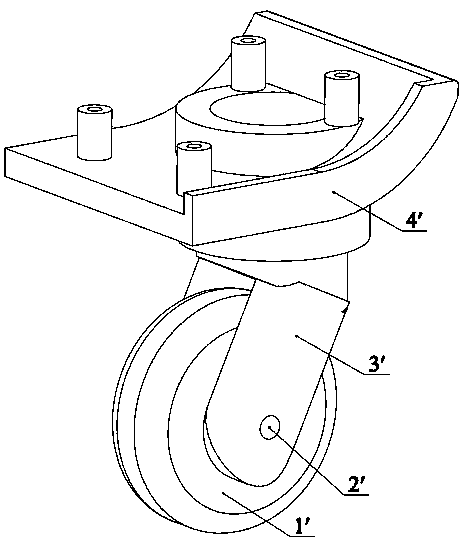

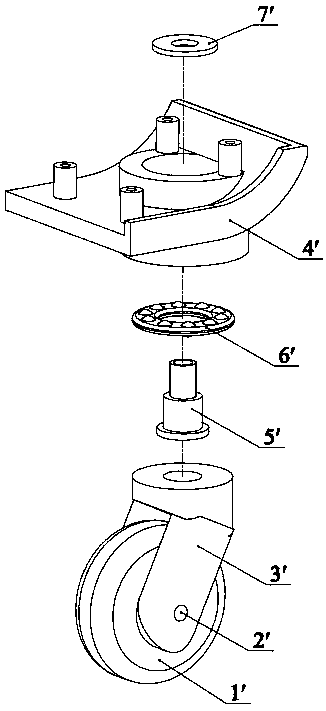

Full-automatic assembly equipment for universal wheel of bags and suitcases

A technology for assembling equipment and universal wheels, which can be used in assembly machines, metal processing equipment, household components, etc., and can solve the problems of high labor intensity and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

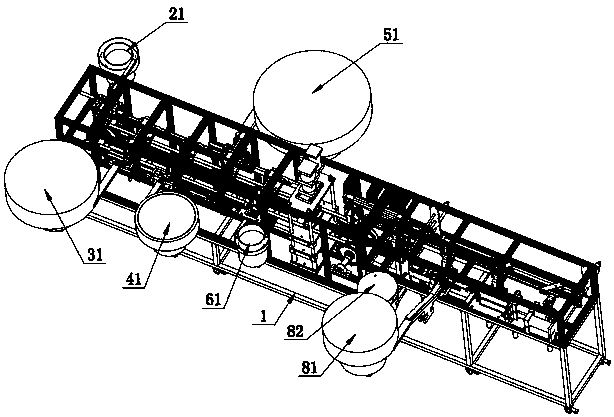

[0049] Such as Figure 3-16 Shown is a fully automatic assembly equipment for universal wheels of luggage, including a body 1, the body 1 is provided with a wheel base rivet into the station 2, a bracket into the station 3, and a bearing into the station 4 , the bracket is put into the station 5, the gasket is put into the station 6, the wheel base rivet riveting station 7, the roller assembly station 8, the synchronous conveyor belt 9 and the conveyor belt driving mechanism 10 for driving the synchronous conveyor belt 9 to transmit, and The wheel seat rivet is placed at station 2, the bracket is placed at station 3, the bearing is placed at station 4, the bracket is placed at station 5, the gasket is placed at station 6, and the wheel seat rivet riveting station 7 is synchronized The transmission direction of the conveyor belt 9 is arranged sequentially, and the synchronous conveyor belt 9 is fixedly equipped with the rivet into the station 2, the bracket into the station 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com