Telegraph pole bending correction device

A technology for utility poles and utility poles, applied in the field of utility pole bending correction devices, can solve problems such as pedestrian and vehicle danger, utility pole breakage and bending, road congestion, etc., and achieve the effect of ensuring power supply and avoiding traffic congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

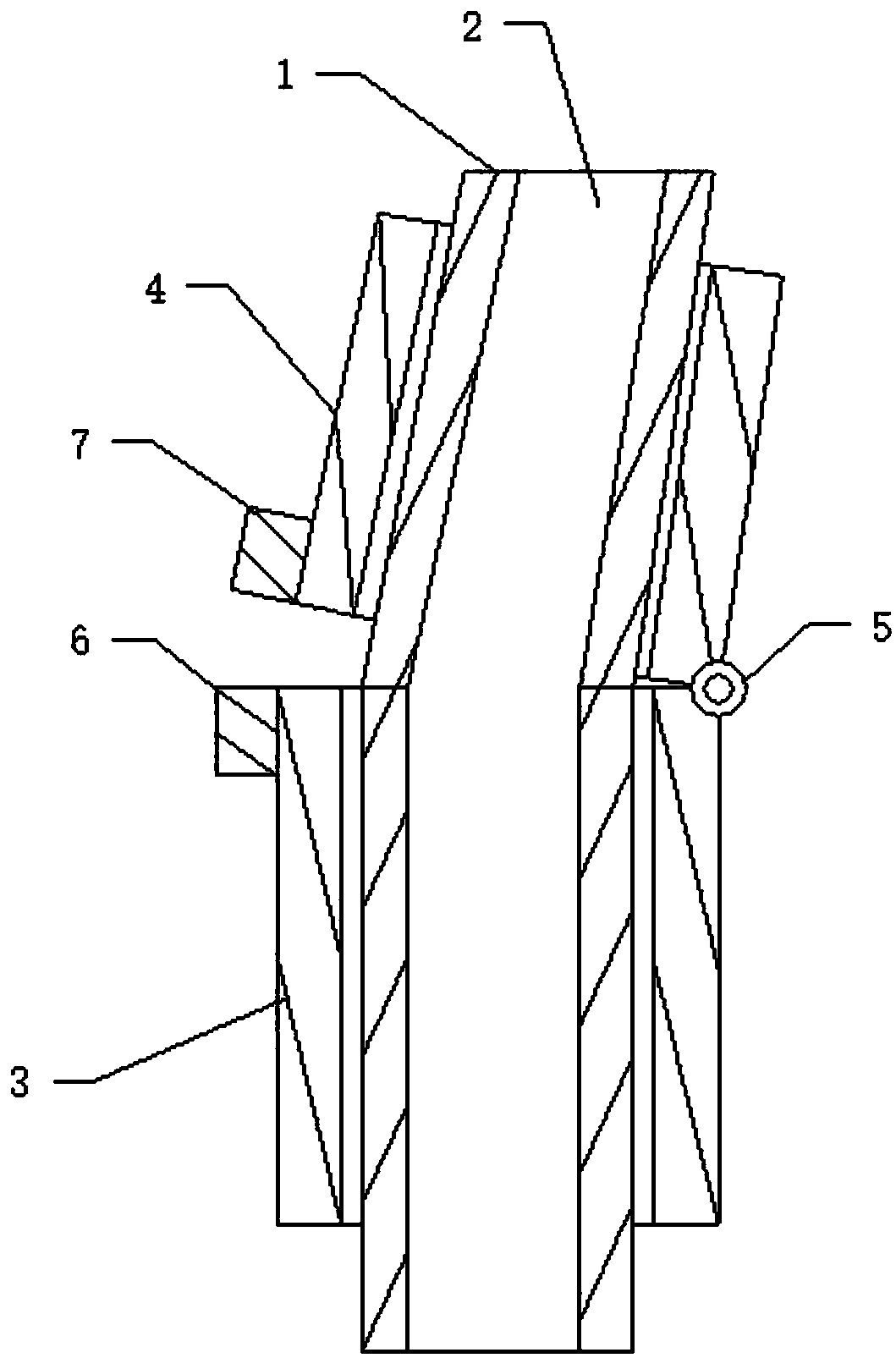

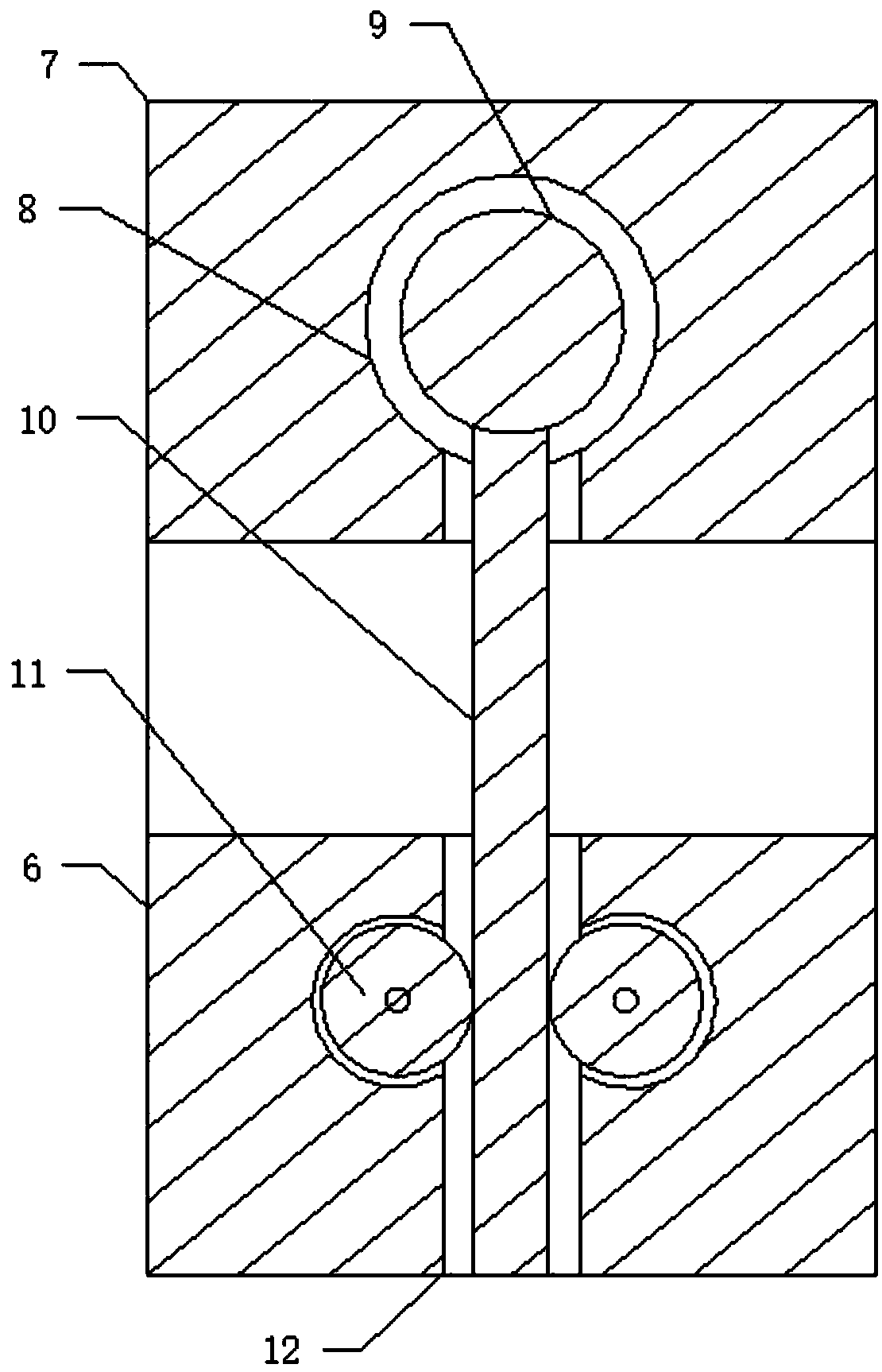

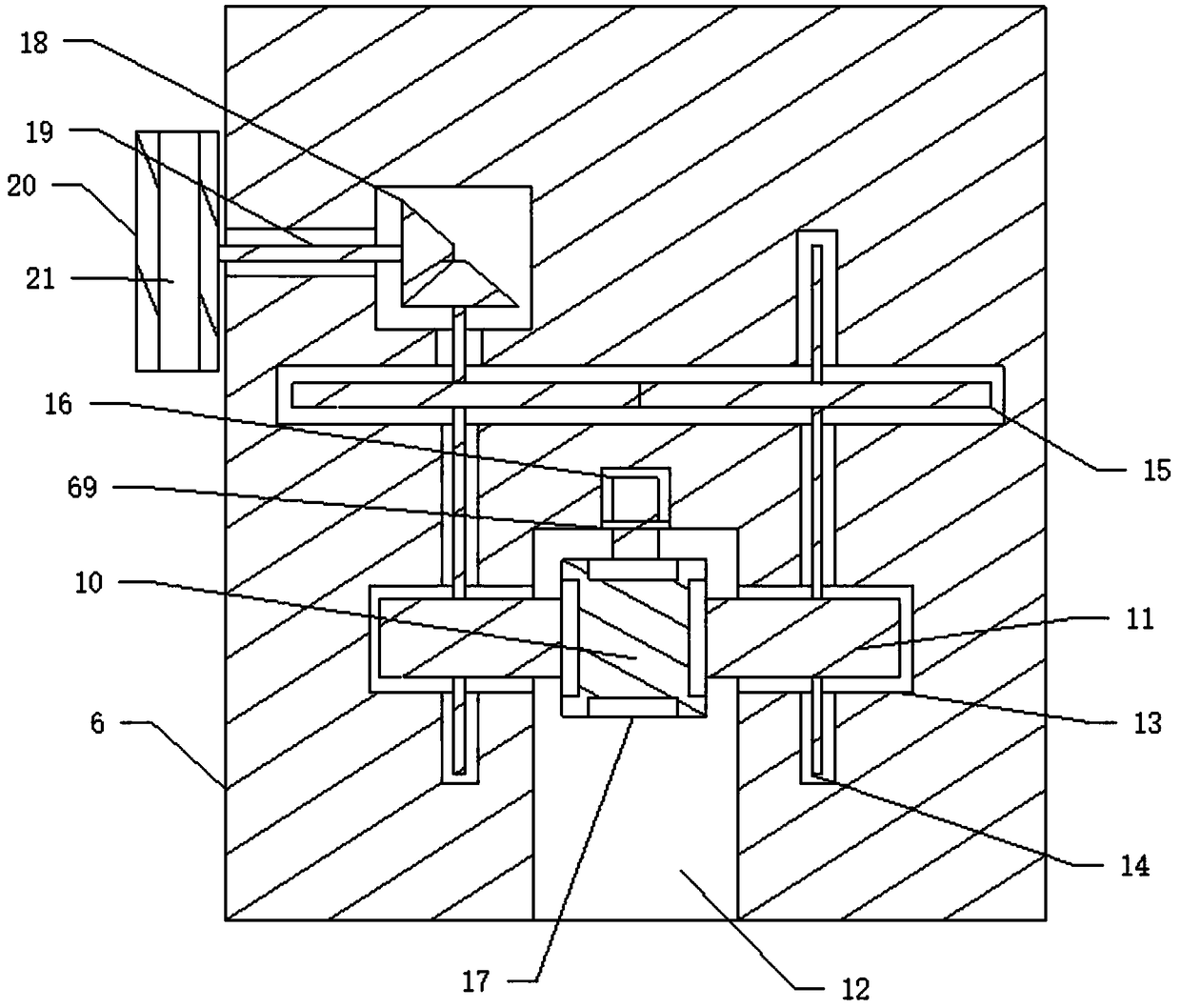

[0034] Such as Figure 1 to Figure 10 As shown, a utility pole bending correction device includes a utility pole 1, a utility pole cavity 2 is arranged inside the utility pole 1, a first sheath 3 and a The second sheath 4, the second sheath 4 rotates on the first sheath 3, the first sheath 3 and the second sheath 4 are respectively provided with a corresponding first connection Block 6 and second connecting block 7, described second connecting block 7 is provided with a swinging pull slide shaft 10, and described first connecting block 6 is provided with the first meshing wheel that drives described pull slide shaft 10 to slide 11. One side of the first connecting block 6 is provided with a rotating second rotating shaft 19, the second rotating shaft 19 drives the first meshing wheel 11 to rotate, and the second rotating shaft 19 is provided with a rotating sleeve tube 20, a first sliding hole 21 is provided on the rotating sleeve 20, and a snap-in sliding shaft 24 that slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com