Diamond Wire Slicing Silicon Wafer Breaking Wire Entry Method

A technology of diamond wire cutting and diamond wire, which is applied in the field of diamond wire cutting silicon wafers into the knife, which can solve the problems of wasting silicon wafers, breaking silicon wafers, and increasing costs, and achieve the effect of convenient re-cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

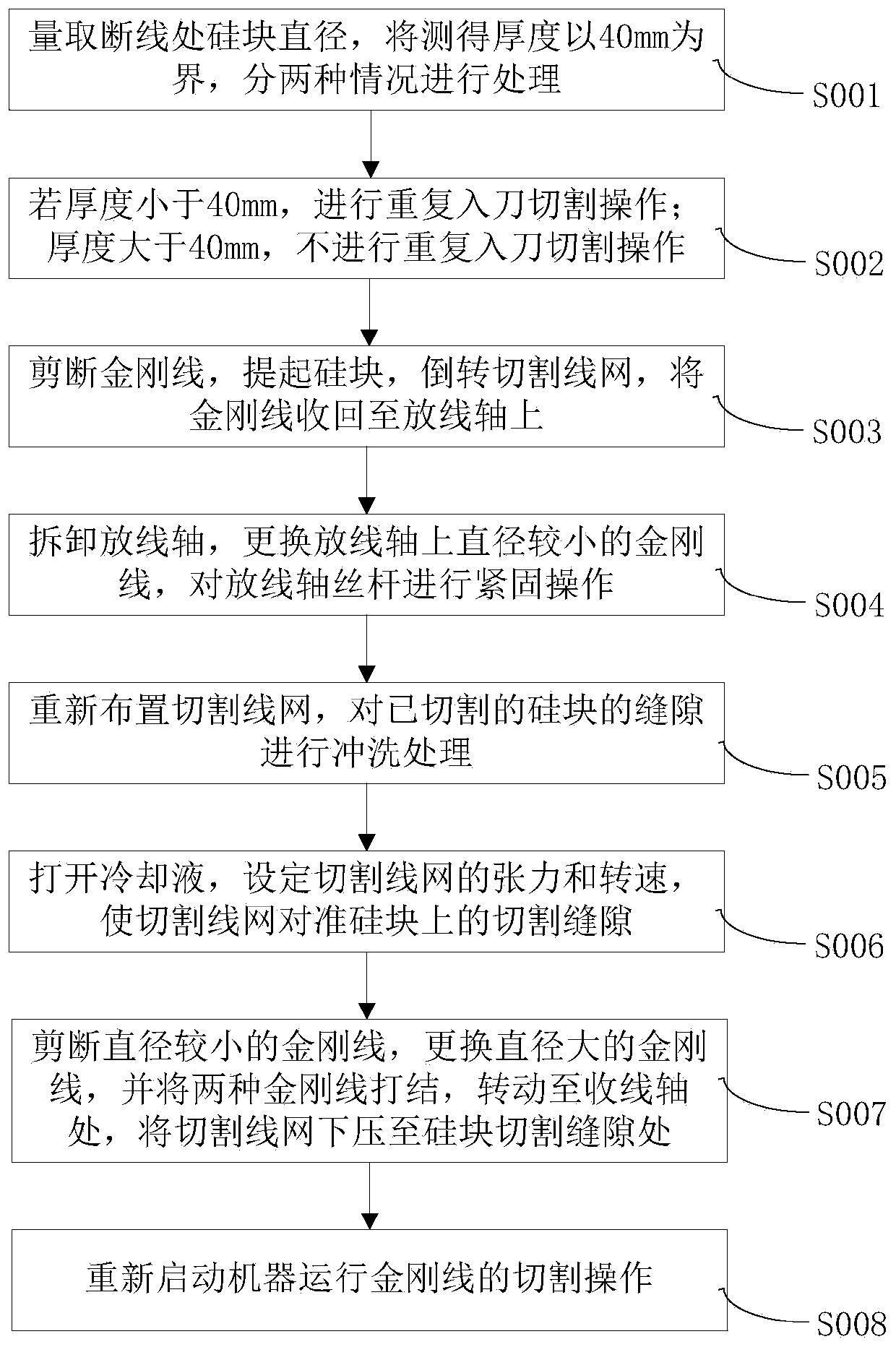

[0038] Further, see figure 1 , as a specific embodiment of the diamond wire cutting method for silicon chip fragmentation provided by the present invention, the diameter of the diamond wire with a smaller diameter is 50-60um. The purpose of changing to a diamond wire with a smaller diameter is to allow the diamond wire to re-enter the gap in the silicon block, and it is easy to insert into the gap, so that the diamond wire with a diameter of 70um is convenient for re-entry.

[0039] Further, see figure 1 , as a specific implementation of the diamond wire cutting method for cutting silicon slices into a knife provided by the present invention, the torque for tightening the lead screw of the pay-off shaft is 80 Nm.

[0040] Further, see figure 1 , as a specific embodiment of the diamond wire cutting silicon chip broken wire feeding method provided by the present invention, the processing in the step 5) includes washing the guide wheel of the cutting wire net, washing the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com