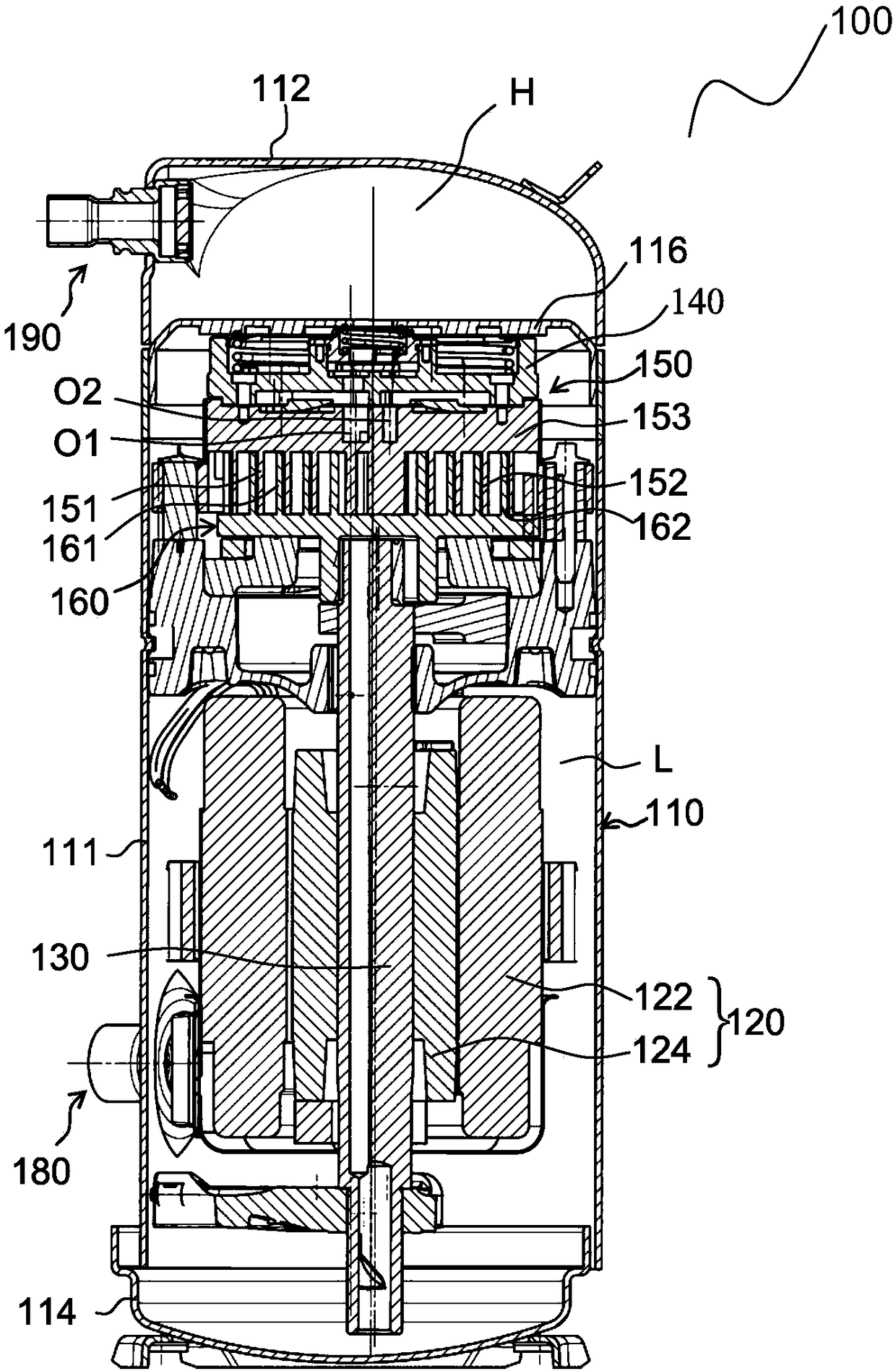

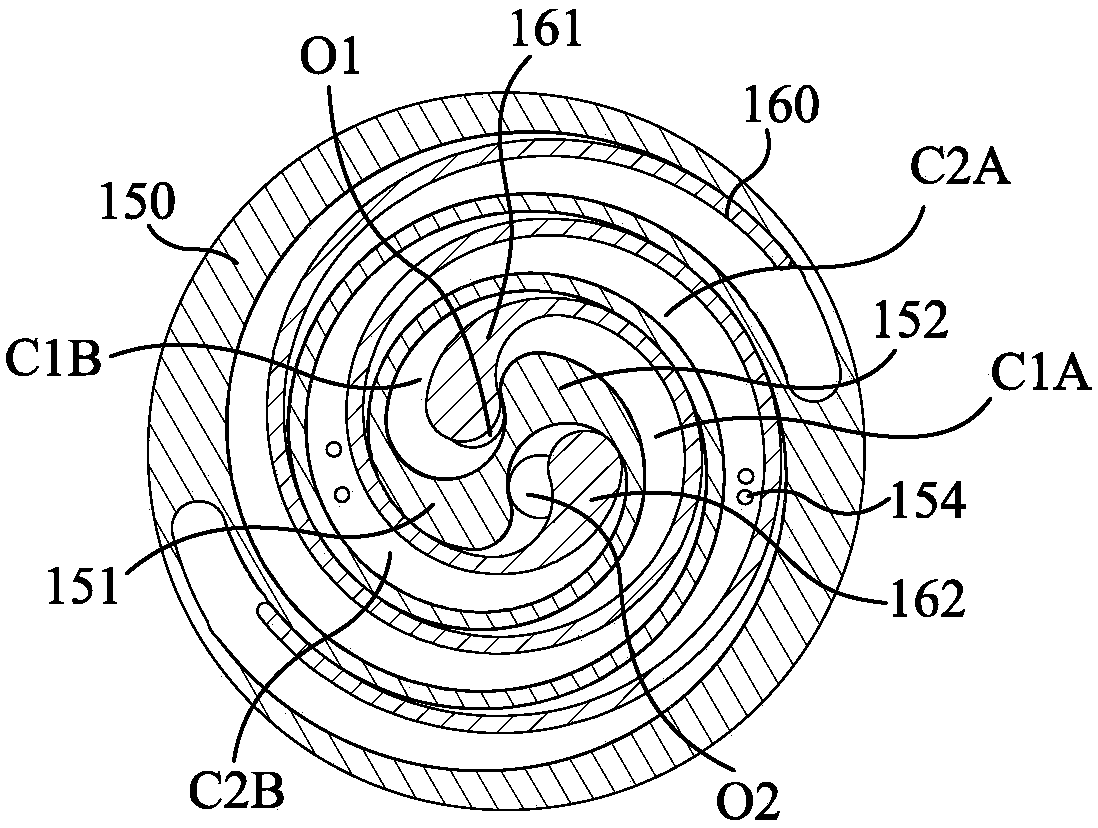

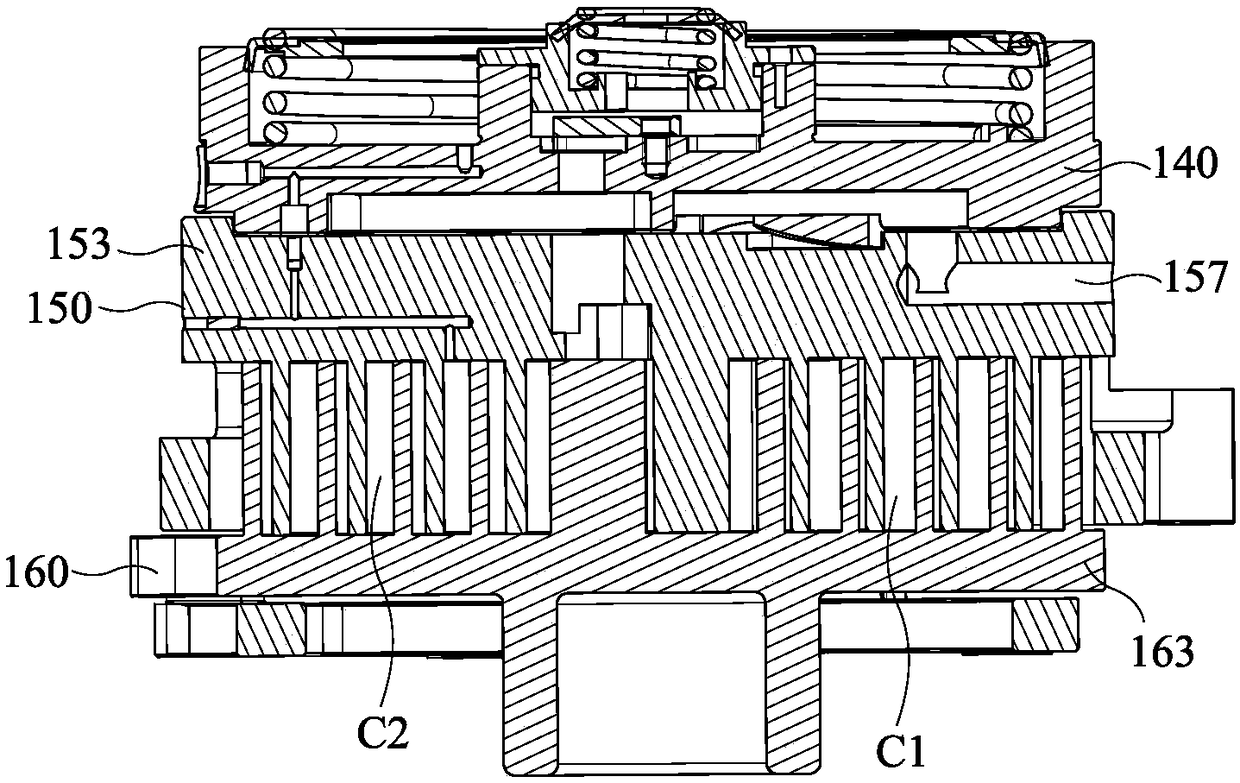

Scroll compressor and control method thereof

A technology of a scroll compressor and a control method, which is applied in the field of compressors, and can solve problems such as motors being unable to rotate, unable to start normally, hindering the lubrication of friction pairs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage. The same reference numerals are used to denote the same components in the respective drawings, and thus the configurations of the same components will not be described repeatedly.

[0039] Firstly, the basic technical idea of the present invention is briefly described. The inventors have noticed that the main cause of excessive friction at each friction pair in the compressor at the initial stage of startup is the time lag between the establishment of load in the compressor and the effective lubrication provided by the lubrication system, that is, the establishment of effective lubrication in the compressor relative to the load There is a lag in build. For this reason, the inventors propose a solution to build up system pressure after establishing effective lubrication in the system pressure to avoid excessive friction at the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com