Fireproof floor slab

A floor and bottom plate technology, which is applied to local raised floors, fire rescue, floors, etc., can solve the problems of biological and plant influences, and achieve the effect of preventing fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

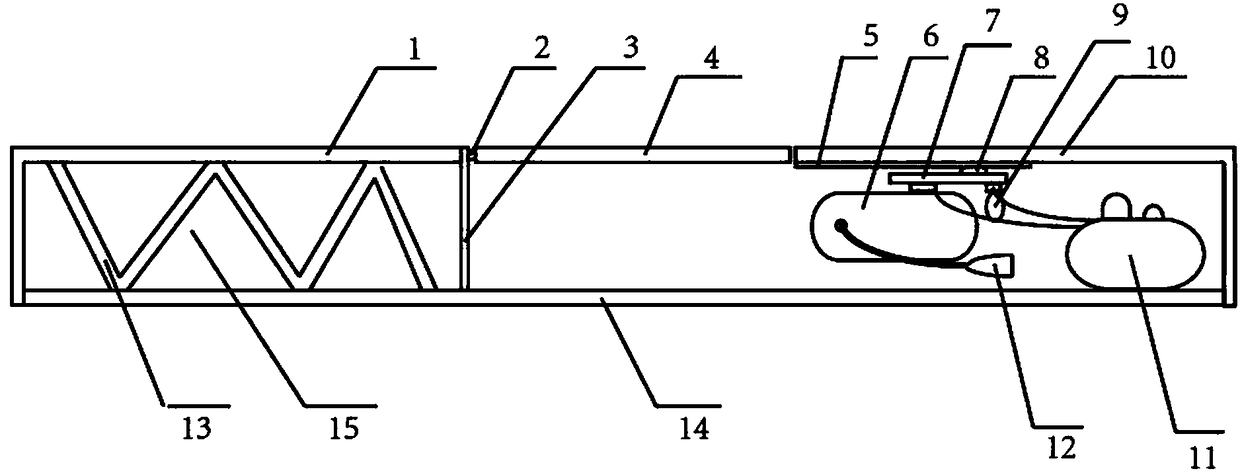

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0011] A fire-resistant floor of the present invention comprises a fixed plate I1, a fixed plate II10, a sliding plate 4, a bottom plate 14, a hollow layer 15, a fire extinguishing device 6, an alarm 9 and a controller 11; the fixed plate I1 and the bottom plate 14 pass through the 14 is connected with the slideway I3; the slideway I3 is connected with the sliding plate 4 through the slider I2; the lower part of the fixed plate II10 is provided with the slideway II5; the slideway II5 is connected with the connecting plate 7 through the slider II8, and the connecting plate 7 is equipped with a fire extinguishing The device 6 and the alarm 9; the fire extinguishing device 6 and the alarm 9 are connected to the controller 11 through a wire; Among them, the fire extinguishing device 6 is provided with a rotary spout 12; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com