Convex surface forming device for cloth

A forming device, convex surface technology, applied in fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., can solve problems such as easy deformation, poor convex forming effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

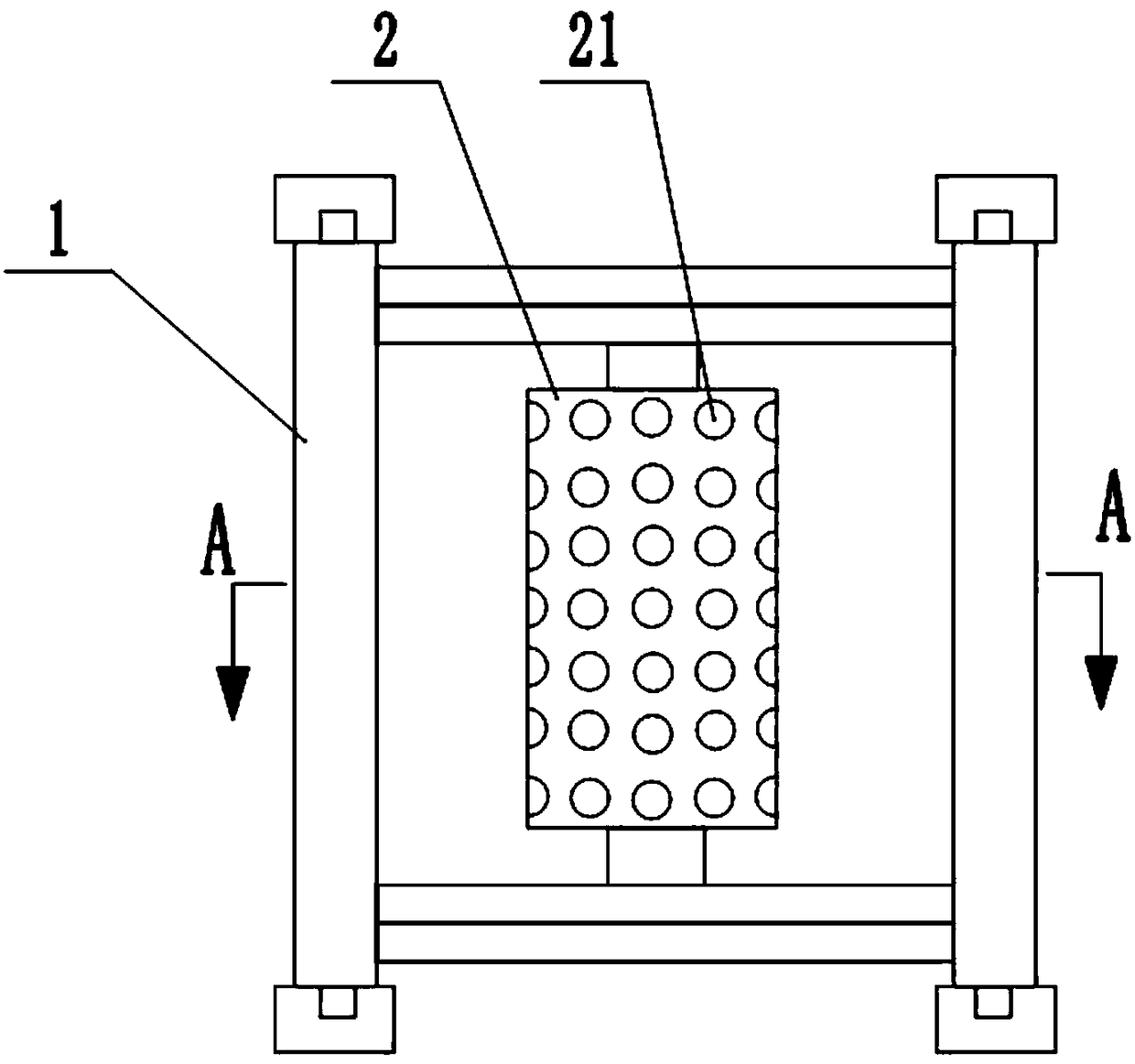

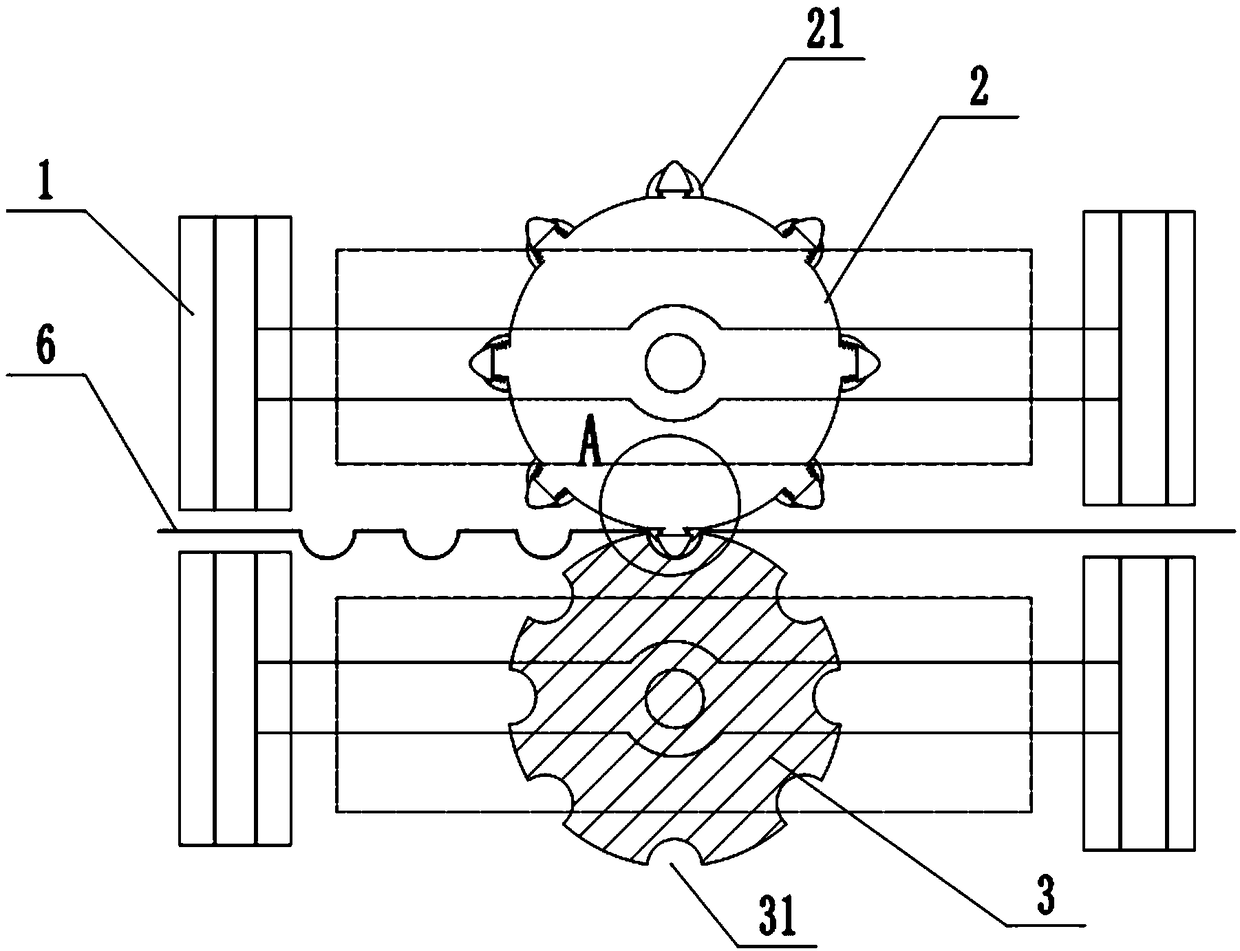

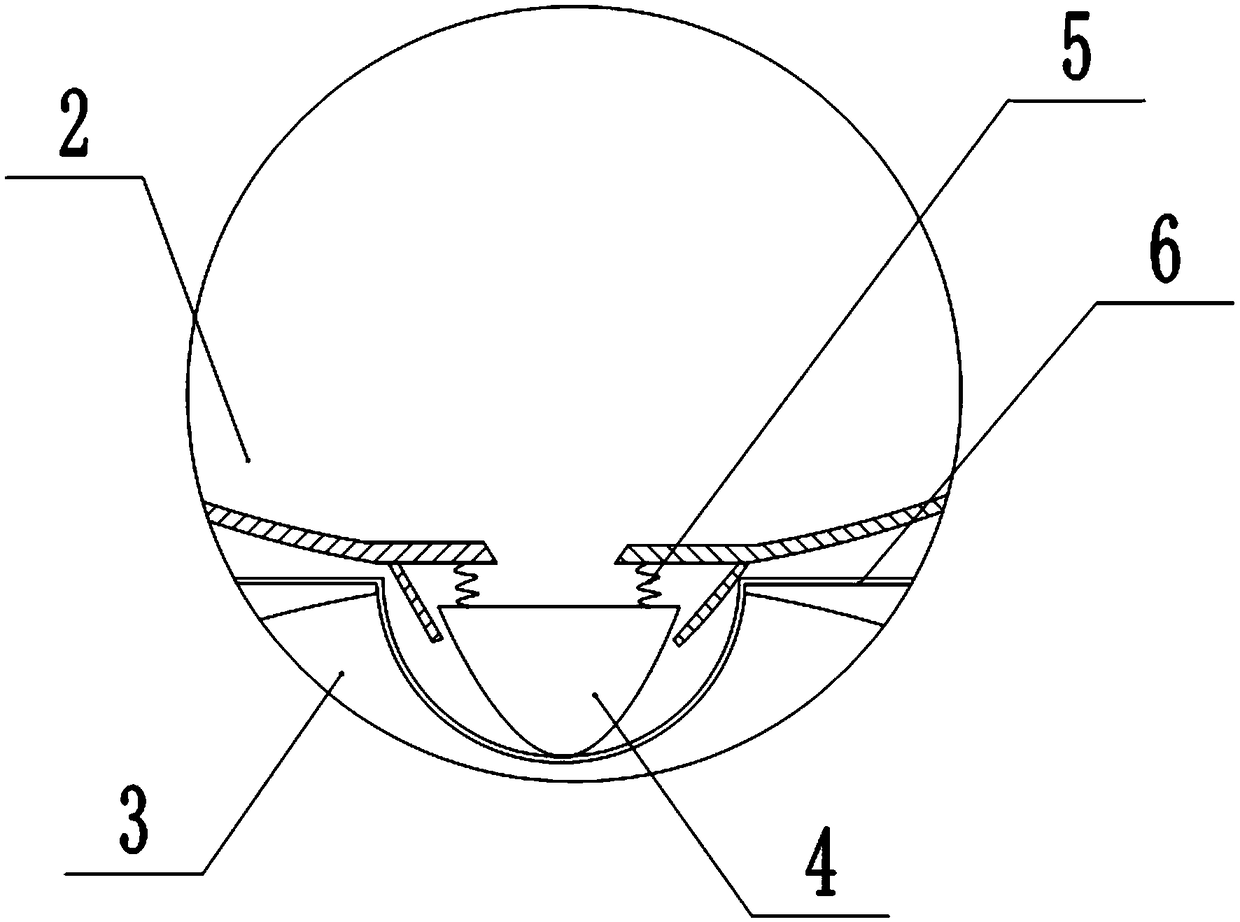

[0018] The reference signs in the drawings of the description include: frame 1, upper feed roller 2, hemispherical projection 21, lower feed roller 3, hemispherical groove 31, block 4, spring 5, cloth 6.

[0019] The embodiment is basically as attached Figures 1 to 3 Shown: a cloth convex forming device, including a frame 1, which is equipped with upper and lower corresponding upper feed rollers 2 and lower feed rollers 3, and the inner cavity of the upper feed roller 2 is filled with Melt the wax liquid, and the circumferential surface of the upper feeding roller 2 is evenly and densely covered with hemispherical protrusions 21, and the convex part of the hemispherical protrusions 21 is provided with an opening, and the opening is slidably connected with a block 4 for sealing the opening, and the block 4 Extending out of the opening, a spring 5 is connected between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com