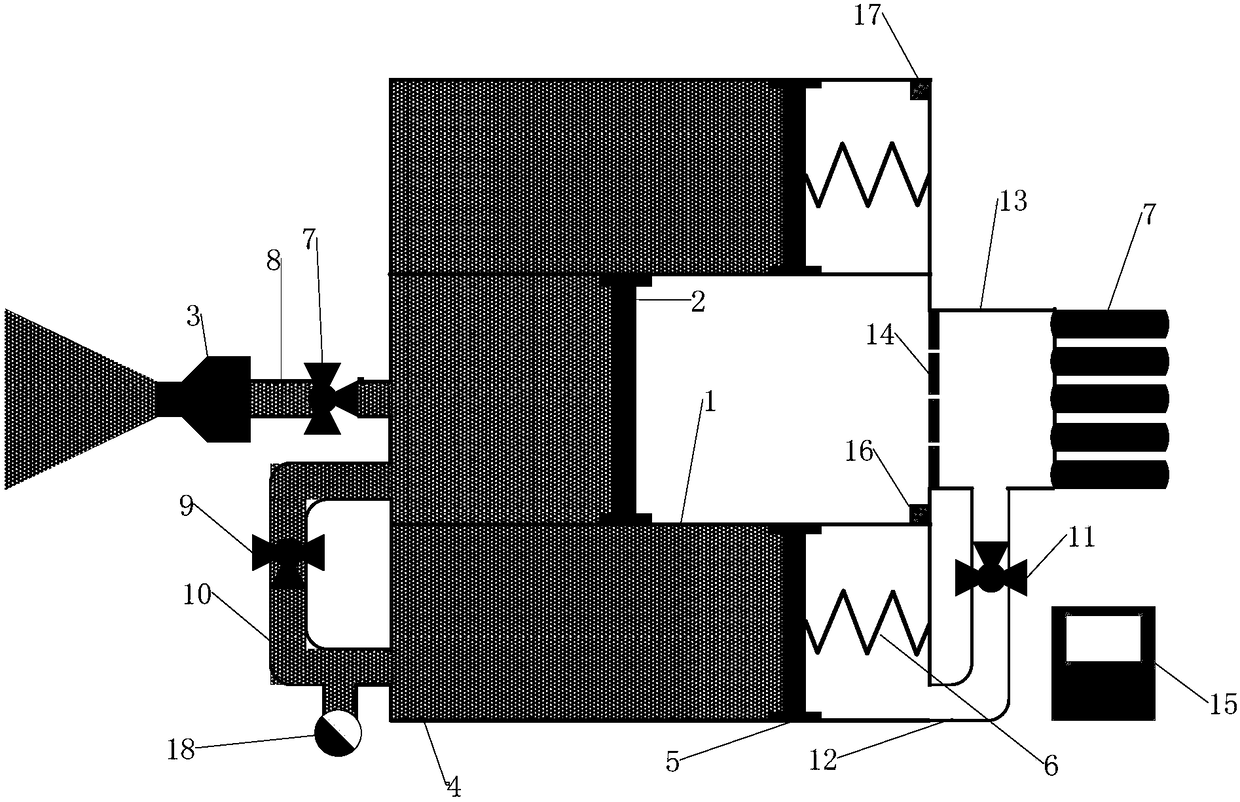

Integrated flow jetting device capable of achieving repeated jetting and flow jetting method

A jet device and multiple jet technology, applied in the field of jet, to achieve the effects of stabilizing dynamic sealing, increasing the effective use volume, and increasing the spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

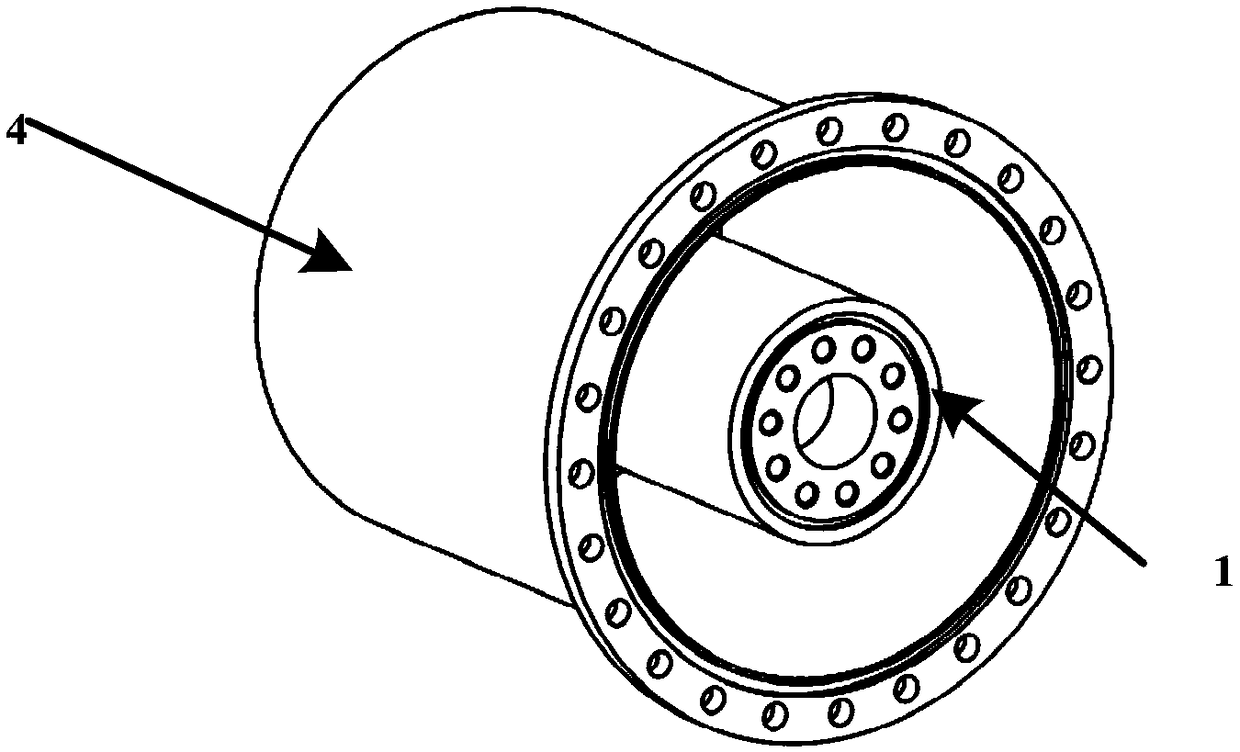

[0063] In this embodiment, the jet tank 1 and the supply tank 4 are nested structures of coaxial cylindrical shells, the diameter of the jet tank 1 is smaller than the supply tank 4, and is the inner cylindrical shell of the nested cylindrical shell, and the supply tank 5 is a nested cylindrical shell The outer cylindrical shell of the body.

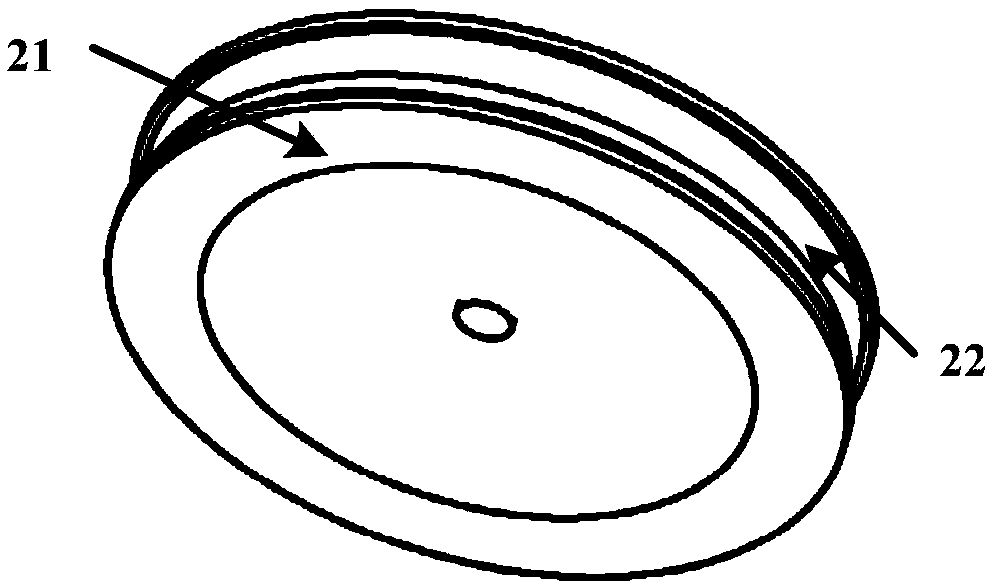

[0064]Both the jet tank piston 2 and the supply tank piston 5 are rodless moving pistons, the inner and outer walls of the jet tank 1 and the inner wall of the supply tank 4 are smooth and have no groove walls; the jet tank piston 2 includes a jet tank piston main structure 21 and a sleeve The first Y-shaped sealing ring 22 on the main body structure 21 of the jet tank piston. Dynamic sealing; the supply tank piston 5 includes a supply tank piston main body structure and a second Y-shaped sealing ring and a third Y-shaped sealing ring sleeved on the inner and outer surfaces of the supply tank piston main body structure 51, and the supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com