Novel opening and closing type oil filling valve

A technology of opening and closing, oil-filled valves, applied in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as loss of sealing effect, trouble, thread failure, etc., to avoid thread jamming, simple and convenient operation , to avoid the effect of fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

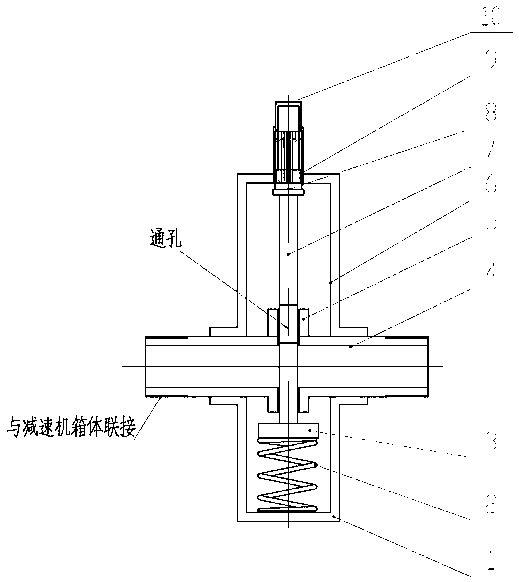

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] The new open-close oil filling valve includes a spring box 1, a spring 2, a spring base 3, an oil channel 4, a guide plate 5, a control box 6, an oil baffle 7, a telescopic rod 8, a cartridge 9 and a pressing set of 10;

[0020] The open-close oil filling valve is divided into upper and lower parts through the oil channel 4, the upper part is the control box 6, and the lower part is the spring box 1;

[0021] The spring box 1 is arranged at the bottom end of the open-close type oil filling valve, and a spring 2 is arranged inside it, and a telescopic rod 8 is arranged in the control box, and the telescopic rod 8 passes through the spring base 3 and the spring in the spring box 1 2 connected;

[0022] The telescoping rod 8 is provided with a cartridge 9 on the part extending out of the control box, the top of the protruding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com