Multi-station rotary type golf ball supporting clamp

A golf ball, rotary technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of excessive grinding, unground side of the ball holder, unable to meet the processing requirements, etc., and achieve the effect of reducing friction and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

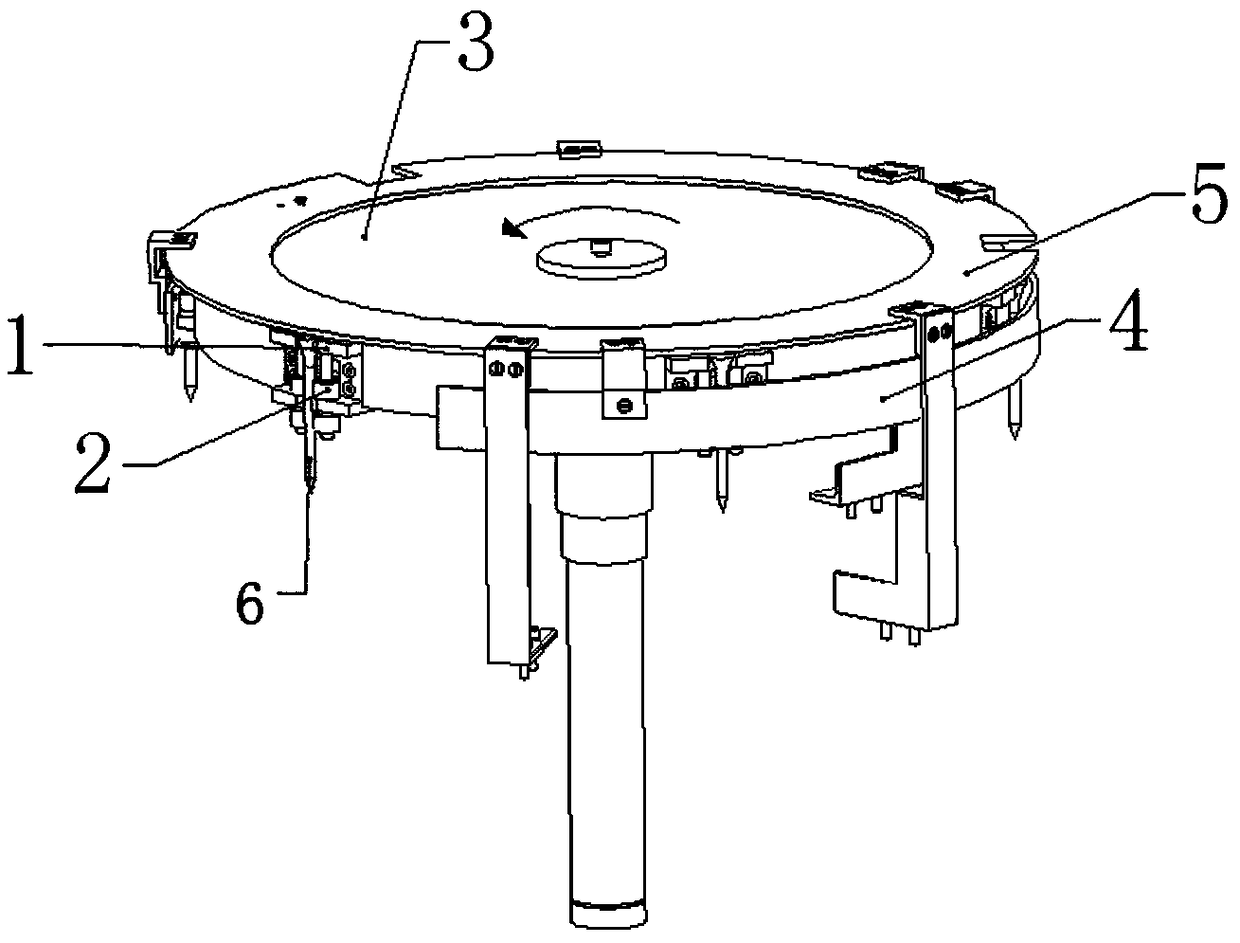

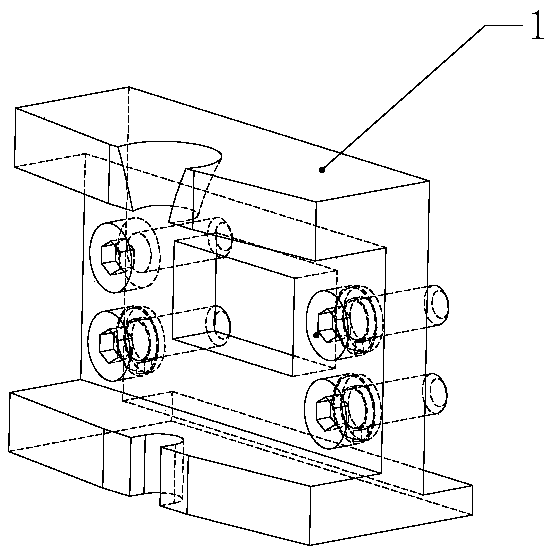

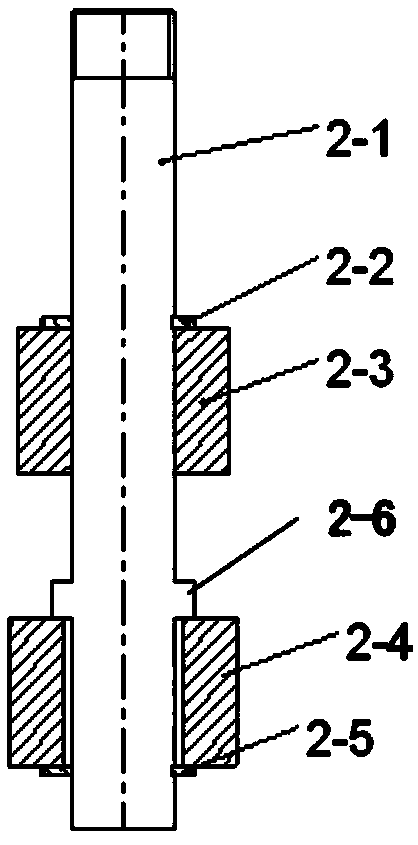

[0014] A multi-station rotary golf holder fixture, including a working disc 3 and a fixed fixture die base 1, a plurality of fixed fixture die bases 1 are evenly spaced and fixed on the side of the working disc 3, this embodiment also includes Two self-centering mechanisms 2, the two self-centering mechanisms 2 are symmetrically fixed on the die base 1 of the fixing fixture, the self-centering mechanism 2 includes a shaft, two elastic retaining rings and two bushings, the shaft The lower part of 2-1 has a shaft shoulder 2-6, the upper end of the shaft is threaded, the upper end of the shaft passes through the hole at the bottom of the die base 1 of the fixing fixture, and the hole thread corresponding to the upper part of the die base 1 of the fixing fixture connection, the first shaft sleeve 2-3 is sleeved on the shaft 2-1 and is located on the upper part of the shaft shoulder 2-6, the activity of the first shaft sleeve 2-3 is controlled by the first elastic ring 2-2 and the d...

Embodiment 2

[0016] as attached figure 1 As shown, a multi-station rotary golf tee fixture includes a working disc 3, a hoarding mechanism 4, a cover mechanism 5 and a fixing fixture die base 1, and a plurality of fixing fixture die bases 1 are evenly fixed On the side of the working disc 3, the self-centering mechanism 2 is fixed on the die base 1 of the fixture, the hoarding mechanism 4 is distributed on the edge of the working disc 3, and there is a certain distance between the working disc 3, and the hoarding mechanism 4 is fixed On the frame, the cover plate mechanism 5 is located directly above the working disk 3, and there is a certain distance between the working disk 3, and the cover plate mechanism 5 and the enclosure mechanism 4 are connected and fixed by a connecting mechanism; its characteristic is that it also includes Two self-centering mechanisms 2, as attached figure 1 , 3 , 5, two self-centering mechanisms are symmetrically fixed on the die base 1 of the fixture, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com