A vehicle suspension system including a negative stiffness device and its control method

A vehicle suspension and control method technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems that the negative stiffness device can not be fully utilized, can not be guaranteed, and the adjustment of the initial state is not considered, and the structure is simple , easy to design, and the effect of improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

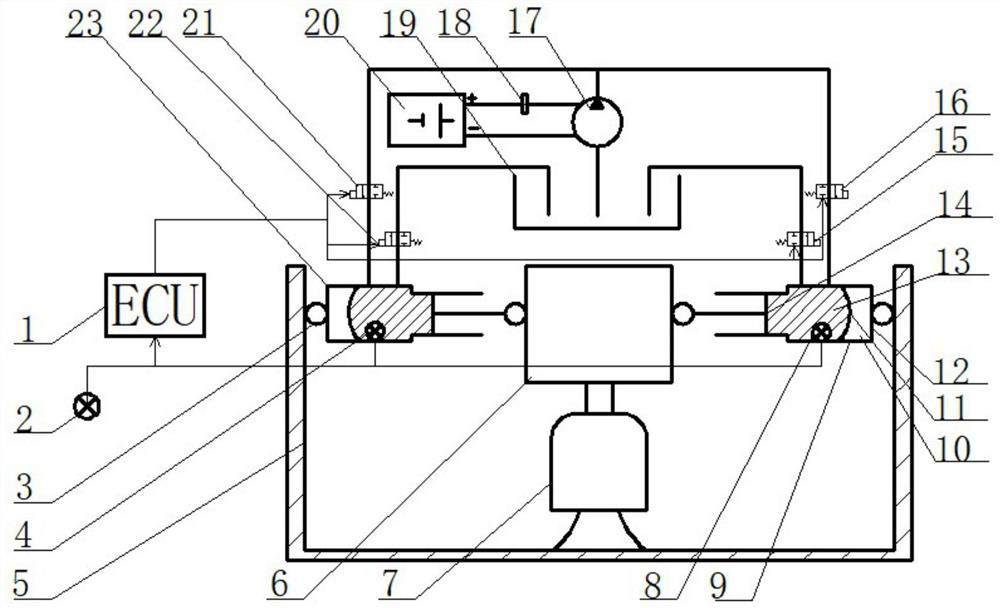

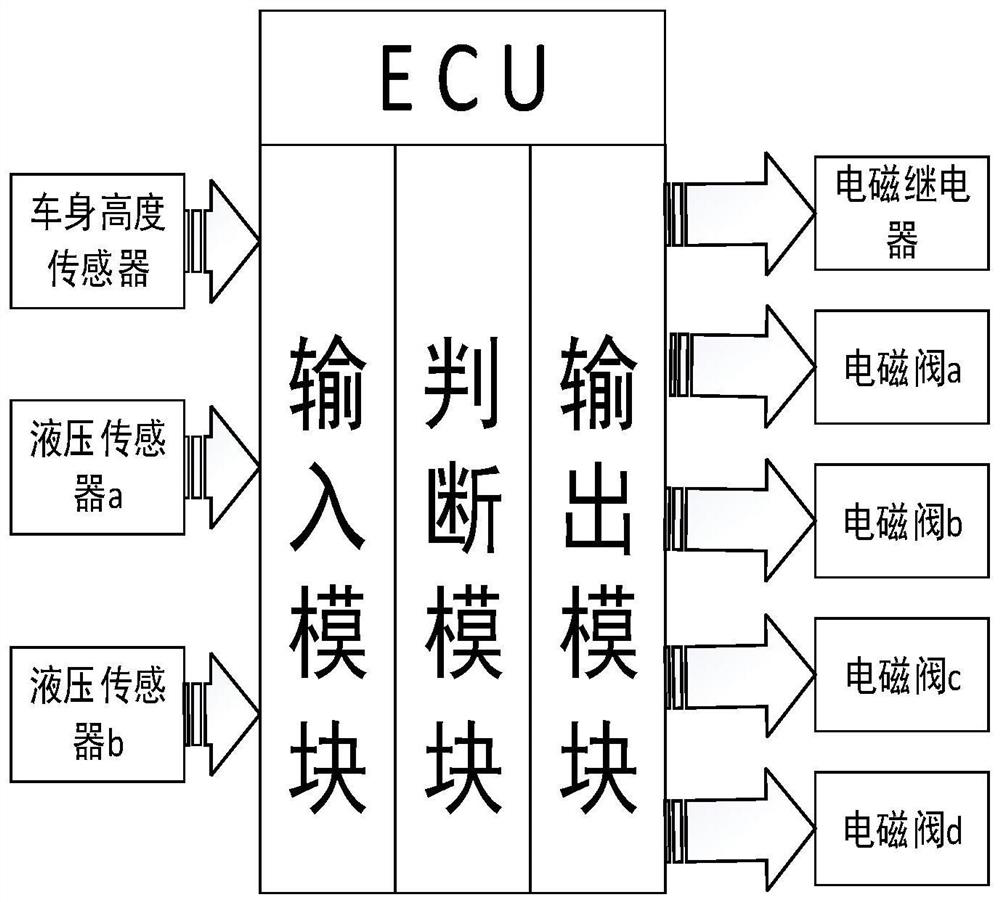

[0034] figure 1 Shown is an embodiment of the vehicle suspension system including the negative stiffness device of the present invention, and the vehicle suspension system including the negative stiffness device includes a detection mechanism, a control unit and an actuator.

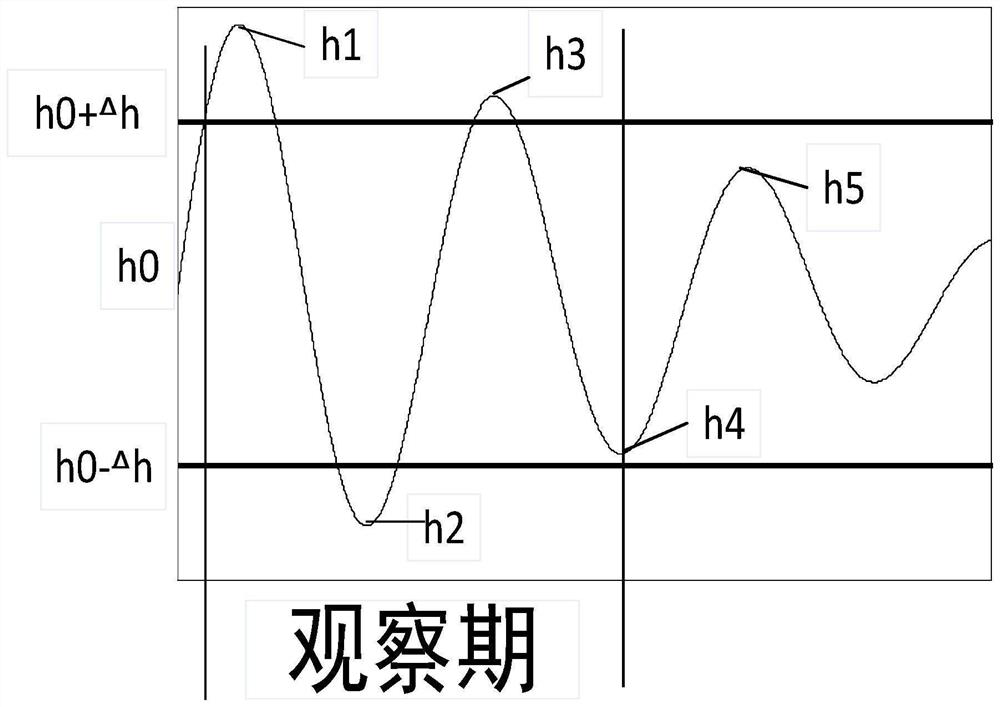

[0035]The detection mechanism includes a vehicle body height sensor 2, a hydraulic sensor a4, and a hydraulic sensor b8. The vehicle body height sensor 2 is used to perceive the vehicle body height information; the hydraulic pressure sensor a4 and the hydraulic pressure sensor b8 are respectively installed in the left cylinder 23 and the right cylinder 9, and the hydraulic pressure sensor a4 is used to detect the hydraulic pressure of the left cylinder 23; The sensor b8 is used to detect the fluid pressure of the right cylinder 9 . Initially, the air suspension 7 adjusts the height of the vehicle body 6 so that the left cylinder 23 and the right cylinder 9 are perpendicular to the vehicle body 6. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com