Beverage filling system

A filling system and beverage technology, applied in packaging, liquid materials, transportation packaging, etc., can solve problems such as poor work efficiency and inability to ensure continuous work, and achieve the effects of reducing working time, ensuring sealing quality, and facilitating feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and the best embodiments.

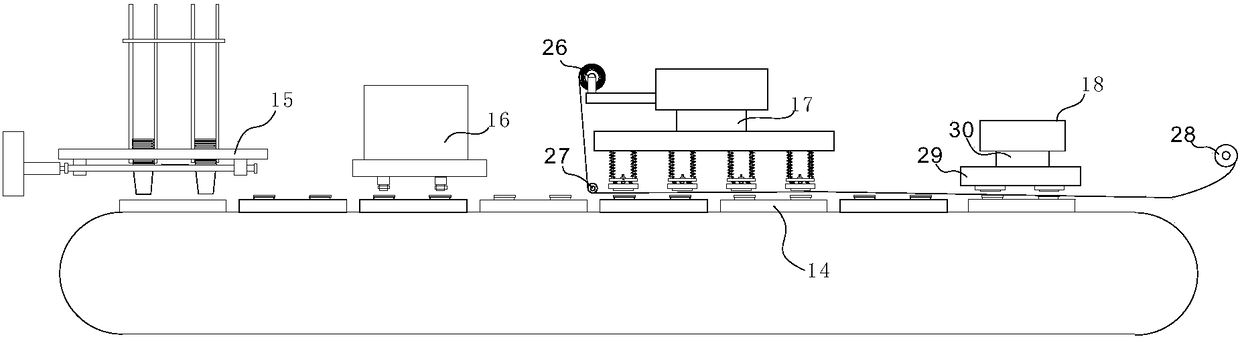

[0019] As shown in the figure, the present invention includes a conveyor belt 14, a cup feeder 15, an automatic batching and filling machine 16, a heat sealing machine 17 and a cutting machine 18, which are sequentially arranged above the conveyor belt.

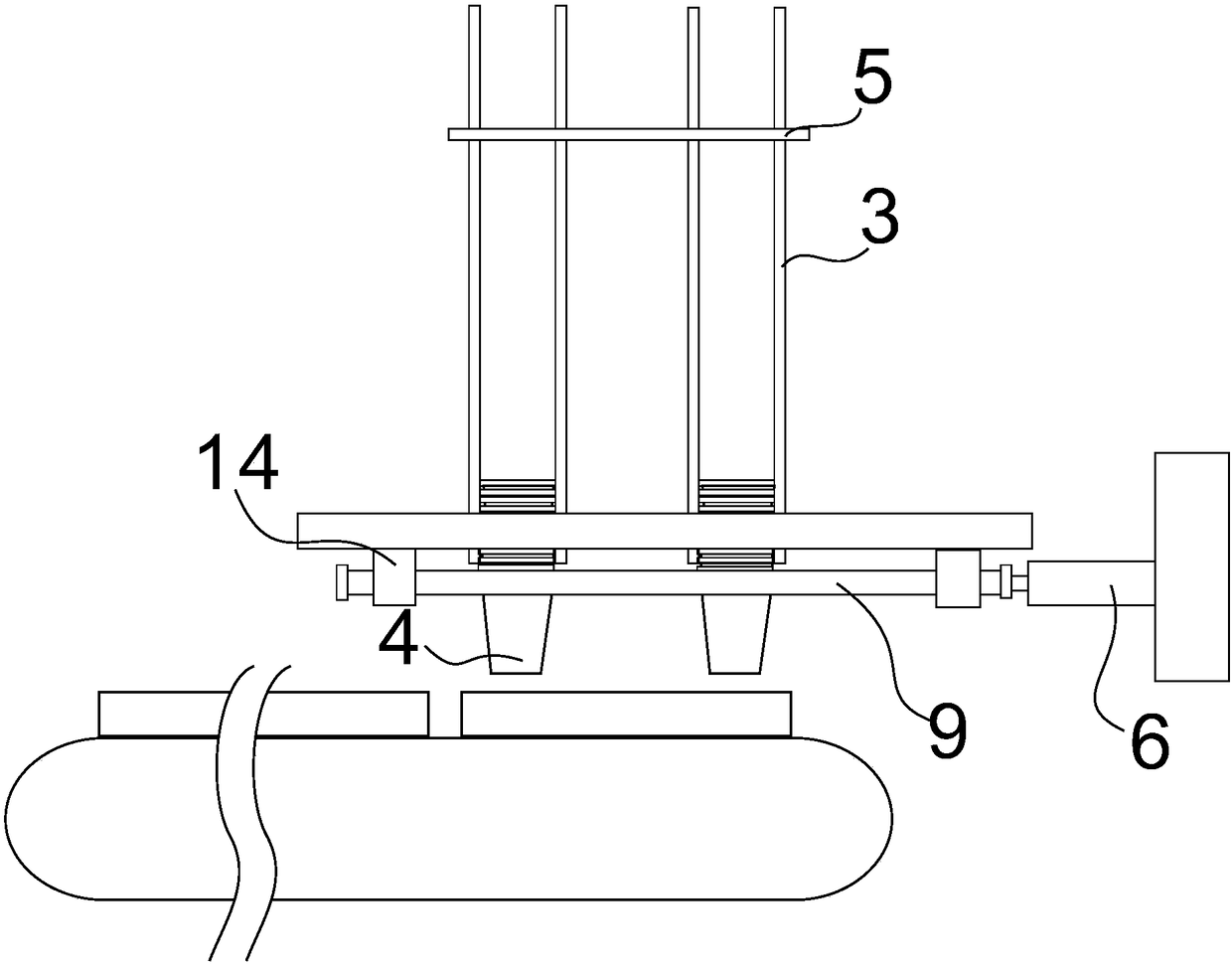

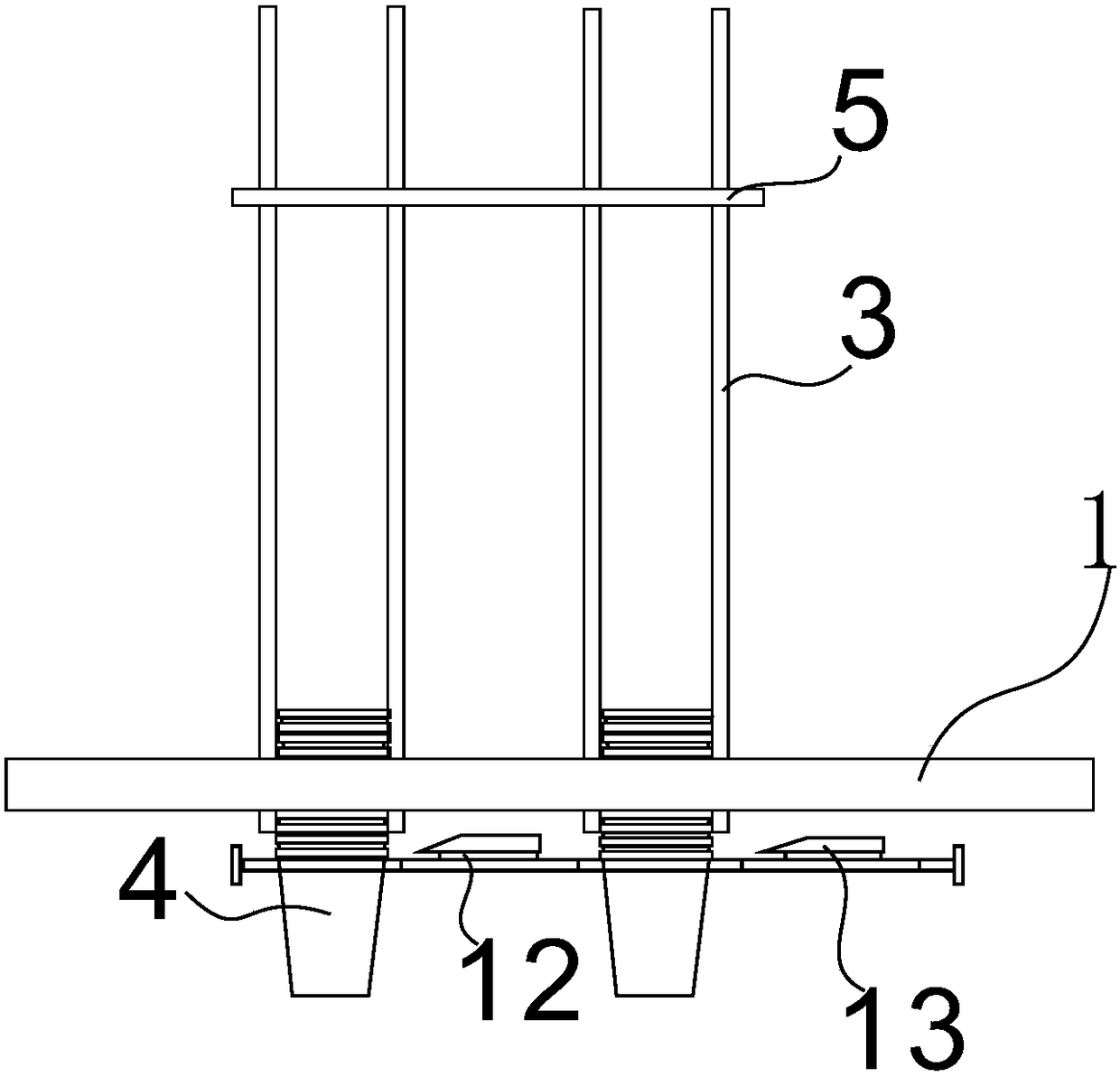

[0020] The feeder includes a top seat 1 and a cup feeding mechanism arranged under the top seat. The top seat is provided with a plurality of leaky cup circular holes 2 side by side, and four equiangularly distributed limiters are fixed along the edge of the leaky cup circular hole. bit post 3,

[0021] The stacked cups 4 are limited by the guide column, and the top of the limit column extends upwards, which is convenient for storing more cups in the limit column. The horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com