Support machine for pipeline repair

A mechanical and pipeline technology, applied in the field of support machinery for pipeline repair, can solve the problems of potential safety hazards, pipelines cannot be fixed and supported, etc., and achieve the effect of preventing deviation, preventing changes, and preventing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

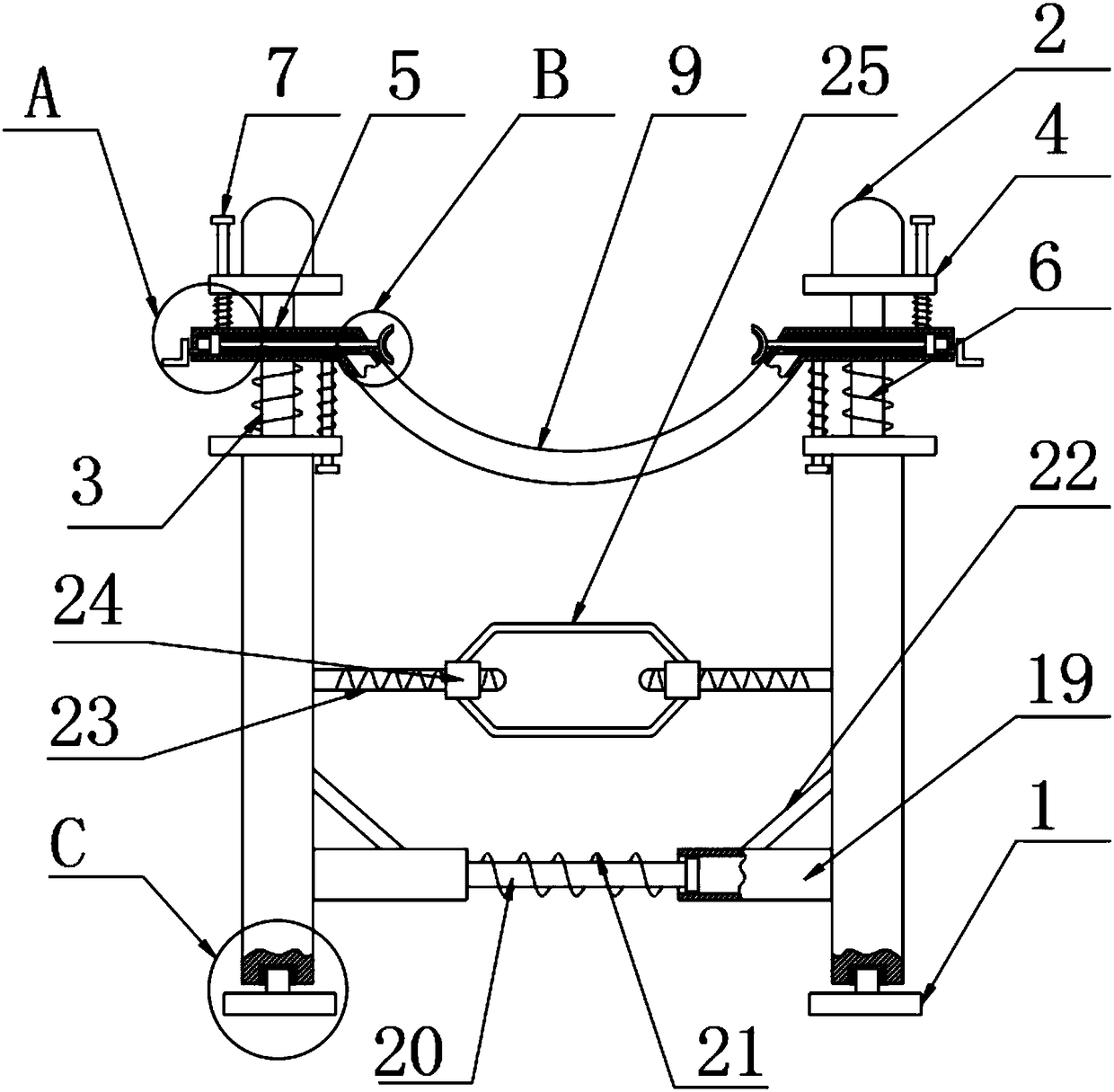

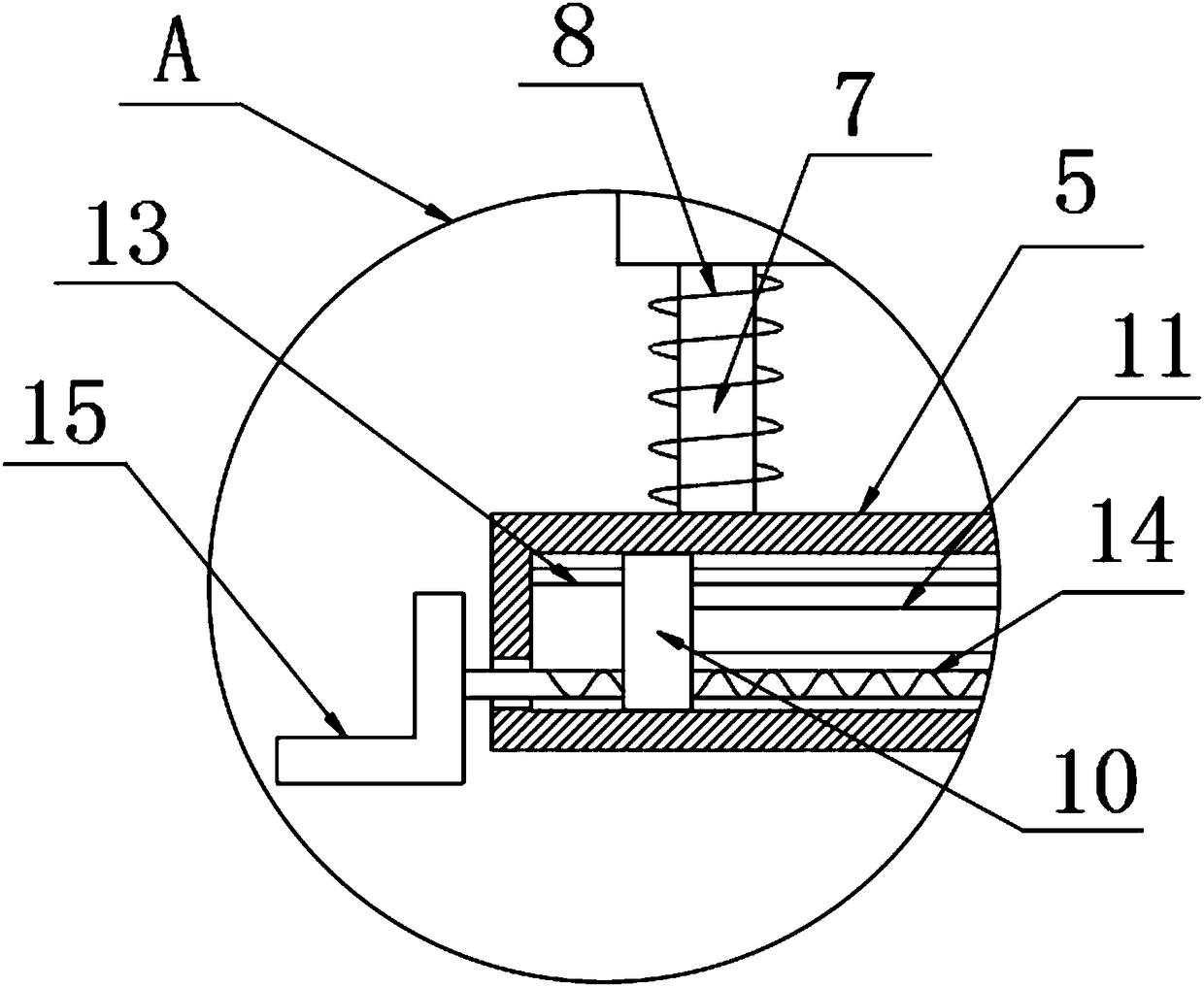

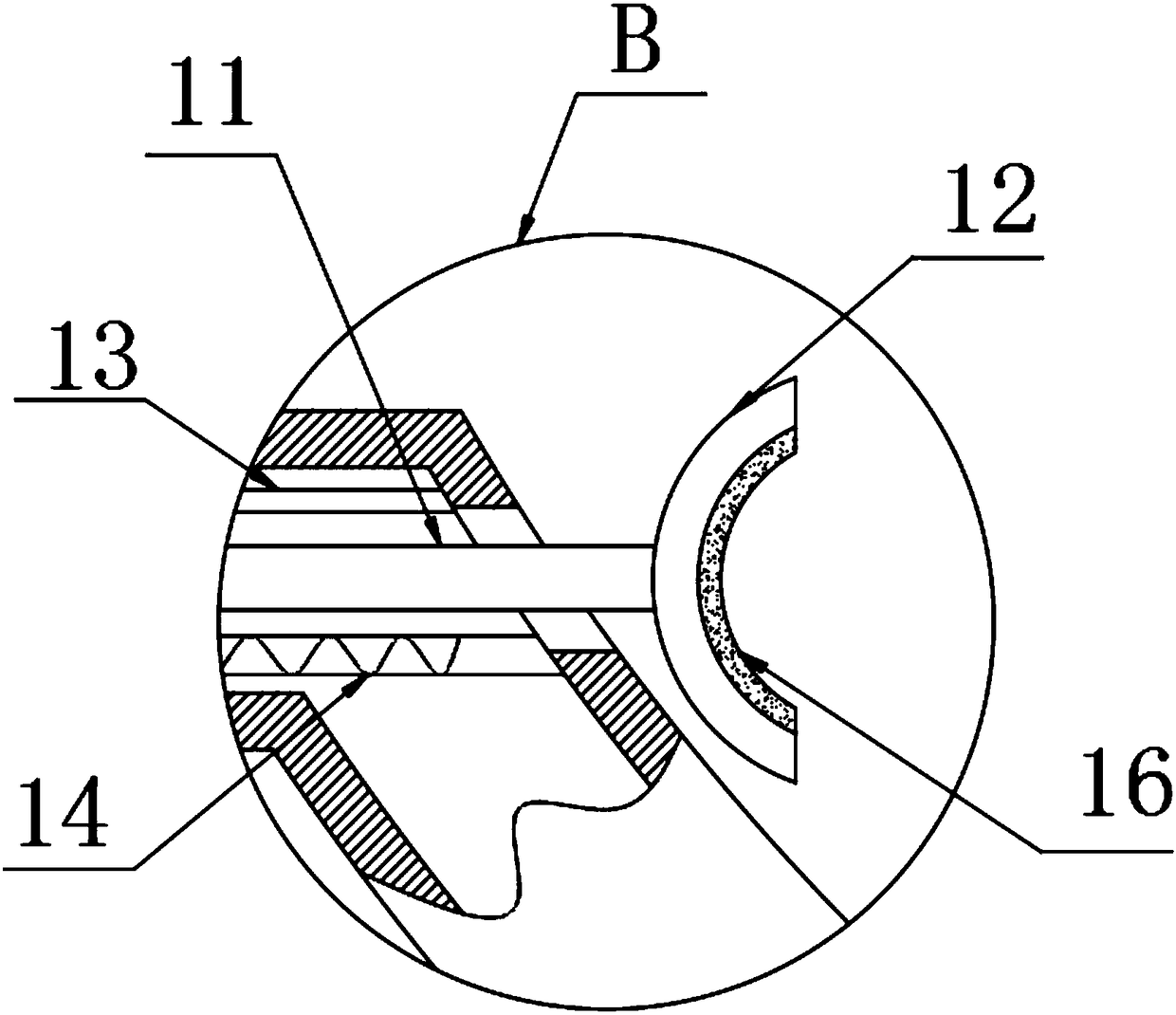

[0025] according to Figure 1-4 The shown supporting machine for pipeline repair includes a supporting base 1, a supporting leg 2 is arranged on the top of the supporting base 1, and a supporting column 3 is fixedly connected between the two ends of the supporting leg 2, and the two ends of the supporting column 3 are Both ends are fixedly connected with the limit disk 4, and the position limit disk 4 is provided to help limit the position of the sliding sleeve 5 and prevent the sliding sleeve 5 from falling off. The column 3 is located at the bottom of the sliding sleeve 5 and is slidably sleeved with a first spring 6. The top of one end of the sliding sleeve 5 and the bottom of the other end are fixedly connected with a T-shaped rod 7, and one end of the T-shaped rod 7 penetrates the limiting disc 4. The surface of the T-shaped bar 7 is slidingly sleeved with a second spring 8, and a support belt 9 is connected between the two sliding sleeves 5. The inside of the sliding sle...

Embodiment 2

[0028] One side of the elastic pressure plate 12 is provided with an anti-skid pad 16, by providing the anti-skid pad 16, the frictional force between the elastic pressure plate 12 and the pipeline is increased to prevent the pipeline from rotating. Rotationally connected, the first screw rod 14 is engaged with the first slider 10;

[0029] The bottom of the supporting leg 2 is provided with a universal bearing 17, the inner ring of the universal bearing 17 is fixedly connected with a supporting shaft 18, and one end of the supporting shaft 18 is fixedly connected with the supporting base 1, and by being provided with the universal bearing 17, It is beneficial to change the angle between the support base 1 and the support leg 2, so that the support base 1 can change the support according to the ground conditions;

[0030] A telescopic rod 19 is fixedly connected between the two supporting legs 2, and a sliding rod 20 is movably inserted between the two ends of the telescopic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com