Leaf vegetable harvester capable of harvesting leaf vegetables with roots

A technology for harvesters and vegetables, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc. It can solve the problems of damage to edible parts of plants, waste of storage space, and pits poked out of stems, etc., to improve food consumption. value, the effect of reducing the chance of extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

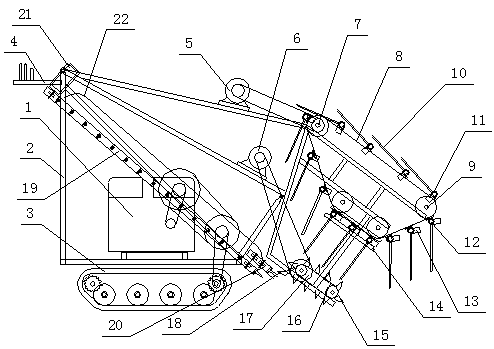

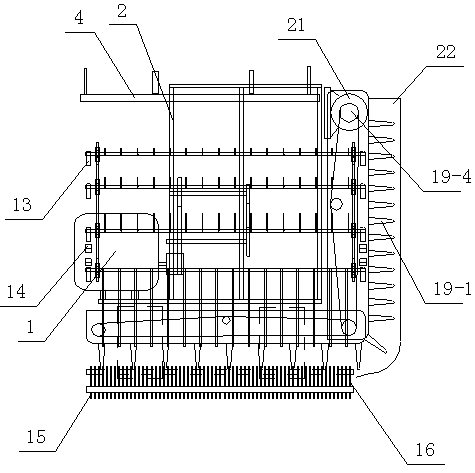

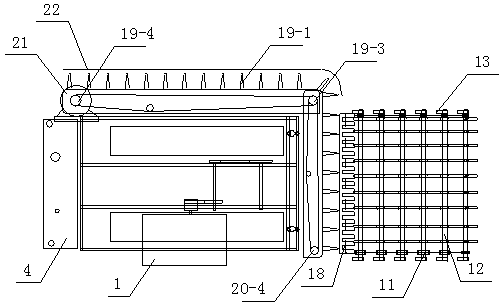

[0037] refer to Figure 1 to Figure 10 , the present invention provides a leaf vegetable harvester for harvesting with roots, which includes a frame 2, a vegetable lifting mechanism, a conveying mechanism, a vegetable removing board 18 and a vegetable supporting mechanism;

[0038] Gasoline engine 1 is used for providing power for machine walking;

[0039] The frame 2 is used to install and fix other components, and the bottom of the frame 2 is provided with a walking track 3;

[0040] The operating platform 4 is used to manipulate the various working parts of the machine;

[0041] The vegetable lifting mechanism is installed on the front end of the frame 2 for digging vegetables, including a vegetable digging chain 16 arranged obliquely, and the vegetable digging chain is provided with teeth 15 that can extend into the mud and dig up vegetables by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com