A wastewater stirring device for reducing industrial sewage discharge

A stirring device and industrial sewage technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc. It can solve problems such as slowness, inability to achieve sufficient reaction, influence on the effect of stirring wastewater and reaction time, etc. , to achieve the effect of speeding up the reaction time and improving the speed of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

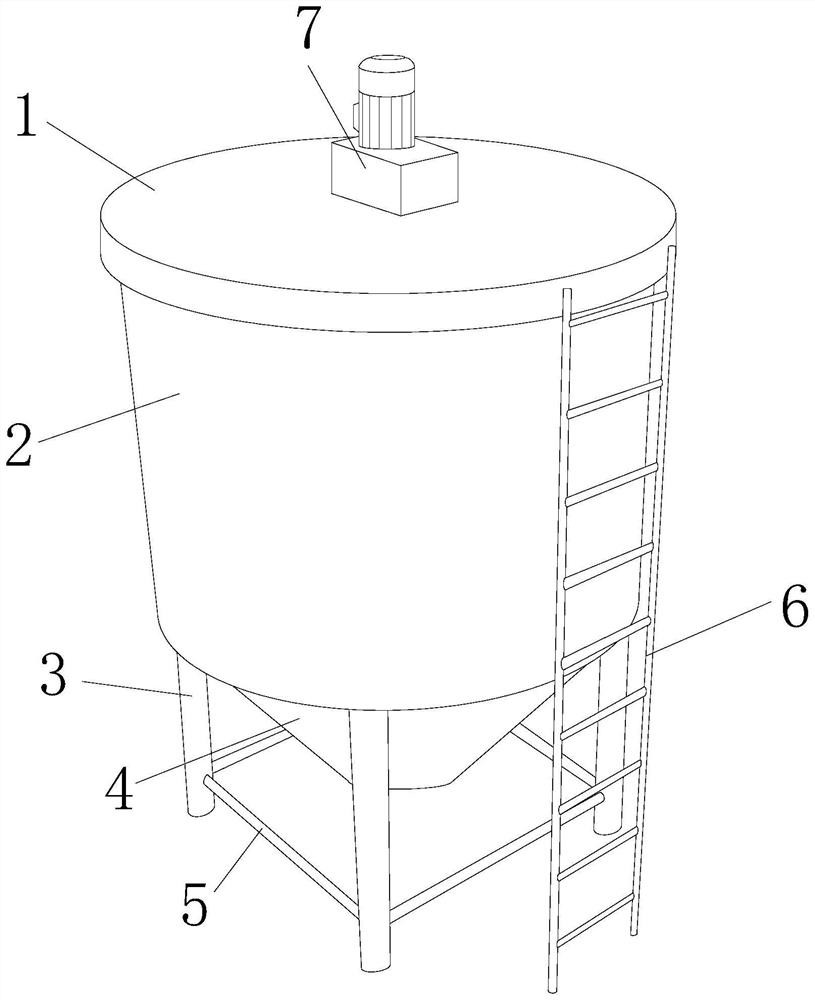

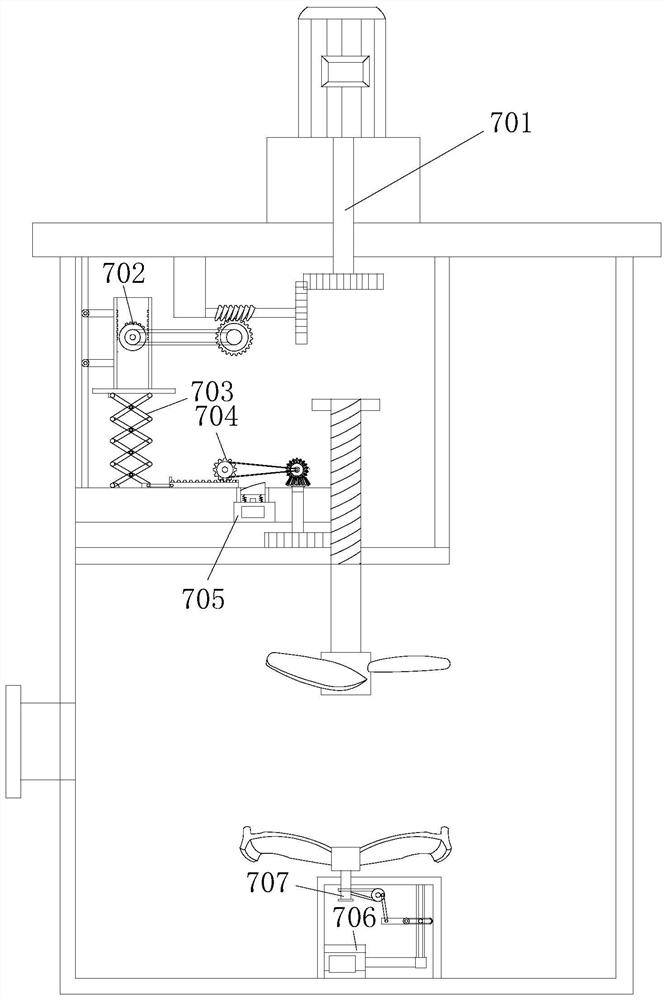

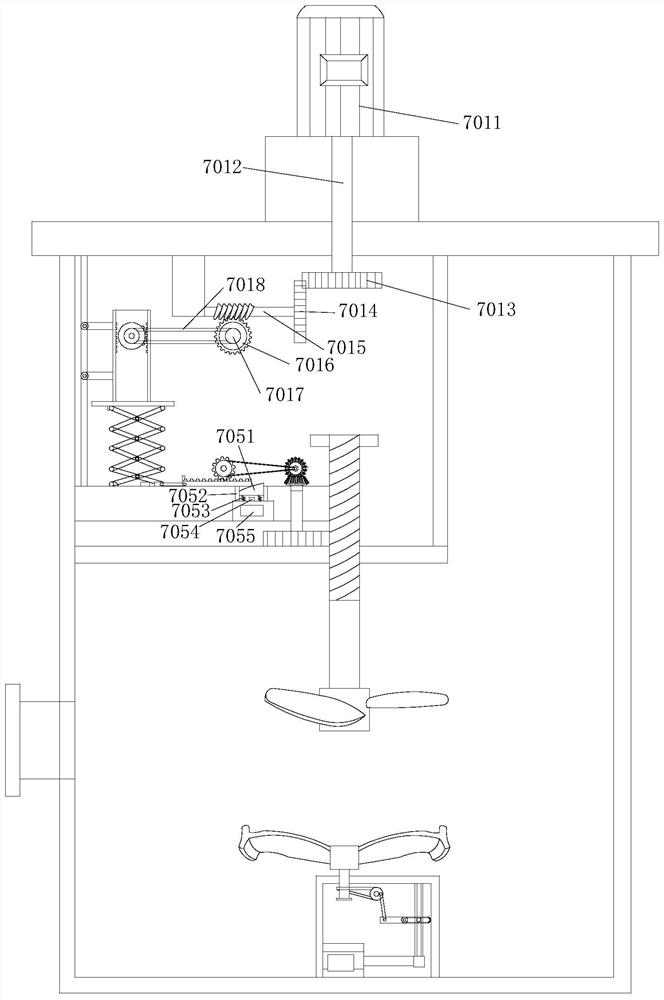

[0025] see Figure 1-Figure 6 , the present invention provides a technical scheme of a wastewater stirring device for reducing industrial sewage discharge: a wastewater stirring device for reducing industrial sewage discharge, the structure of which includes a tank cover 1, a tank shell 2, a support column 3, a wastewater Processing outlet 4, fixed frame 5, ladder frame 6, accelerated stirring device 7, the upper surface of described box body cover 1 is provided with accelerated stirring device 7 and both are installed together by the mode of embedding simultaneously, described box body cover 1 is attached to the upper surface of the tank shell 2, the outer surface of the box cover 1 and the outer surface of the ladder frame 6 are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com