Construction method of photocatalyst

A construction method and photocatalyst technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of photocatalyst material reduction, photocatalyst film layer shedding, and more PM2.5, etc., to achieve deep penetration , good atomization effect, uniform solid suspension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This technical verification uses a model LDR0009-0.7 electric heating steam generator (the heating device of this equipment is composed of two parts, the first part generates saturated steam, and the second part of the superheated steam heating tube is turned on when superheated steam is needed; therefore, the same equipment can be Generating saturated steam and superheated steam), the steam equipment is strictly operated in accordance with the operation; the temperature of superheated steam can be adjusted from 171 degrees to 410 degrees, and the pressure can be adjusted from 0 kg to 7 kg; the temperature of saturated steam can be adjusted from 100 degrees to 171 degree, pressure adjustable range from 0 kg to 7 kg. Standardize the operation to ensure safety.

[0038] The construction method of photocatalyst of the present invention comprises the steps:

[0039] (1) Cleaning of the construction surface

[0040] It takes about 1 hour to raise the temperature and pressu...

Embodiment 2

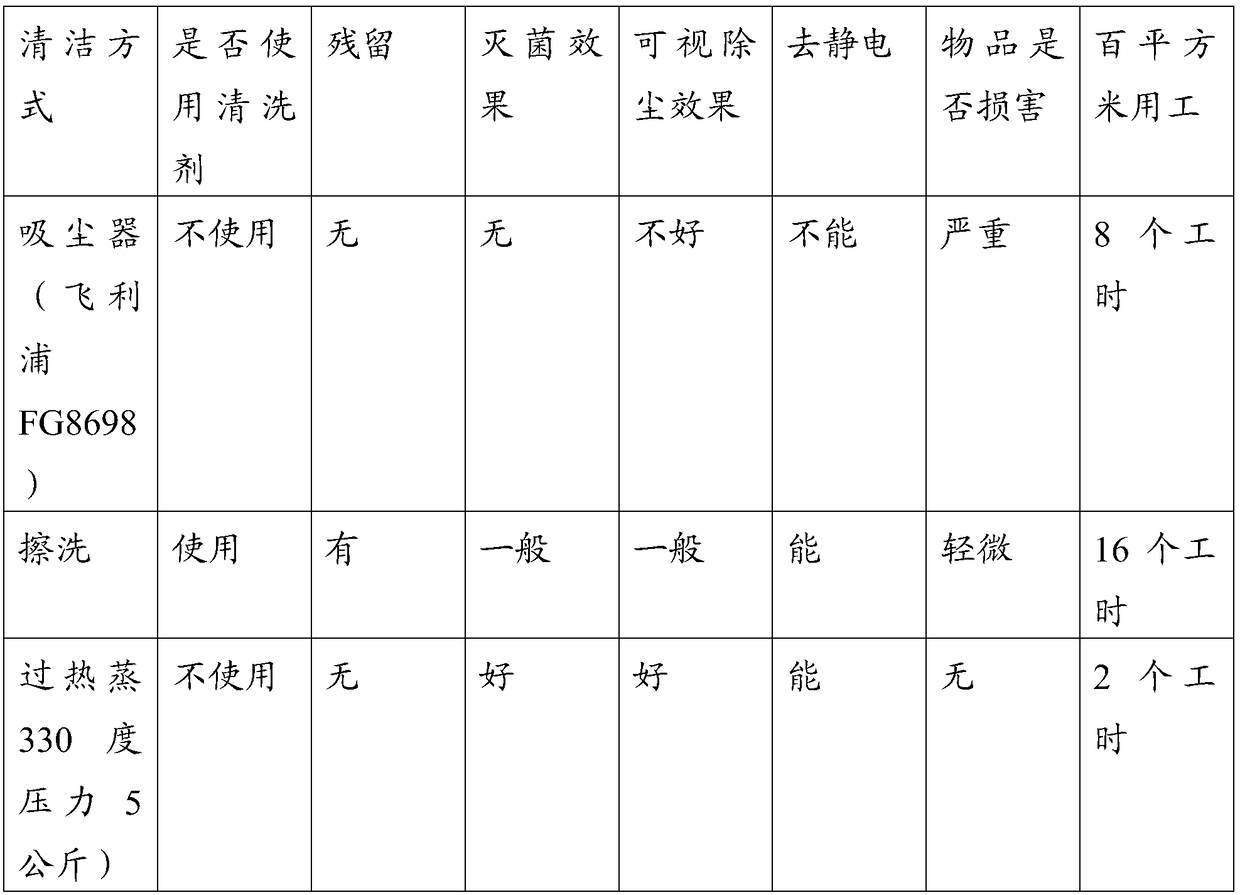

[0045] In the research and development process, once tried to adopt different cleaning methods, the results are as follows, the rest of the conditions are the same as in Example 1. The results are shown in the table below:

[0046]

Embodiment 3

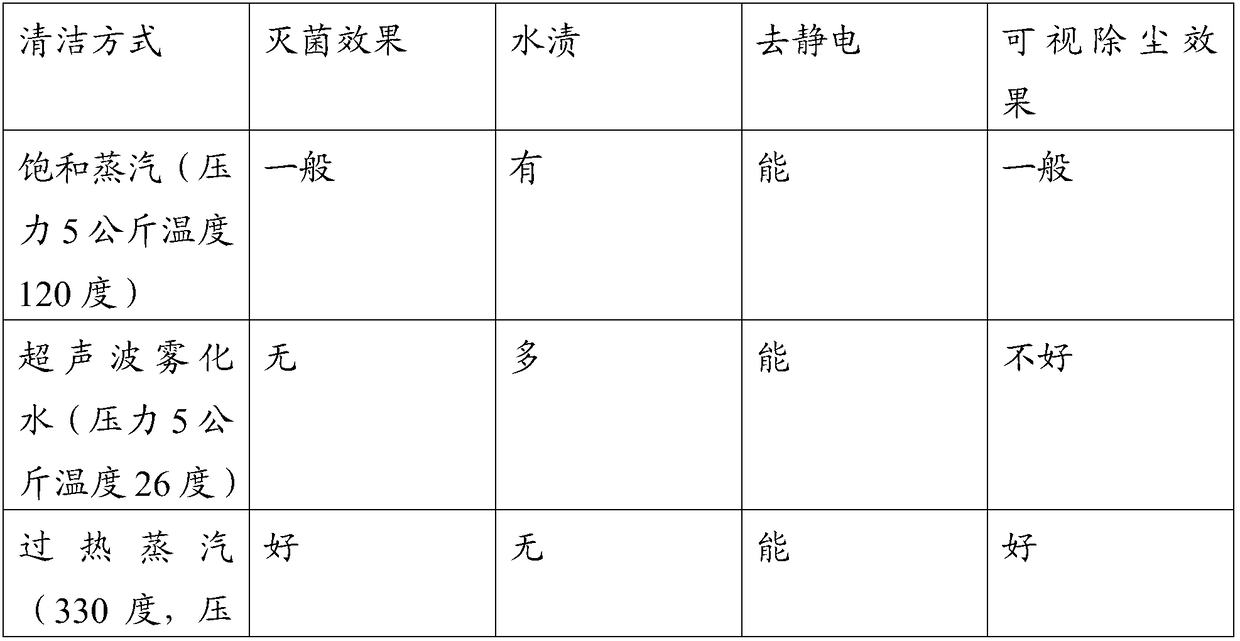

[0048] In the process of research and development, different cleaning methods have been tried, and the remaining conditions are the same as in Example 1. The results are shown in the following table:

[0049]

[0050]

[0051] Conclusion: superheated steam has better cleaning effect, good static electricity removal effect, no material damage at all, no cleaning fluid at all, no residue in cleaning, no cleaning dead angle, thorough cleaning of floating dust, convenient construction, time-saving and efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com