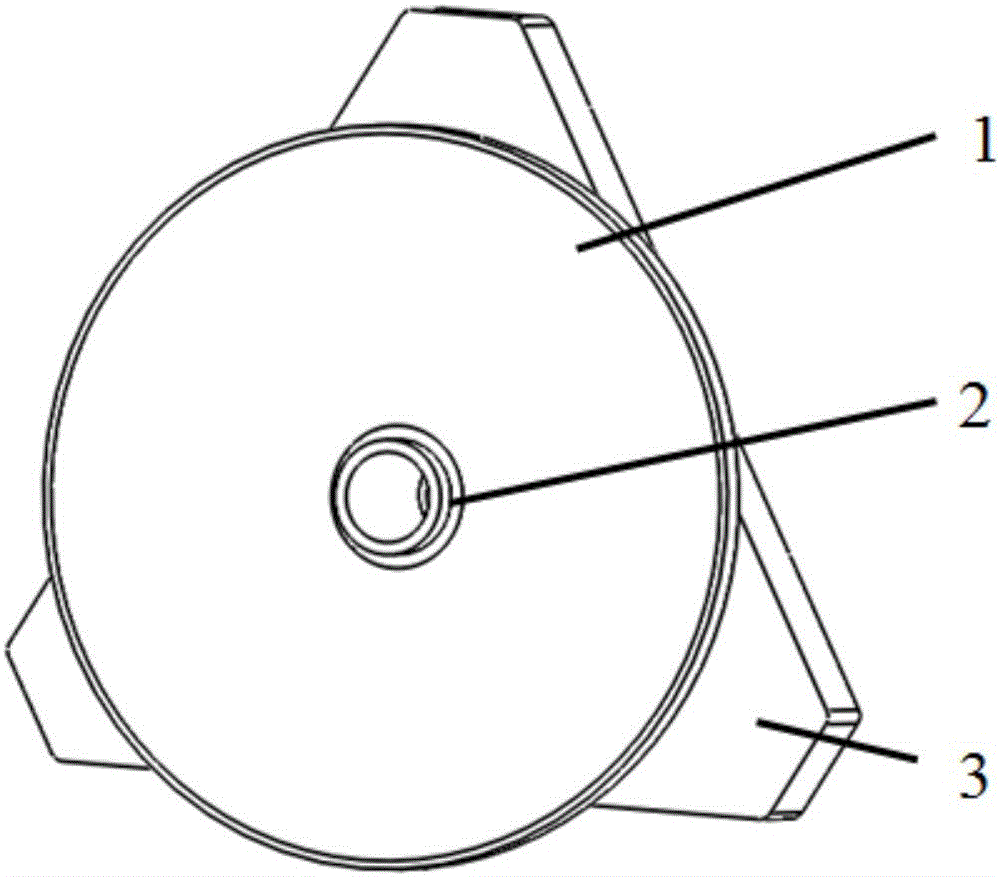

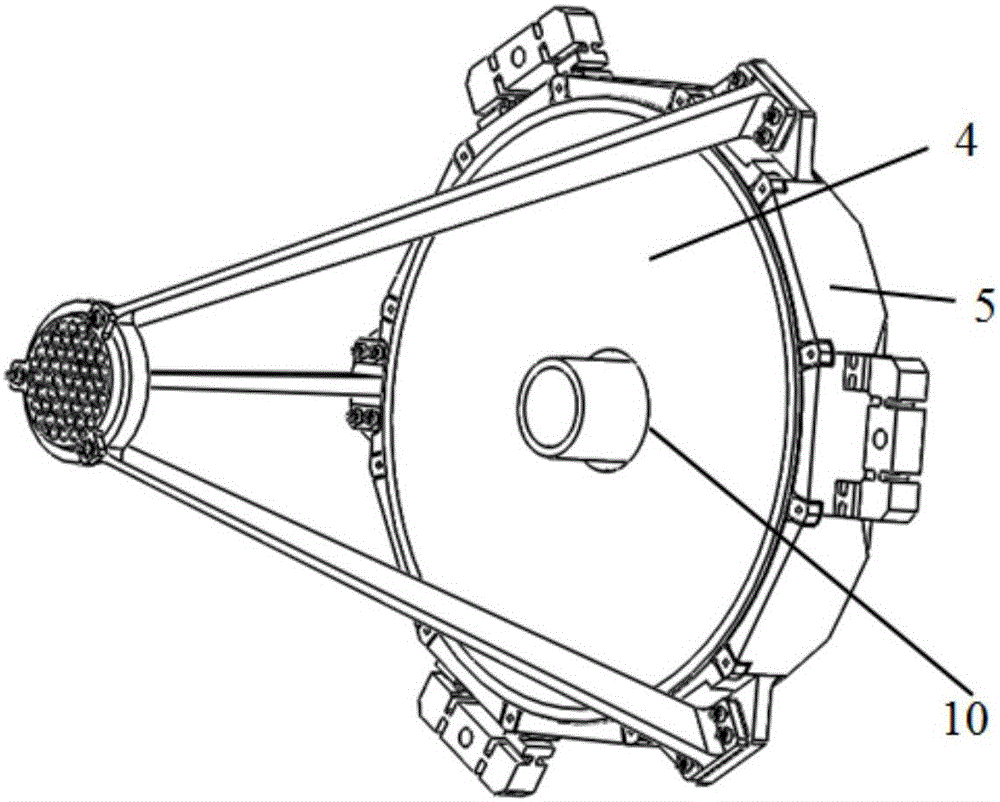

[0034] see Figure 2 to Figure 4 , the preferred embodiment of the reflector provided by the present invention is integrally formed by metal materials, and its structure mainly includes a reflector panel 4, a support plate 5 and a back plate 6; the support plate 5 is located between the reflector panel 4 and the back plate 6 between. A central hole 10 for setting a correcting mirror is arranged in the center of the reflecting mirror along the axial direction.

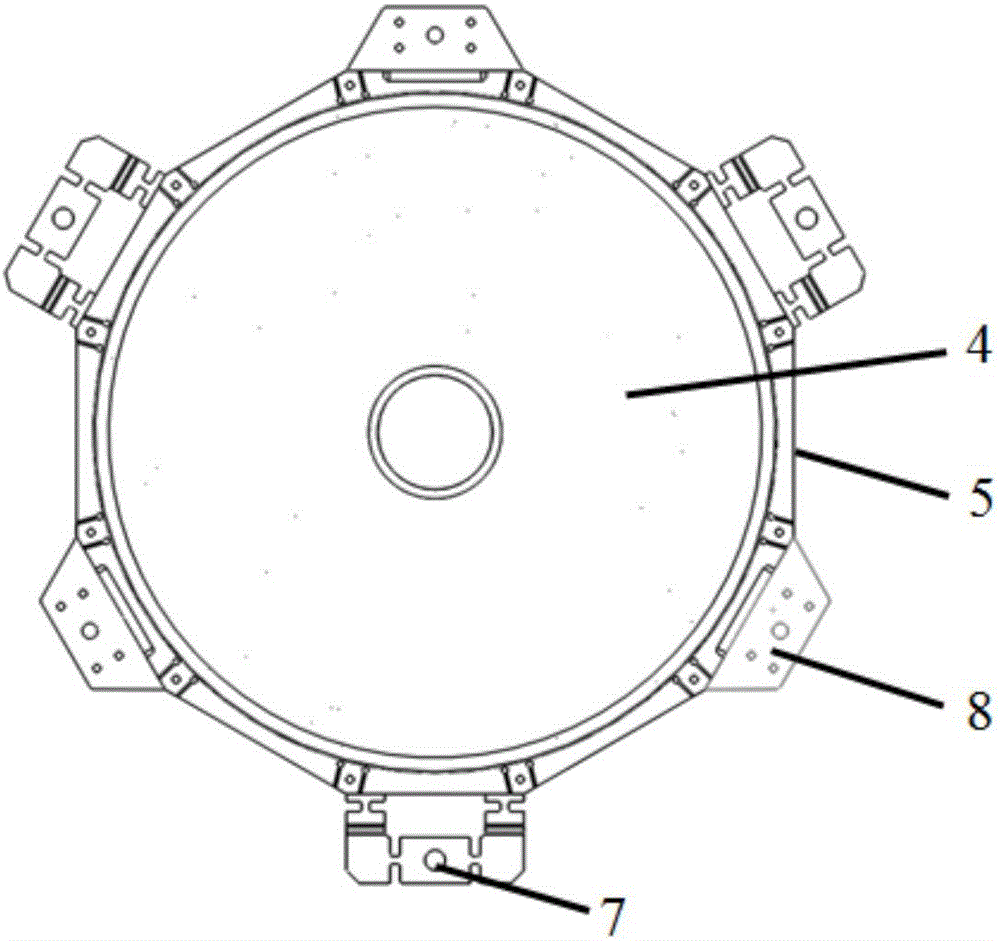

[0035] see Figure 5 , the support plate 5 includes an outer frame 51, an inner frame 52 and a reticulated rib 53; Connected, it can ensure that the reflector has a high weight reduction rate and a high natural frequency. The correction mirror is connected with the inner frame 52 through a threaded hole. The outer frame 51 is provided with three sub-frame mounting plates 8 evenly distributed at 120° and three flexible brackets 7 evenly distributed at 120°, and the adjacent sub-frame mounting plates 8 and flexible br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com