Underwater suction type jaw clutch device

A clutch device and claw technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of difficulty in disengagement, lack of pressure-resistant structures, and inability to directly use large-depth underwater structures, and achieve reliable clutching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and embodiments.

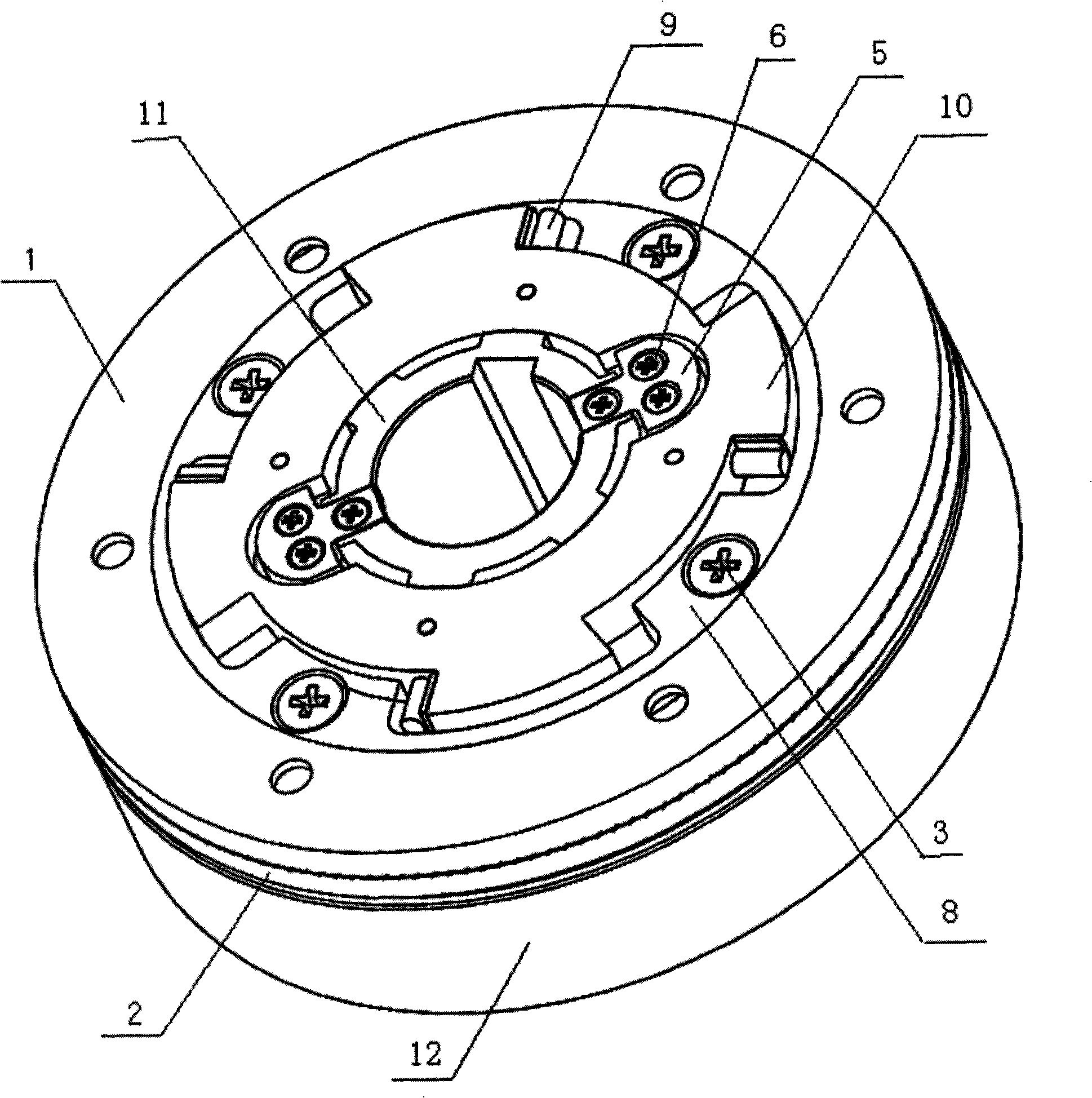

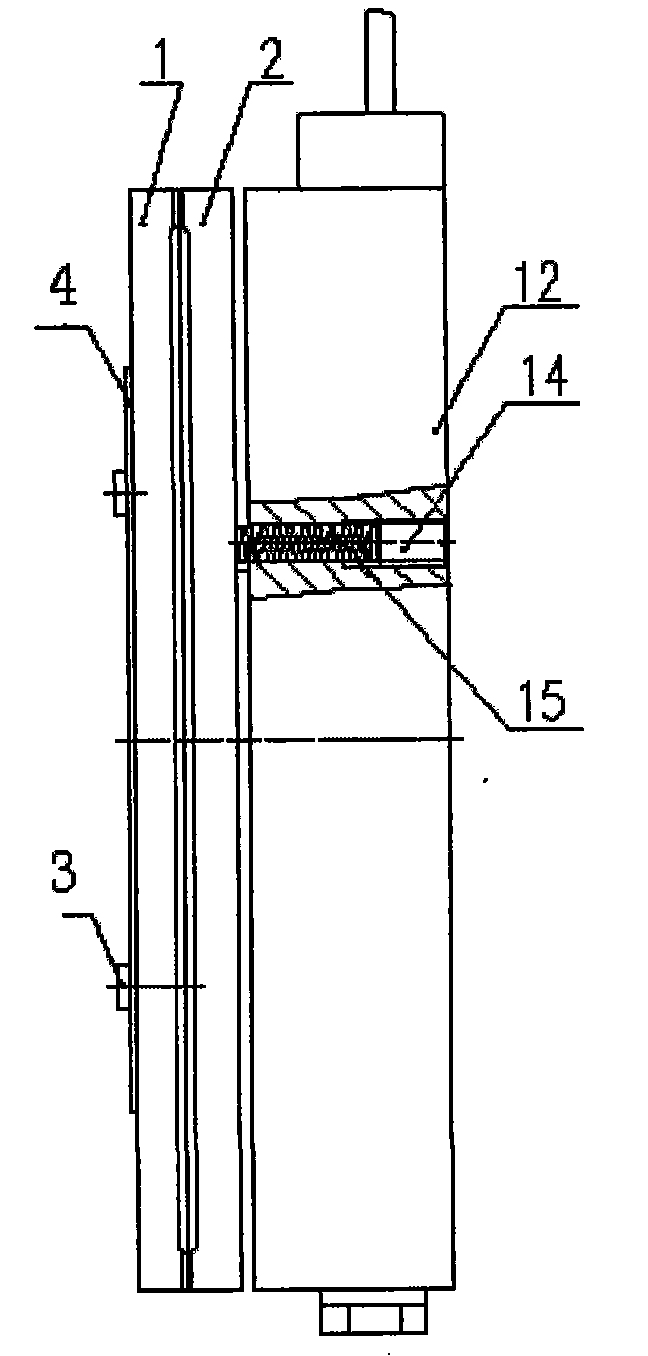

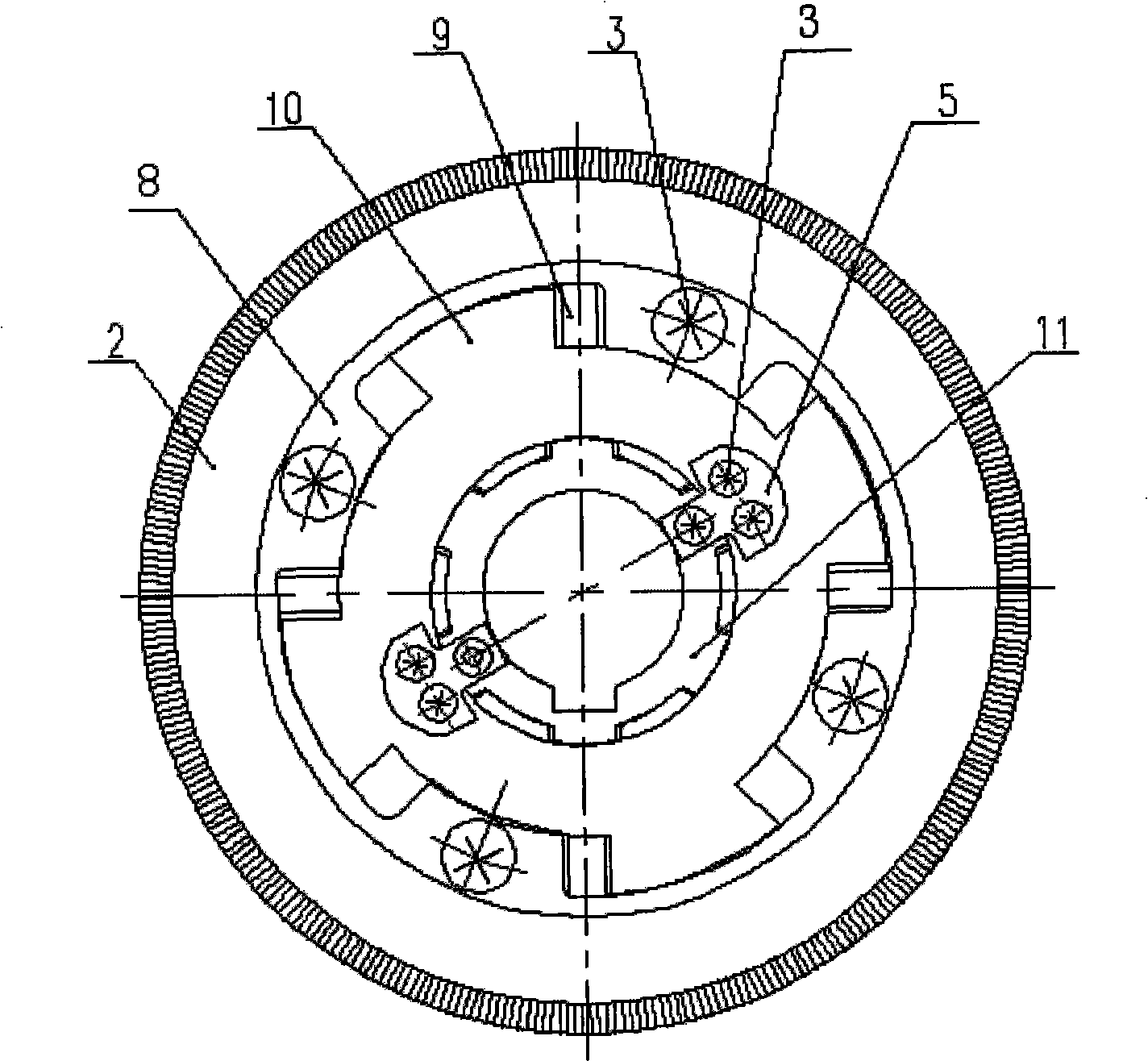

[0018] See figure 1 , figure 2 , image 3 , Figure 4 As shown, a pull-on jaw clutch device for underwater use includes a tooth ring 1, a jaw 2, and a magnetic core 12. A threaded hole is provided on the jaw 2, and a large key piece 8 is fixed by a screw 3. On the inlay 2; the small key piece 10 is fixed to the end of the screw sleeve 11 through the pressing piece 5 with a screw 3; a roller 9 is installed in the gap between the large key piece 8 and the small key piece 10, so that the The sliding friction at the spline connection between the jaw 2 and the screw sleeve 11 is converted into rolling friction between the large key piece 8 and the small key piece 10, thereby ensuring that the jaw clutch device can achieve reliable clutching under high torque. In order to prevent the rollers from falling off from the gap, a baffle piece 4 is fixed on the outer surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com