Vehicle overwidth detection method for back cantilever three-dimensional parking space

A three-dimensional parking and detection method technology, which is applied in the direction of parking buildings, measuring devices, instruments, etc., can solve the problems of misreporting and misreporting, poor economy, etc., and achieve the effect of reducing equipment cost, high cost performance, and reducing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

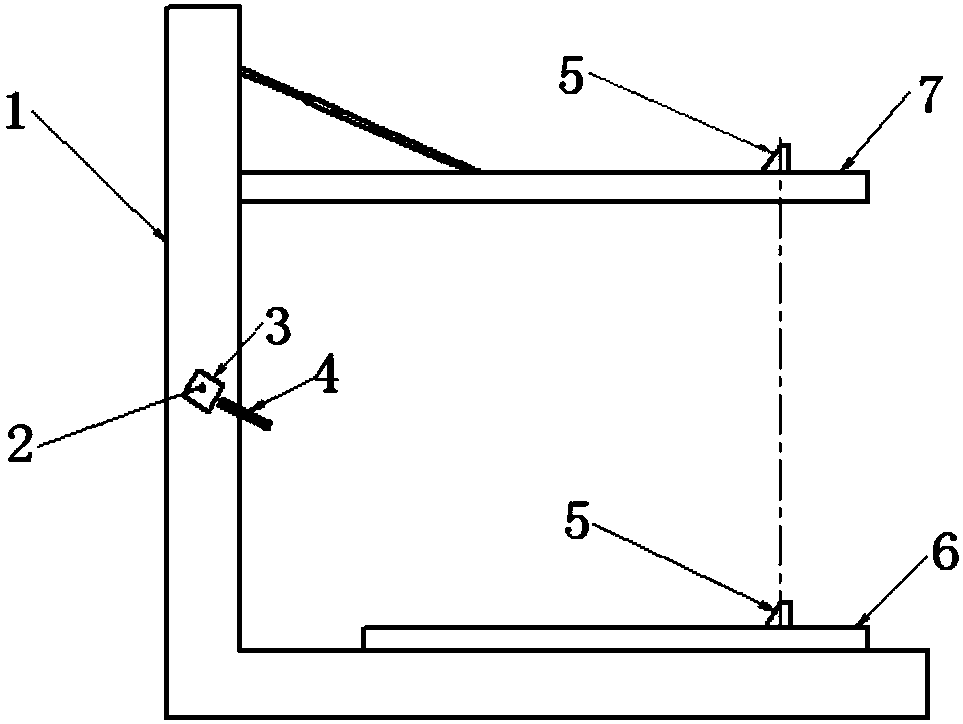

[0030] This embodiment is a vehicle over-width detection method for a three-dimensional parking space with a rear cantilever. The specific implementation process takes a parking unit with 3 rows, two floors and 5 parking spaces as an example. The five parking spaces in the parking unit are numbered sequentially by floor, specifically the two traversing parking spaces on the first floor are 101 and 102, and the three lift parking spaces on the second floor and the traversing parking spaces on the first floor are 201 and 202 in the same direction. , 203, a total of 5 parking spaces, with the entrances and exits of each parking space in the parking unit as the front.

[0031] This embodiment takes the detection of 201 parking spaces and 101 parking spaces as an example to describe the specific implementation process in detail:

[0032] Step 1, install the photoelectric reflection device.

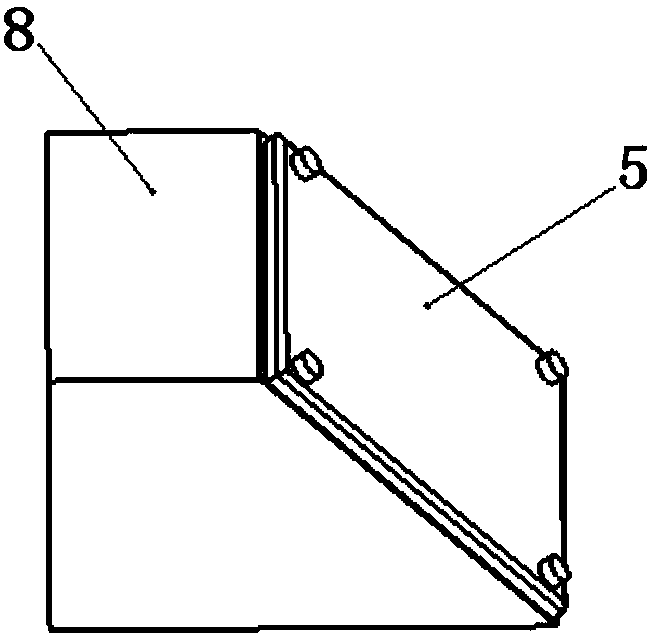

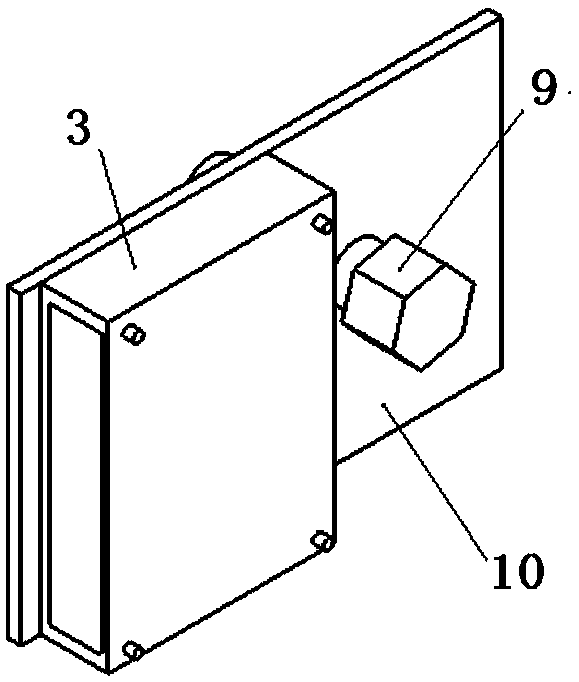

[0033] There are four photoelectric reflection devices, all of which are composed of a pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com