Automatic feeding and assembling device of coil frameworks

A coil bobbin and automatic feeding technology, which is applied to assembly machines, metal processing, metal processing equipment, etc., can solve the problems of increased labor costs and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

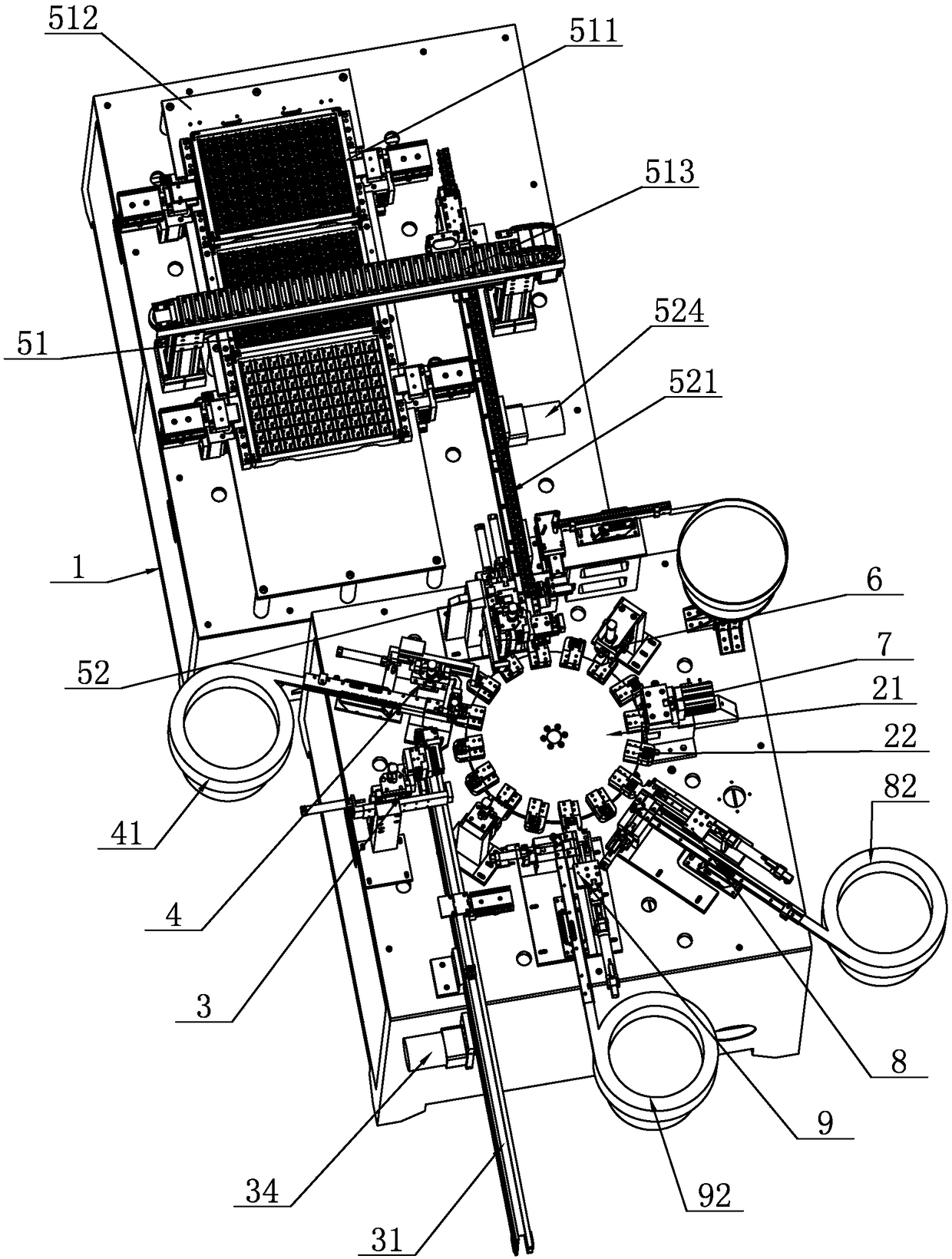

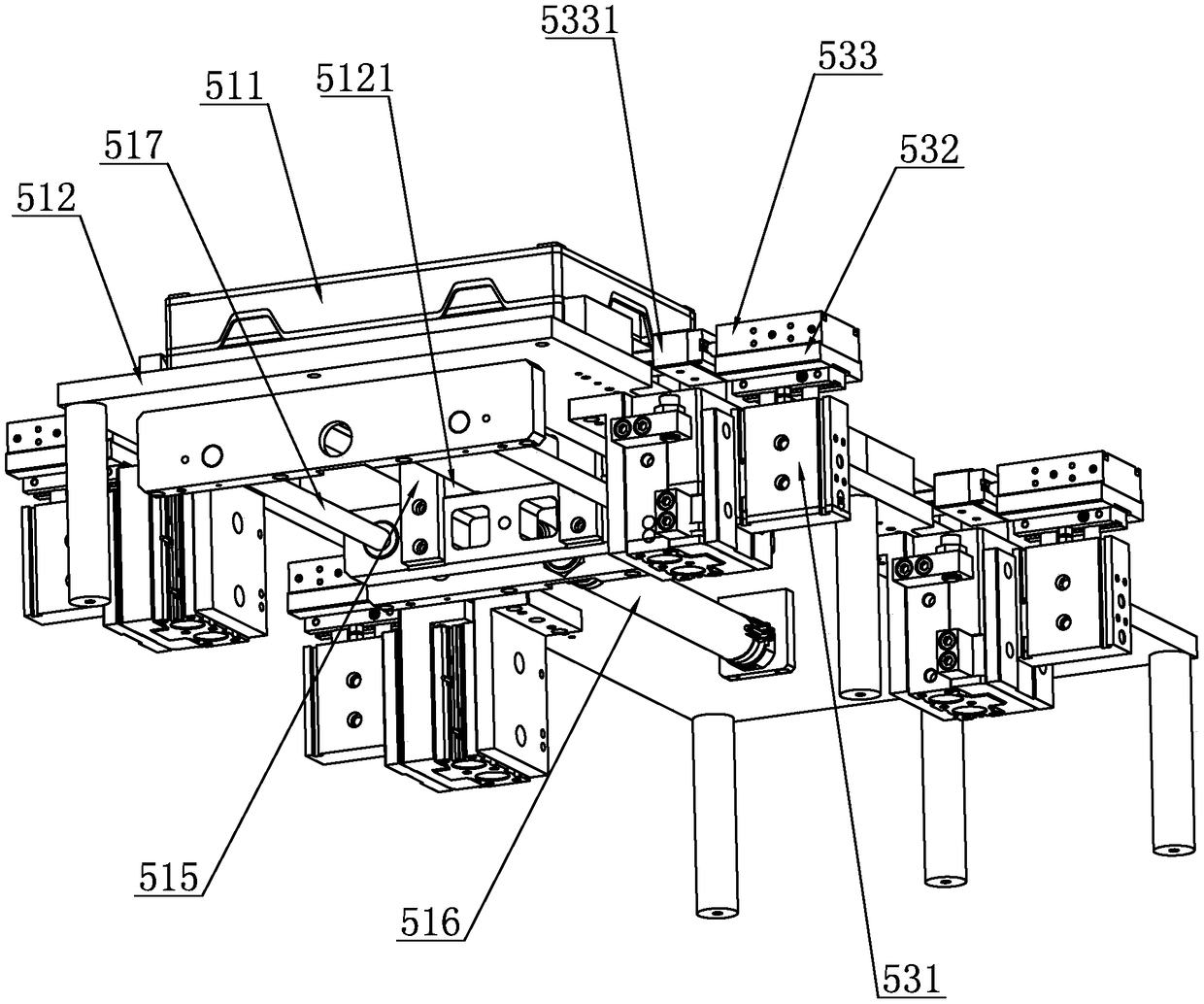

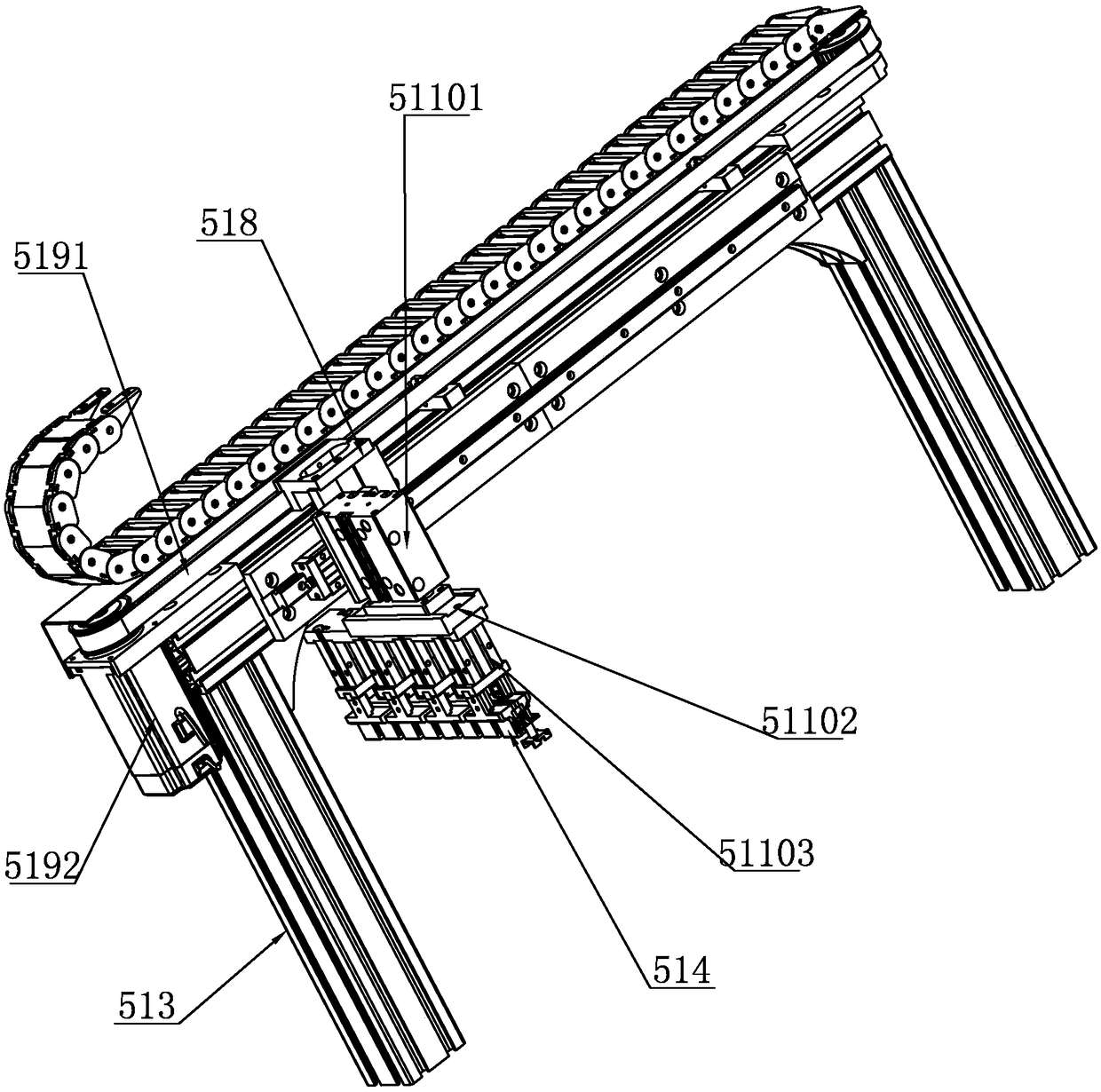

[0039] Such as Figure 1-Figure 14 As shown, an automatic loading and assembling device for a coil bobbin includes a frame 1, on which a clamp mechanism 2, an assembly mechanism and a feeding mechanism 3 are arranged, the clamp mechanism 2 includes a turntable 21, and the turntable 21 is rotatably arranged on the machine On the frame 1, the frame 1 is provided with a drive mechanism for driving the turntable 21 to rotate. The upper end surface of the turntable 21 is evenly distributed along its circumferential direction with several clip bodies 22 for placing the coil skeleton. The clip body 22 includes an upper clip body 221 and a lower clip body. The clamp body 222, the lower clamp body 222 is fixedly arranged on the turntable 21, the upper clamp body 221 is fixedly arranged on the lower clamp body 222, and the accommodation groove 223 for the coil skeleton A1 is formed between the upper clamp body 221 and the lower clamp body 222 , the bobbin A1 is placed on the accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com