Hamaguri-ba knife grinding method

A technology of clam blades and knives, which is applied in the field of clam blade grinding, which can solve problems such as increased difficulty, difficulty in controlling force or angle, and inability to grind out the curved angle of clam blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

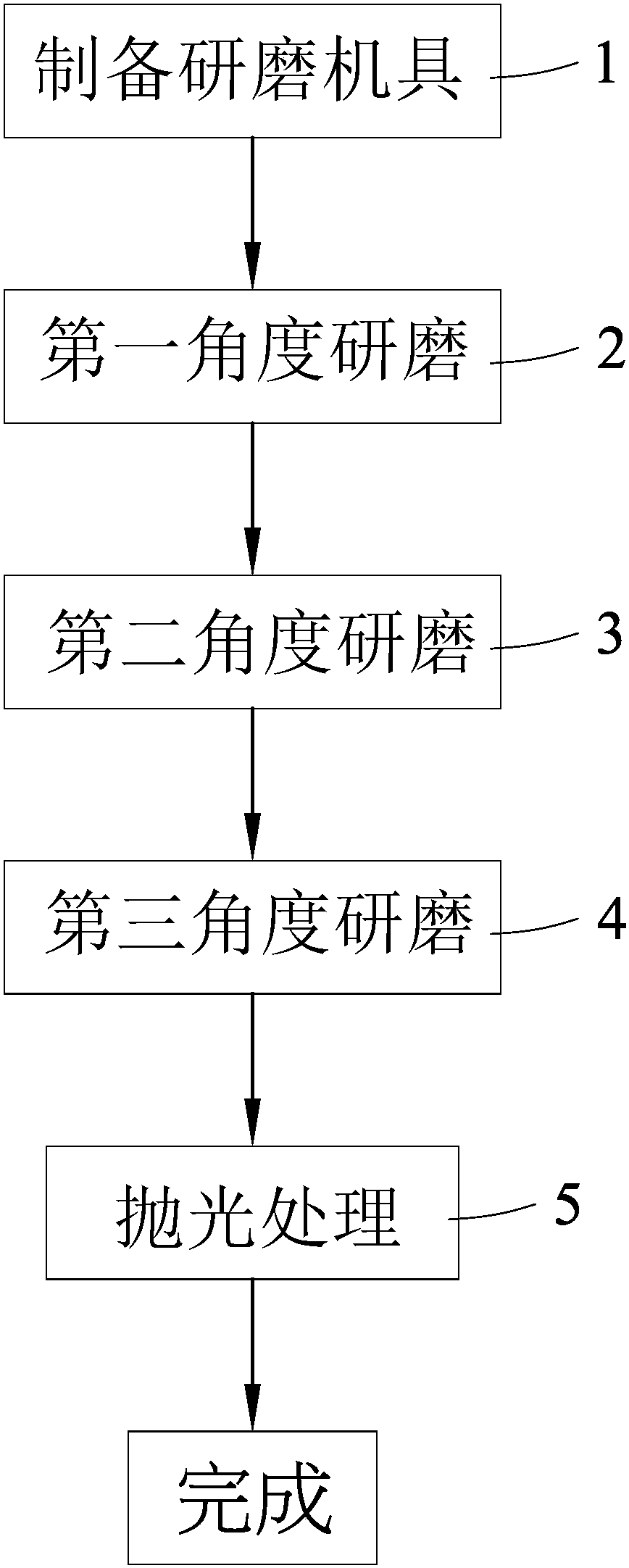

[0029] The present invention relates to a method for grinding clam blades, the steps of which include:

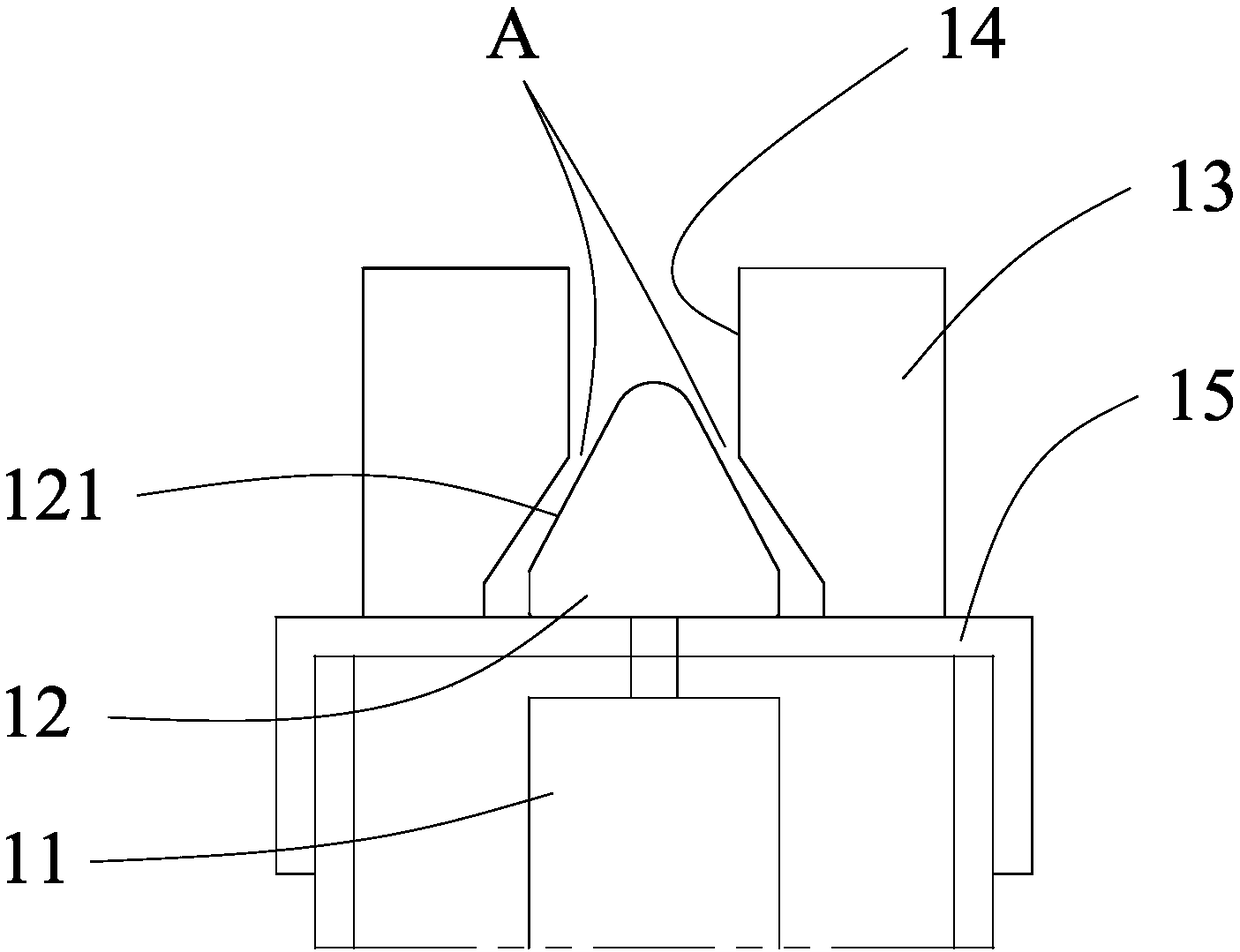

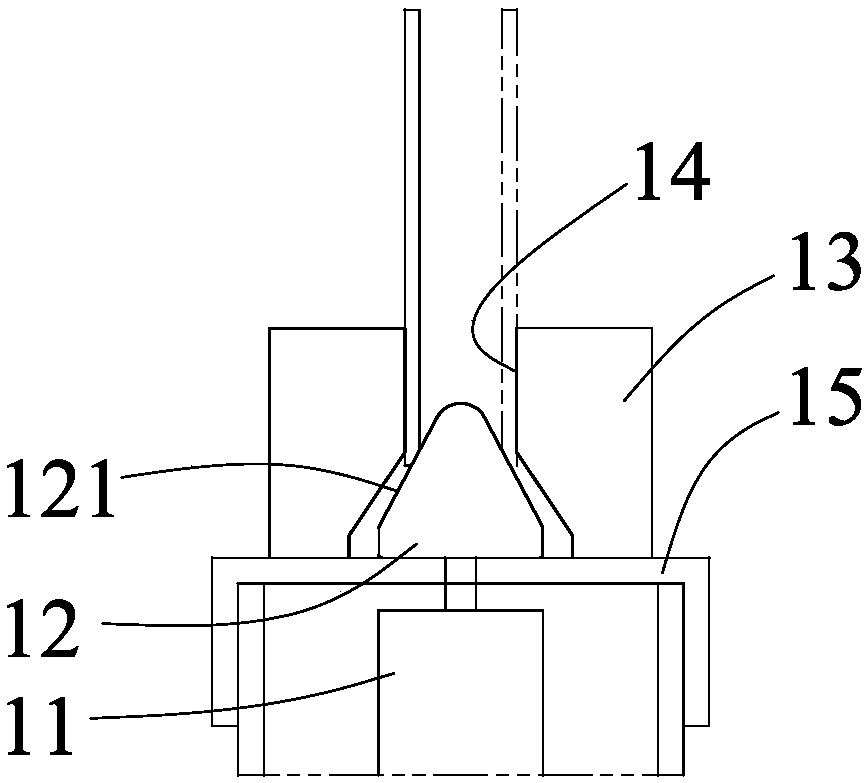

[0030] One preparation grinding machine tool 1, [see figure 1 and figure 2 ] The grinding tool has a driver 11, and three sets of shank grinding parts 12 and auxiliary guide blocks 13 respectively matched with the shank grinding parts 12, and the three sets of shank grinding parts 12 are used to be installed on the driver 11 , the outside of the shank grinding piece 12 has a tapered grinding surface 121, and the taper angles of the three sets of shank grinding pieces 12 are respectively 22°-28°, 12°-18° and 3°-7°. Auxiliary guide blocks 13 are respectively arranged on both sides of each grinding piece with handle 12, and a vertical guide surface 14 is formed on the side of each auxiliary guide block 13 corresponding to the grinding piece with handle 12, and each guide surface 14 Located above the center position of the grinding surface 121, a V-shaped angle is formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com