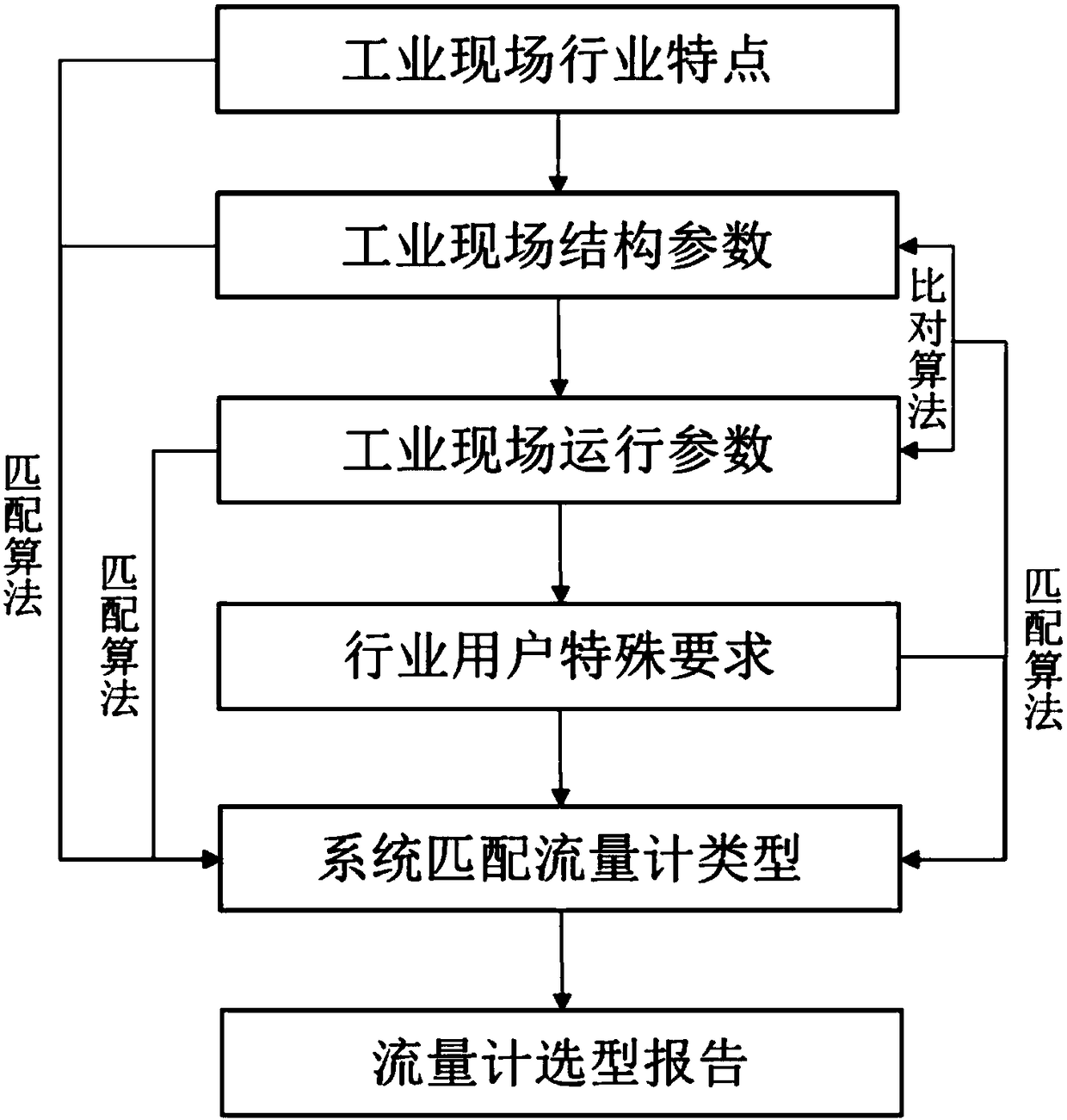

Adaptive industrial flowmeter model selection method

A flowmeter and industrial technology, applied in the field of self-adaptive industrial flowmeter selection, can solve the problems that cannot fully meet the measurement needs of the industrial site, affect the normal production of the industrial site, threaten the production safety of the industrial site, etc., and achieve the selection result. The effect of science, reducing inapplicability and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Industrial Site Fact Sheet

[0148]

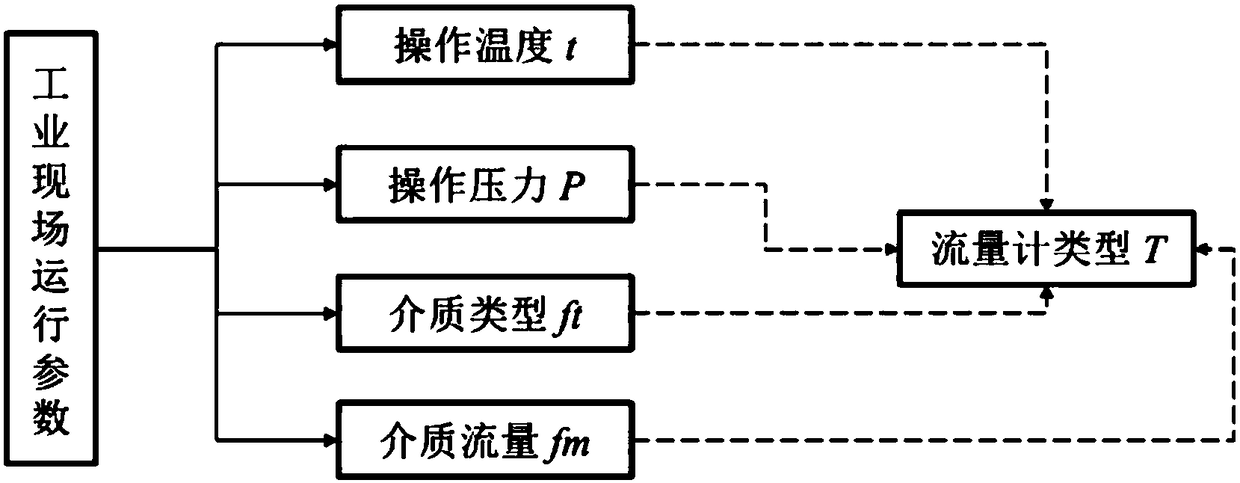

[0149]First of all, according to Item 1, the industrial site belongs to the thermoelectric industry. Under the conditions that the industry has determined, according to the formula (1.1) ~ formula (1.3) in step 1, the mass flowmeter can be automatically eliminated, and the flowmeter that can be matched by this industry For electromagnetic flowmeter, differential pressure flowmeter, ultrasonic flowmeter, vortex flowmeter, positive displacement flowmeter, thermal flowmeter.

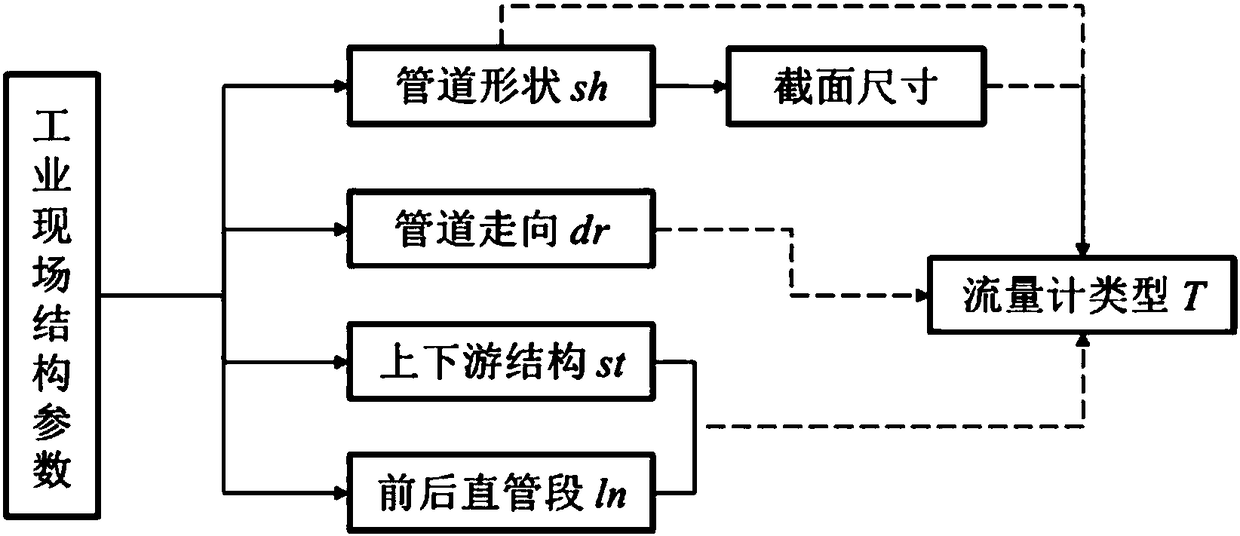

[0150] According to items 2 to 9, the structure of the upstream straight pipe section and the downstream straight pipe section of the measuring pipeline are both single elbows, the length of the straight pipe section is 20D, and the flow field is fully developed. According to the formula (1.8), the matching flowmeter types are electromagnetic flowmeter, Differential pressure flowmeter, ultrasonic flowmeter, vortex flowmeter, positive displacement flowmeter, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com