Liquid filling system for free forging press

A forging press, free technology, applied in the driving device of the forging press, fluid pressure actuation system components, mechanical equipment, etc., can solve the problem of increasing the volume of the oil tank and the diameter of the oil discharge pipe, increasing the manufacturing cost, high liquid level alarm, etc. problems, to achieve the effect of reducing the diameter, improving the life of system components, and avoiding fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

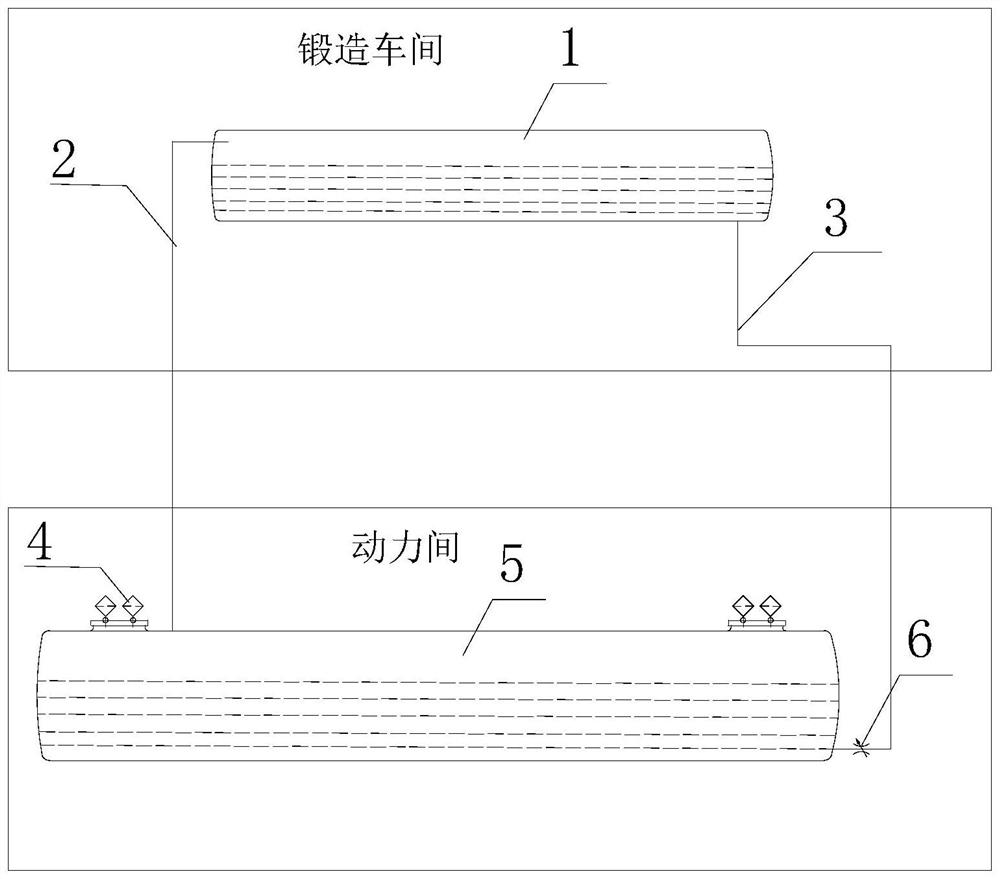

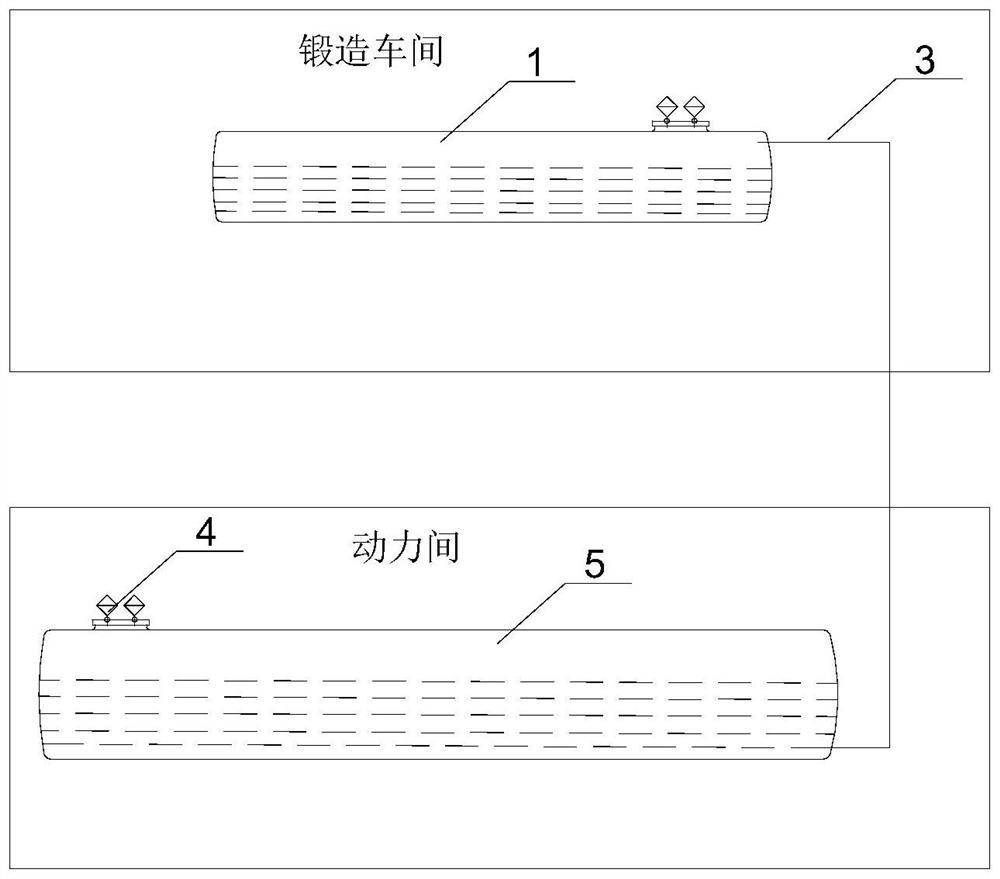

[0030] Such as figure 1 Shown, technical scheme of the present invention is:

[0031] A liquid filling system for open die forging presses, including a liquid filling oil tank 1 located on the top of the equipment in the forging workshop, and a main oil tank 5 located on the ground of the power room;

[0032] An air filter 4 is arranged on the main oil tank 5;

[0033] The main oil tank 5 communicates with the liquid-filled oil tank 1 through the air pipeline 2;

[0034] The main oil tank 5 communicates with the liquid-filled oil tank 1 through the oil discharge pipeline 3;

[0035] A valve is installed on the oil discharge pipeline 3;

[0036] A controller that controls the opening of the valve according to the requirements of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com