Lock tongue assembly assembling machine and assembling method thereof

A technology for assembly machines and components, applied in assembly machines, construction locks, metal processing equipment, etc., can solve problems such as low efficiency, achieve the effects of improving quality, improving assembly efficiency, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

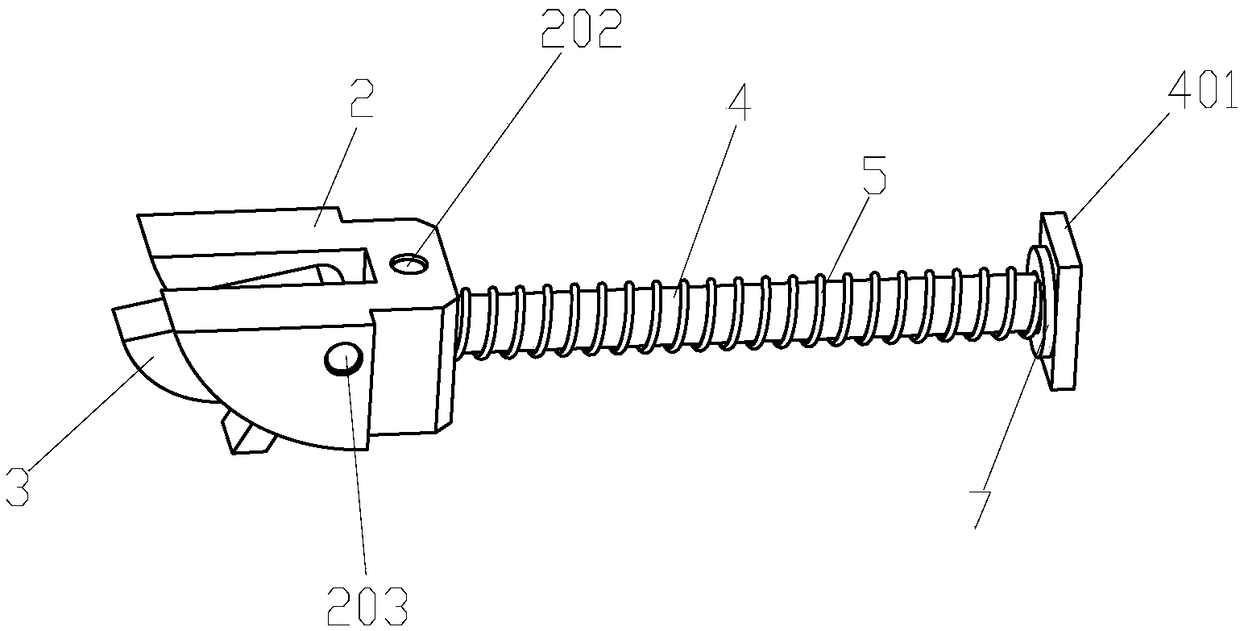

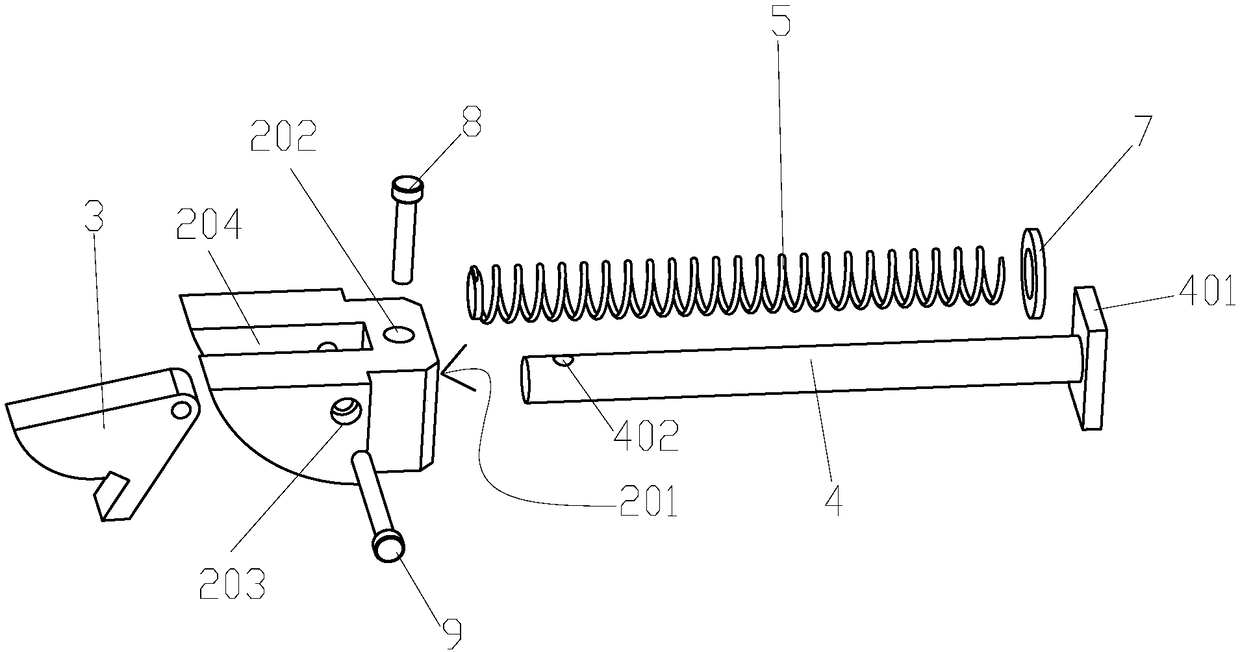

[0040] The household bolt assembly at least includes a large bolt 2 and a lock bar 4, and may also include a small bolt 3 hinged on the big bolt 2, and a spring 5 and a washer 7 are sleeved on the lock bar 4, such as figure 1 and 2 shown.

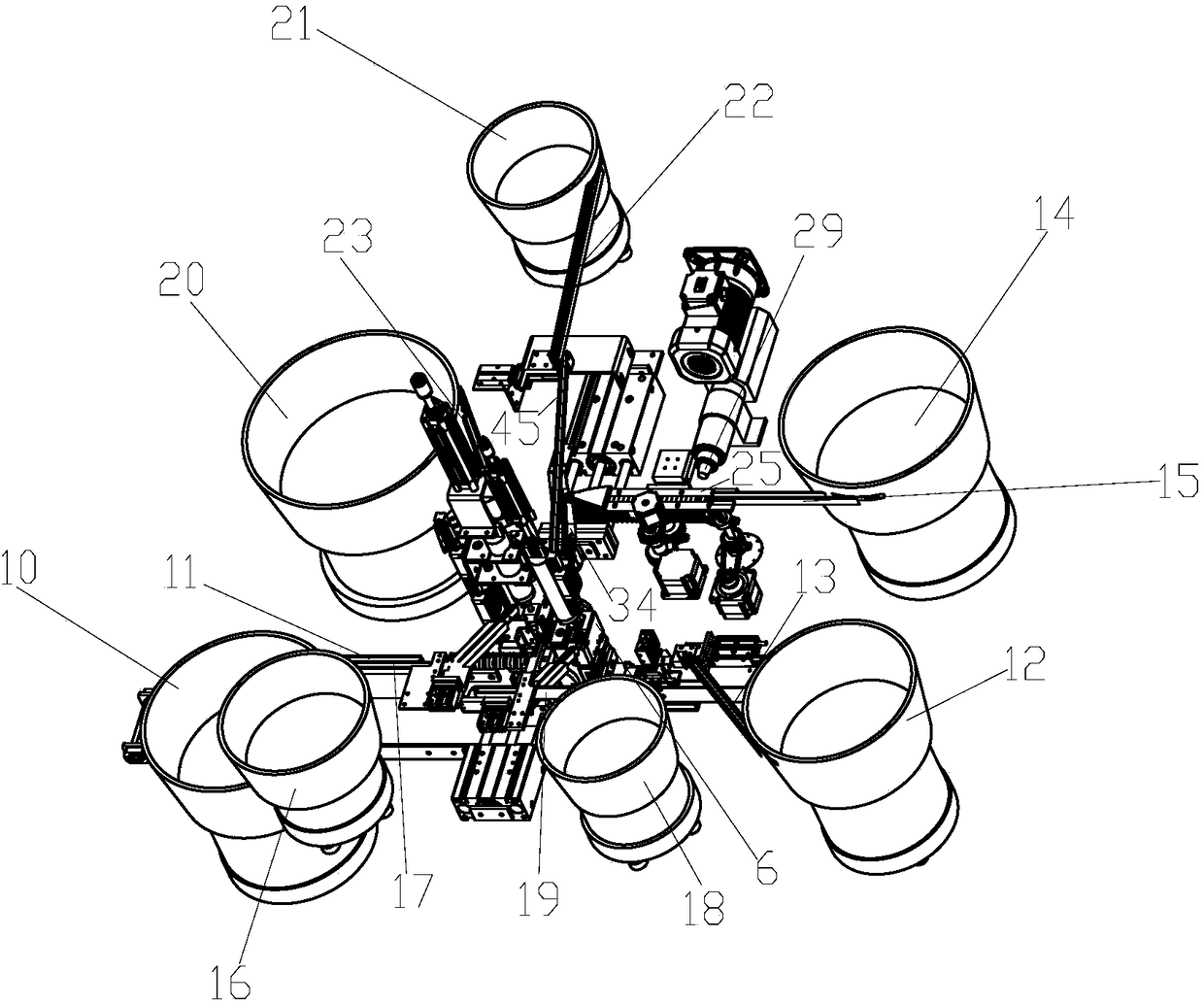

[0041] An assembly machine for the above-mentioned deadbolt assembly, such as Figure 3 to Figure 11 As shown, it includes an organic platform, which is not shown in the figure, and the first vibrating plate 10 for loading a plurality of large lock tongues 2 and the first sliding plate connected with the first vibrating plate 10 are respectively provided on the machine platform. Rail 11, the second vibrating plate 12 of a plurality of small lock tongues 3 and the second sliding rail 13 connected with the second vibrating plate 12, the third vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com