Tire shaping drum stepless expansion and contraction driving device

A driving device and tire molding technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of increasing equipment costs, increasing production costs, and difficult adjustment of forming drums and drum plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

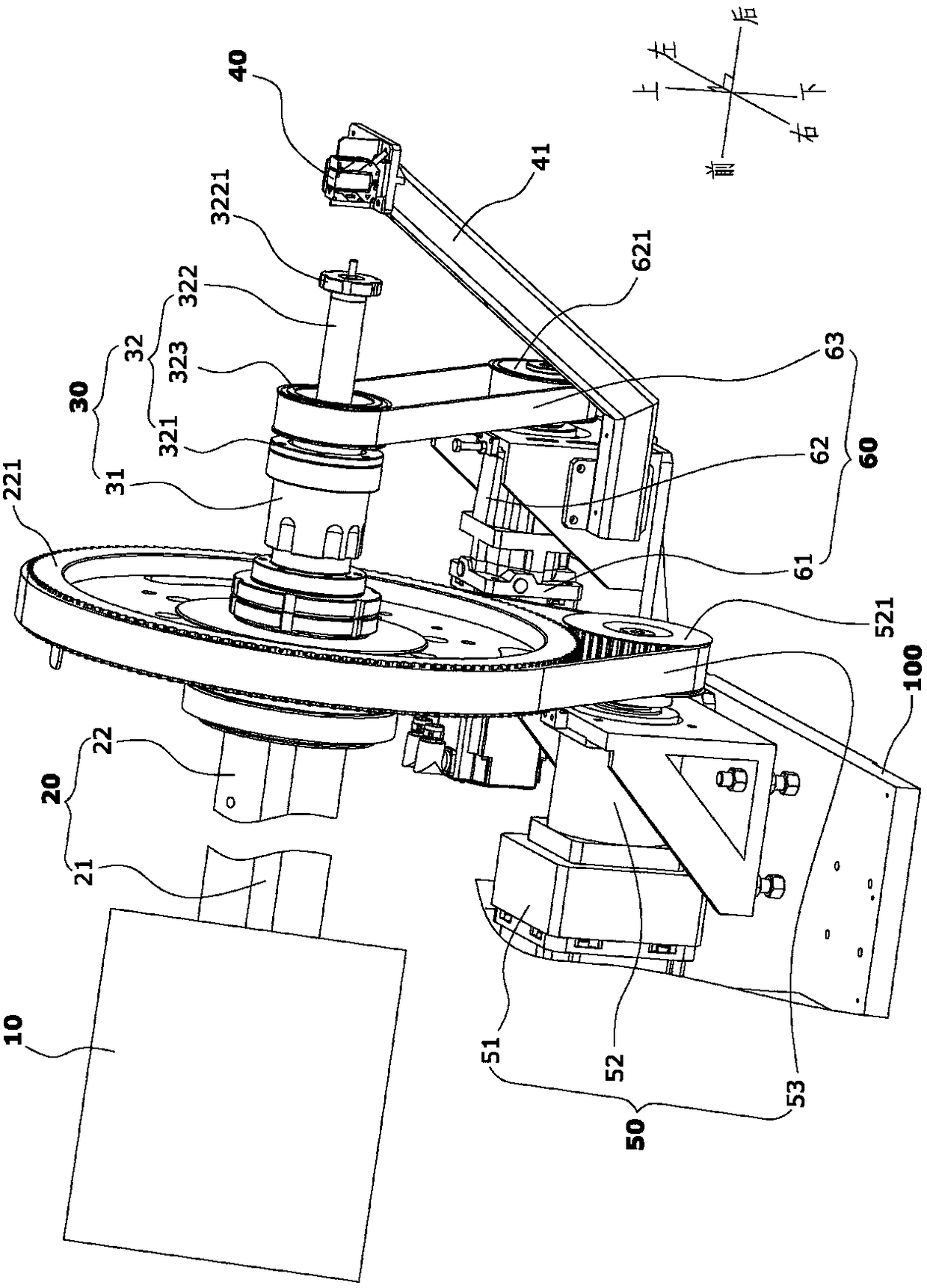

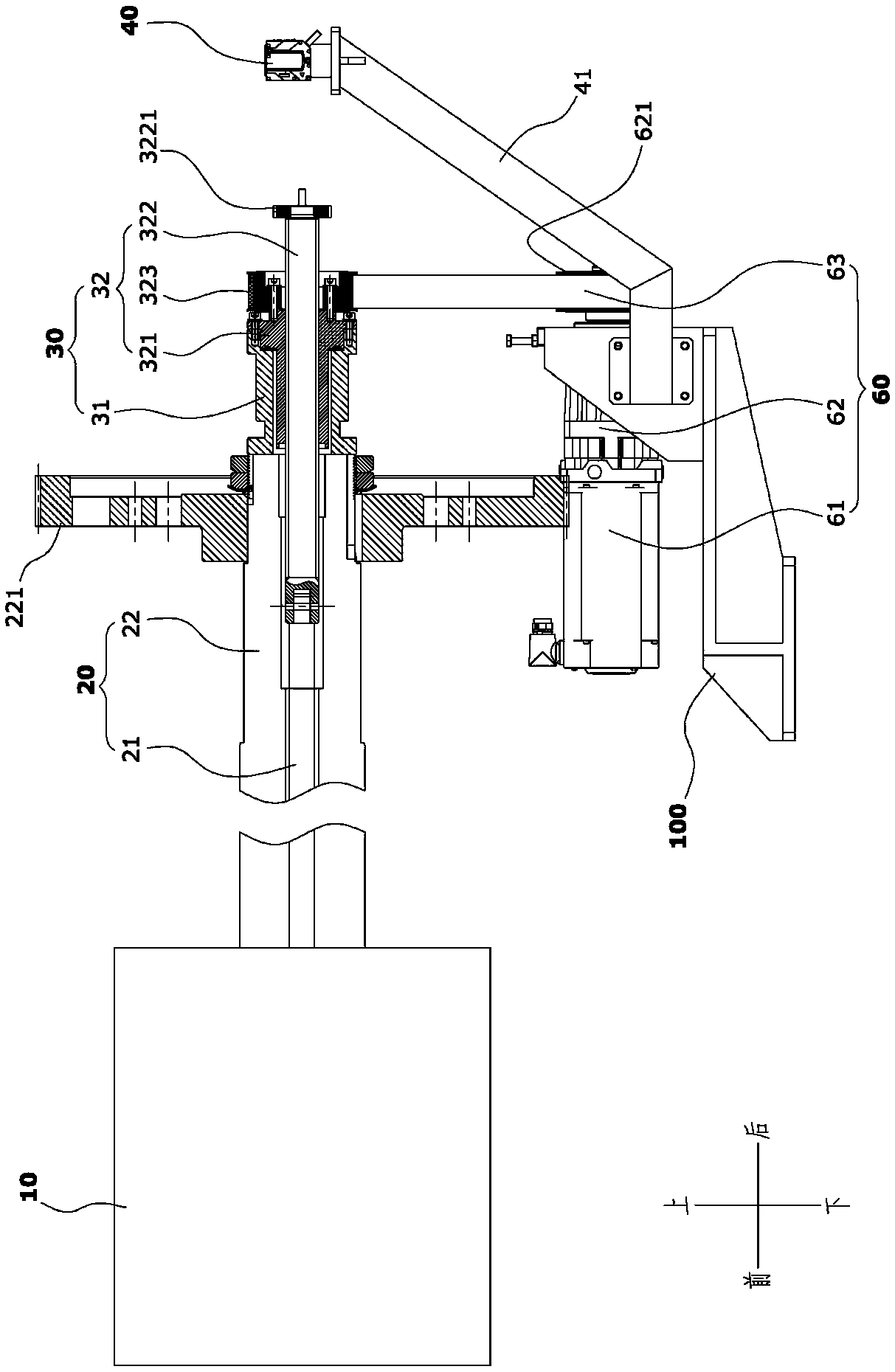

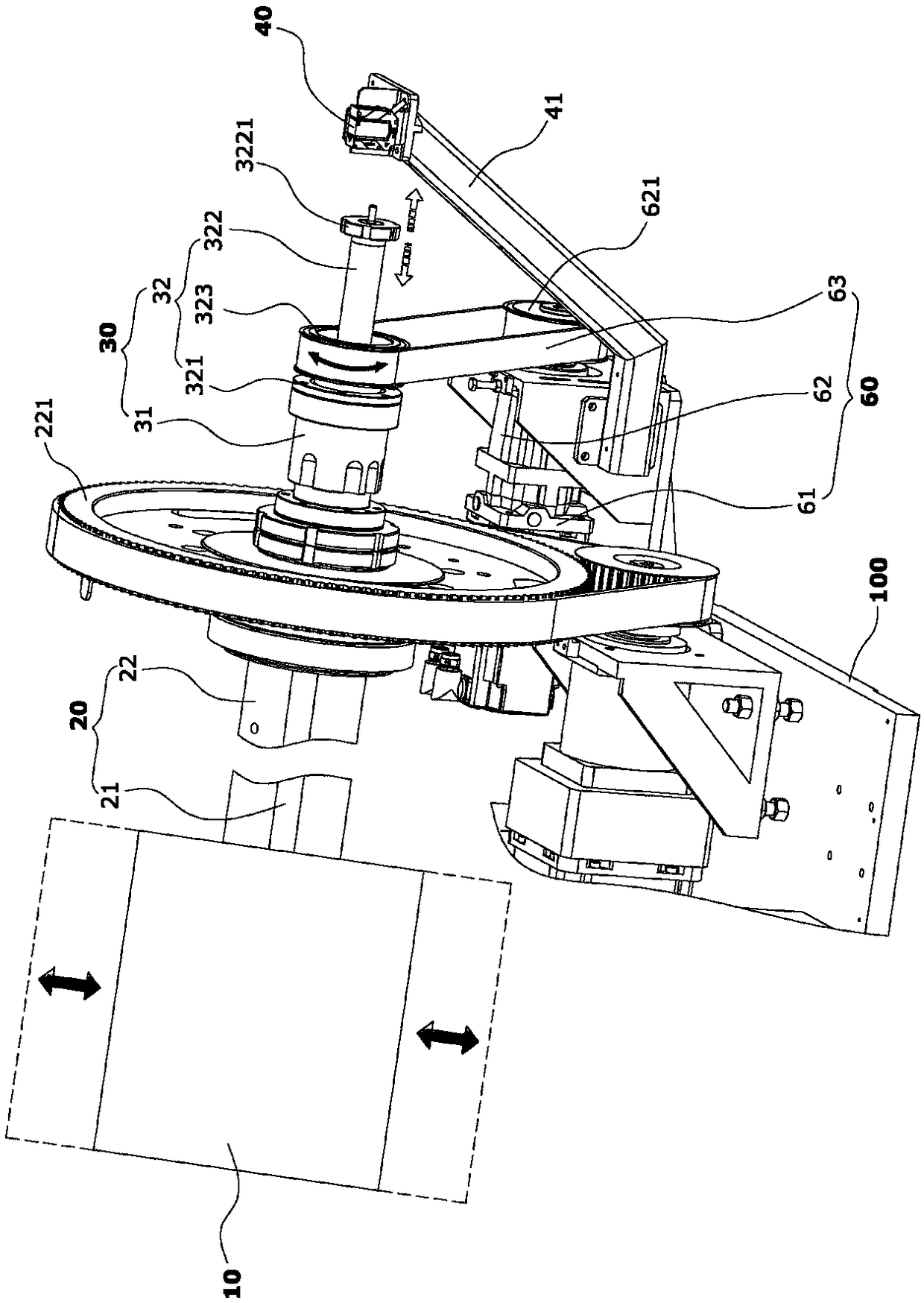

[0021] Such as Figure 1 to Figure 4 The shown tire building drum stepless expansion and contraction driving device is mainly composed of a building drum 10, a main shaft 20, a screw transmission device 30, a displacement sensor 40, a first power unit 50 and a second power unit 60 assembled and connected.

[0022] Such as Figure 1 to Figure 4 As shown, the forming drum 10 of the present invention is mounted on the front of the main shaft 20, the main shaft 20 consists of an inner shaft 21 which can move axially to actuate the radial expansion and contraction of the forming drum 10 and an outer shaft 22 which can drive the forming drum 10 to rotate composition.

[0023] Such as Figure 1 to Figure 4 As shown, the rear portion of the outer shaft 22 of the present invention is fixed with a first driven wheel 221, and a first power device 50 that can ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com