Optical blue glass cutting equipment

A technology for cutting equipment and blue glass, which is applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., and can solve the problems of blue glass support and unsatisfactory anti-skid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] refer to Figure 1 to Figure 4 Embodiments of the present invention will be further described.

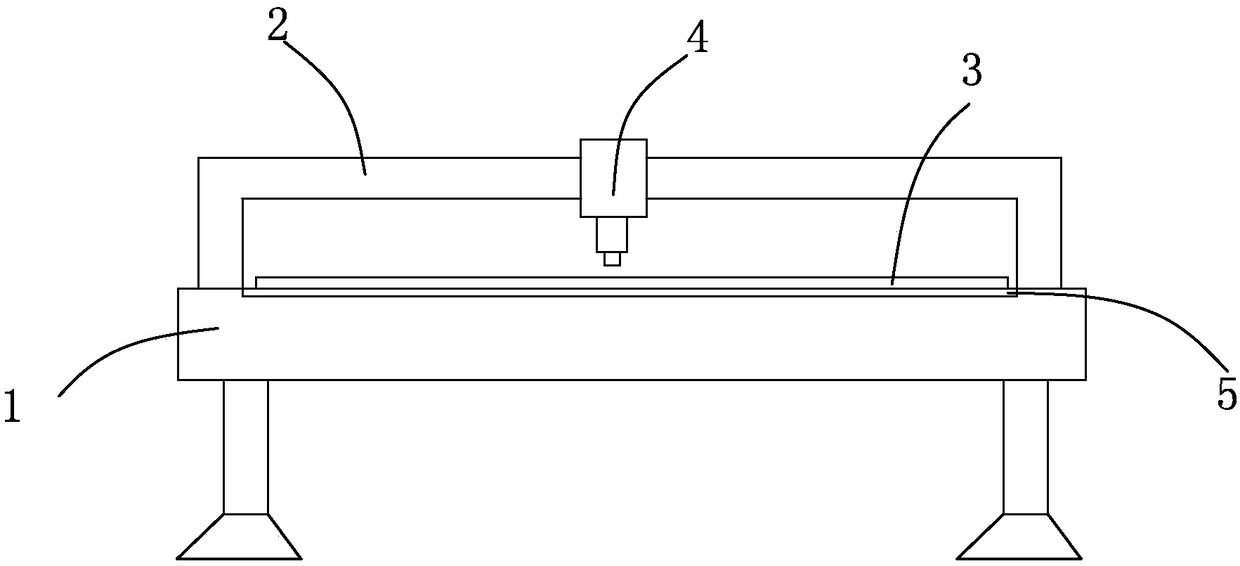

[0016] The specific structure of this embodiment includes a platform 1 for placing the blue glass 3, a gantry 2 placed on the platform 1 for installing the cutting head 4, the cutting head 4 and the gantry 2 are slidingly connected, and the gantry 2 and the platform 1 slide connect.

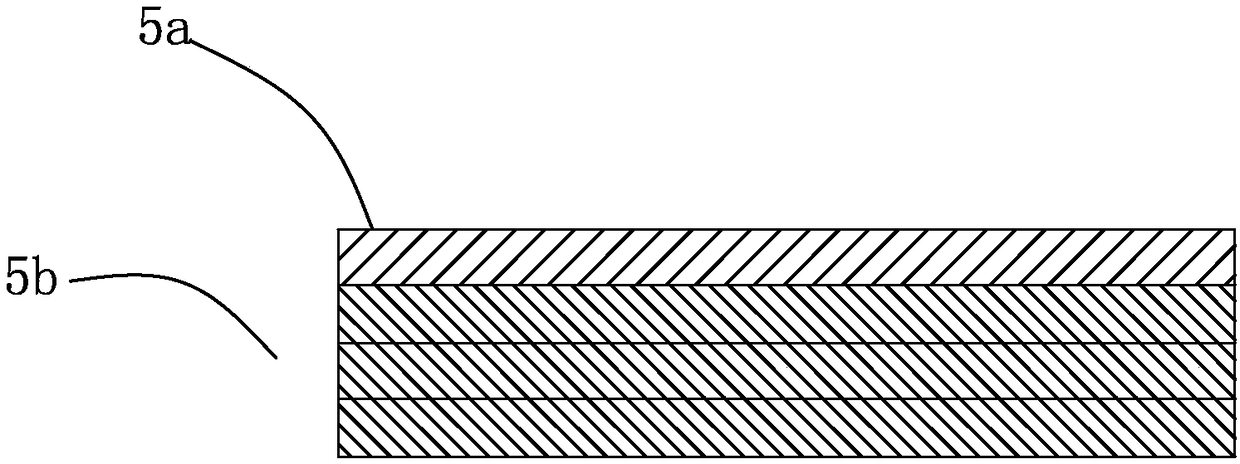

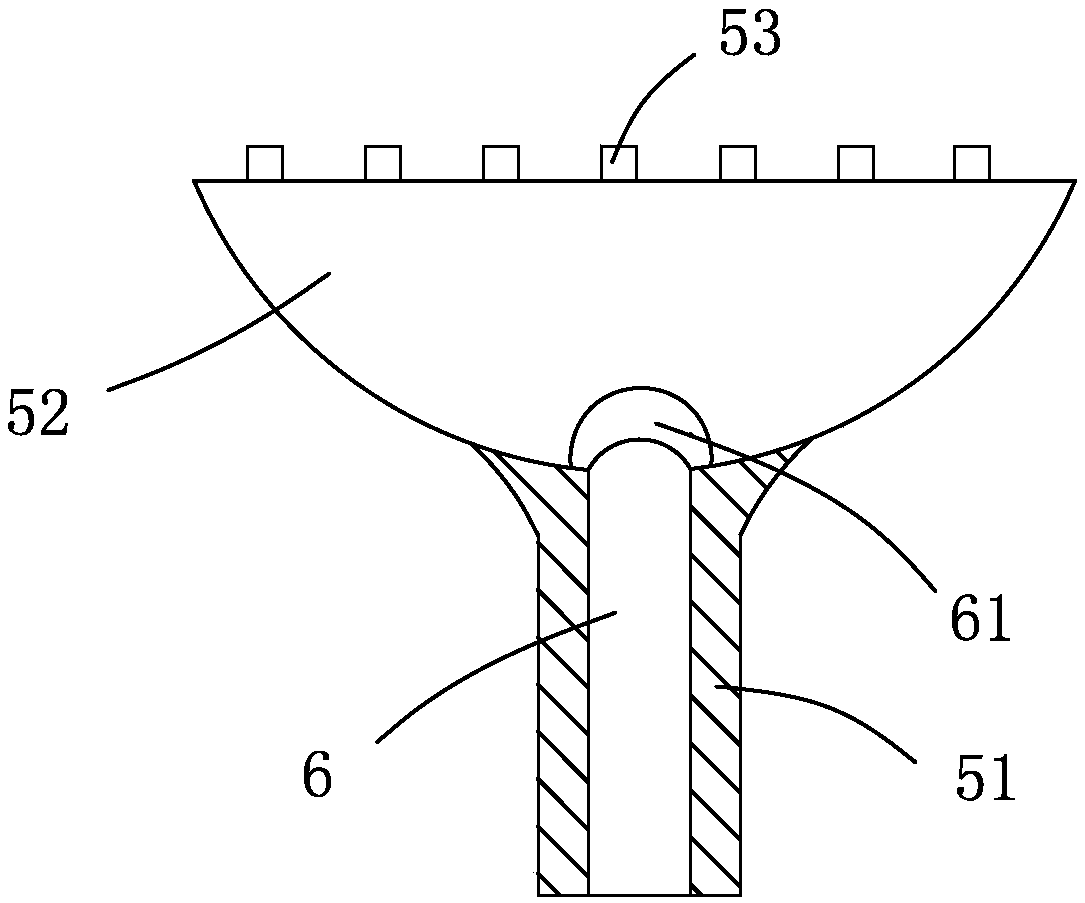

[0017] The platform 1 is provided with a support pad 5 for the interference of the blue glass 3. The support pad 5 includes a support layer 5b and a slow pressure layer 5a. The slow pressure layer 5a is composed of a number of slow pressure bodies arranged and combined. And the contact portion 52, the contact portion 52 is semicircular, and the top surface of the contact portion 52 is provided with some upper bumps 53, the bumps 53 include a sleeve 531 with a through hole and a core rod 532 filling the sleeve 531, the sleeve 531 A number of anti-slip rings 530 are provided on the top end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com