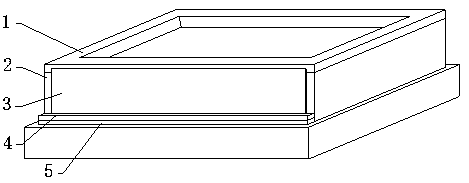

Filter screen for industrial circulating water

A technology for industrial circulating water and filter screens, which is applied in the direction of filtration separation, filtration treatment, fixed filter element filters, etc., which can solve the problems of inconvenient filter removal and replacement, cleaning, and low use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

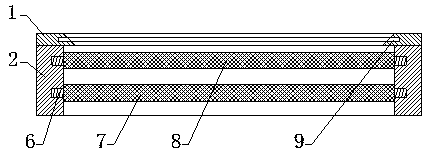

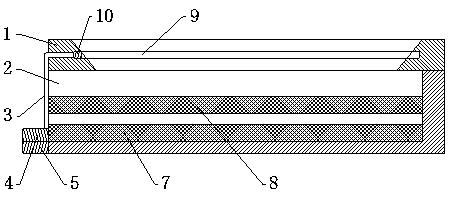

specific Embodiment approach

[0020] Specific implementation: In actual use, the user pours circulating water into the interior of the annular baffle 1, causing the circulating water to pass through filter two 8 and filter one 7 in turn, and then filter one 7 and filter two 8 are paired The impurities in the circulating water are filtered. When there are many impurities on the first filter 7 and the second filter 8, the user holds the magnet bar 4 and moves it upwards to separate the magnet bar 4 from the iron plate, and then opens the frame 2 Front side, then the user first moves the filter screen 2 8 forward, and the filter screen 2 8 moves forward to drive the sliding bar block 6 to move forward along the sliding groove, and then drives the impurities on the filter screen 2 8 to move out of the frame 2, and then The filter screen two 8 is cleaned, and then the filter screen two 8 after cleaning is reset, and the filter screen one 7 is moved forward, so that the filter screen one 7 is disassembled, replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com