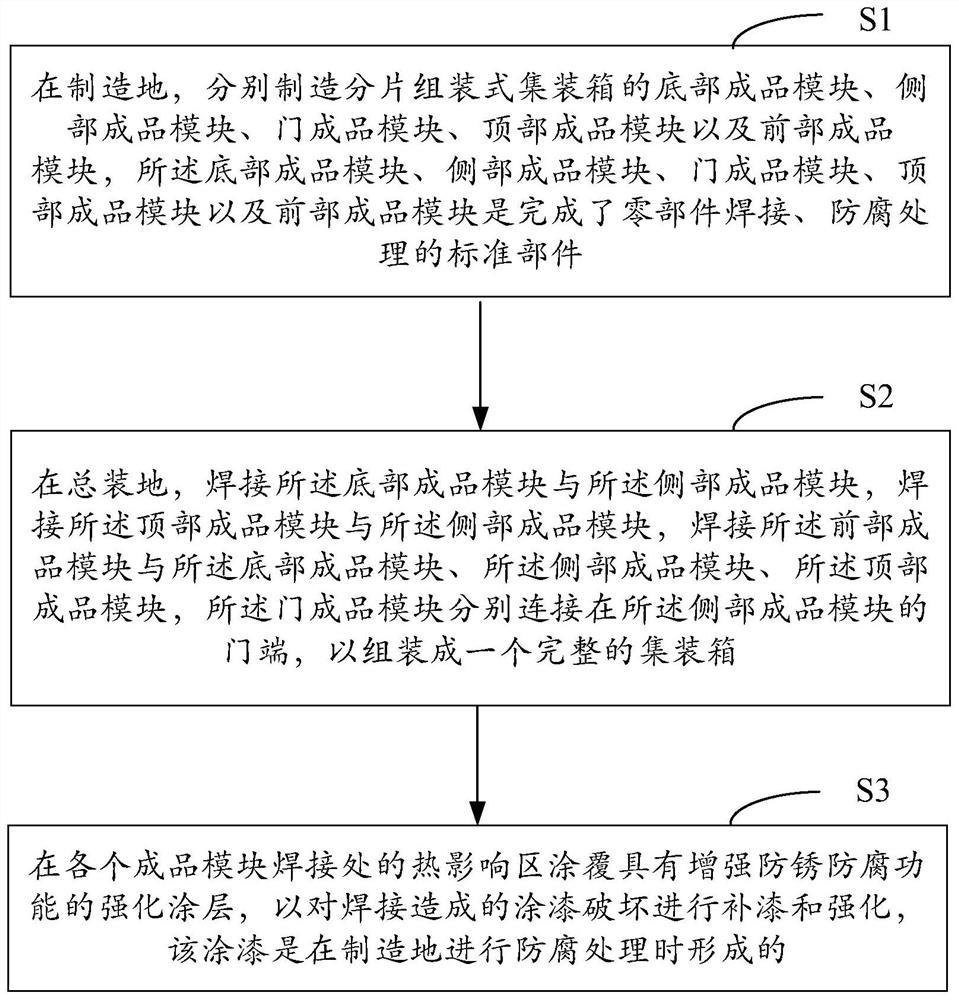

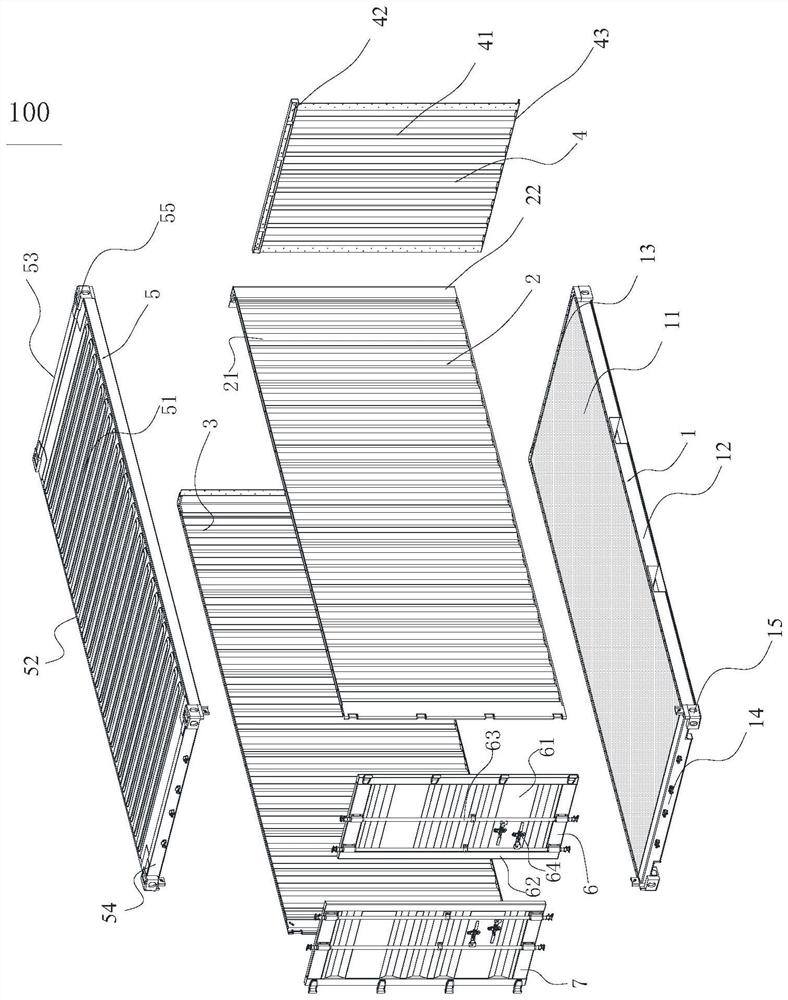

Slice-assembled container and its manufacturing method

A manufacturing process and container technology, which is applied in the field of piece-assembled container and its manufacturing process, can solve the problems of poor airtightness of the piece-assembled container, and achieve excellent anti-rust and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0028] As mentioned in the background art, in the prior art, there is a problem of poor airtightness in the sub-assembled container assembled by connectors (such as rivets, etc.). To solve this problem, the present invention proposes a The manufacturing process method, which uses welding to assemble each finished module, because the high temperature generated during the welding process is likely to cause the original anti-corrosion paint on the heat-affected zone (that is, the three-layer paint sprayed during the anti-corrosion treatment at the manufacturing site) Damaged, therefore, the present invention coats the strengthening coating with enhanced anti-rust and anti-corrosion function at the welding place. The enhanced coating has a stronger anti-rust and anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com