Inspecting apparatus and inspecting method for truss bridge

A technology for inspection devices and trusses, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as low inspection and maintenance efficiency, cumbersome walking procedures, poor safety performance, etc., and achieve high inspection efficiency, reduced cost, and fast operation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below by means of the accompanying drawings. It should be noted that the term "transverse" in the following orientation refers to the horizontal direction on the cross section of the truss bridge, and "longitudinal" refers to the extending direction along the truss bridge.

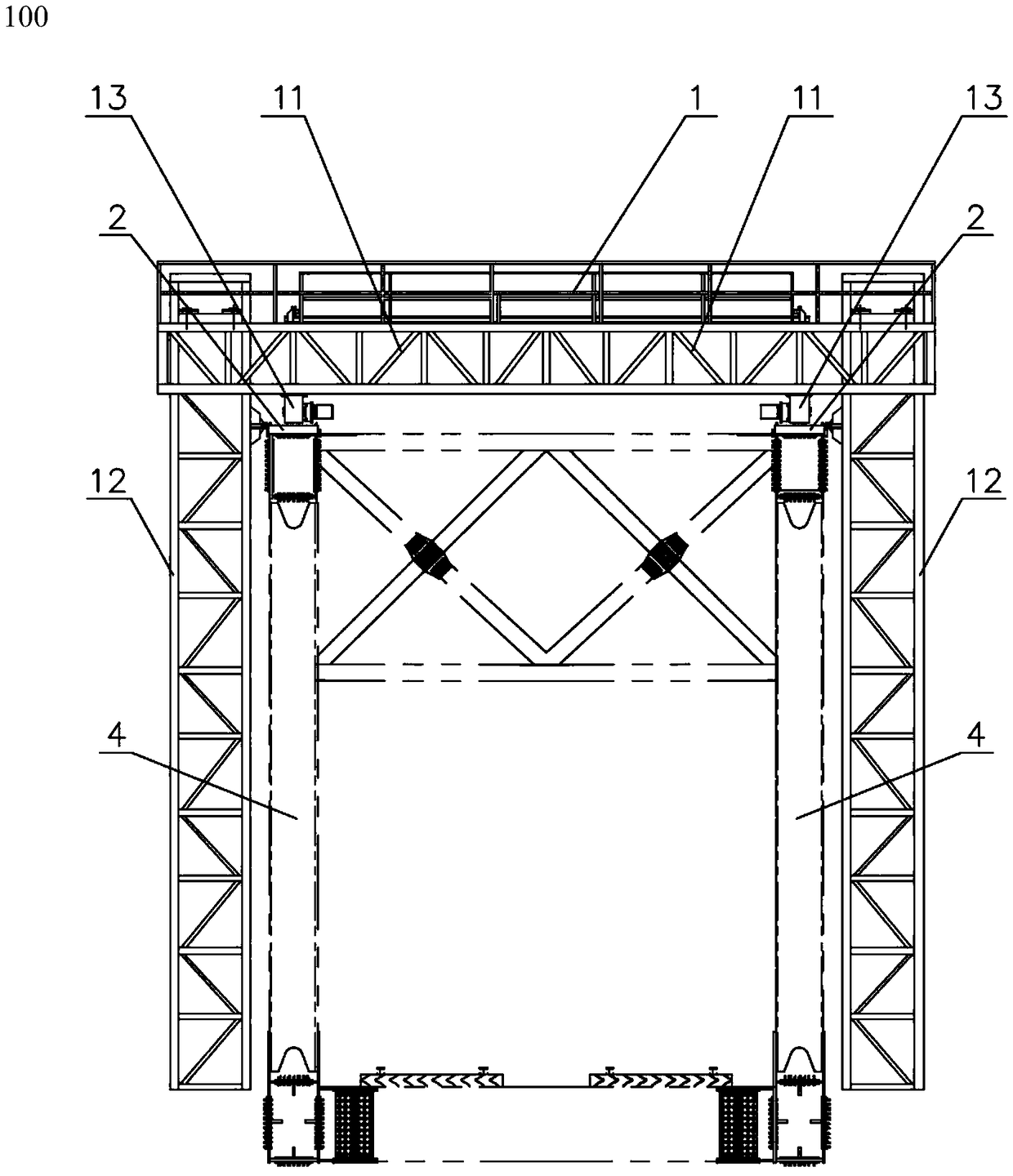

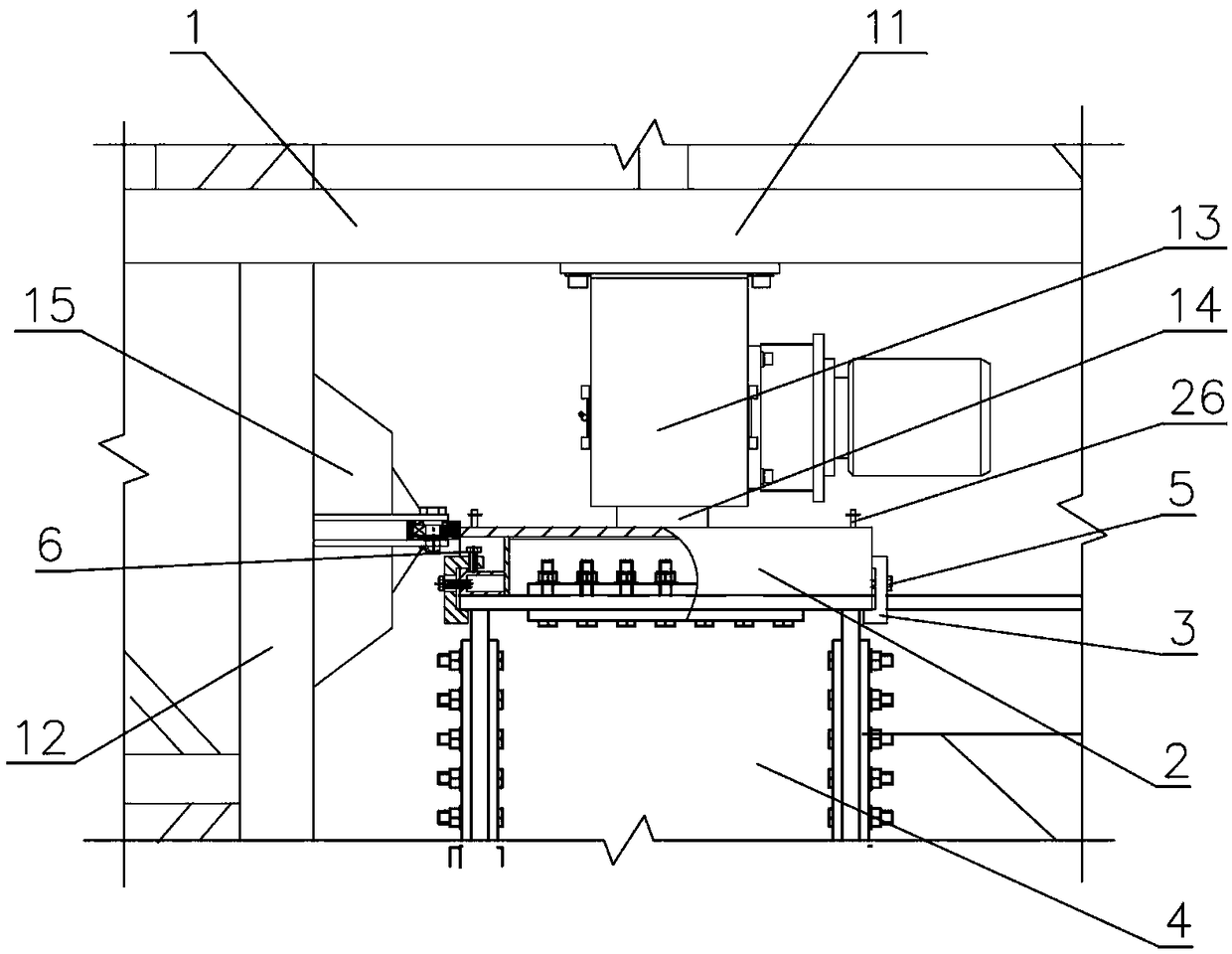

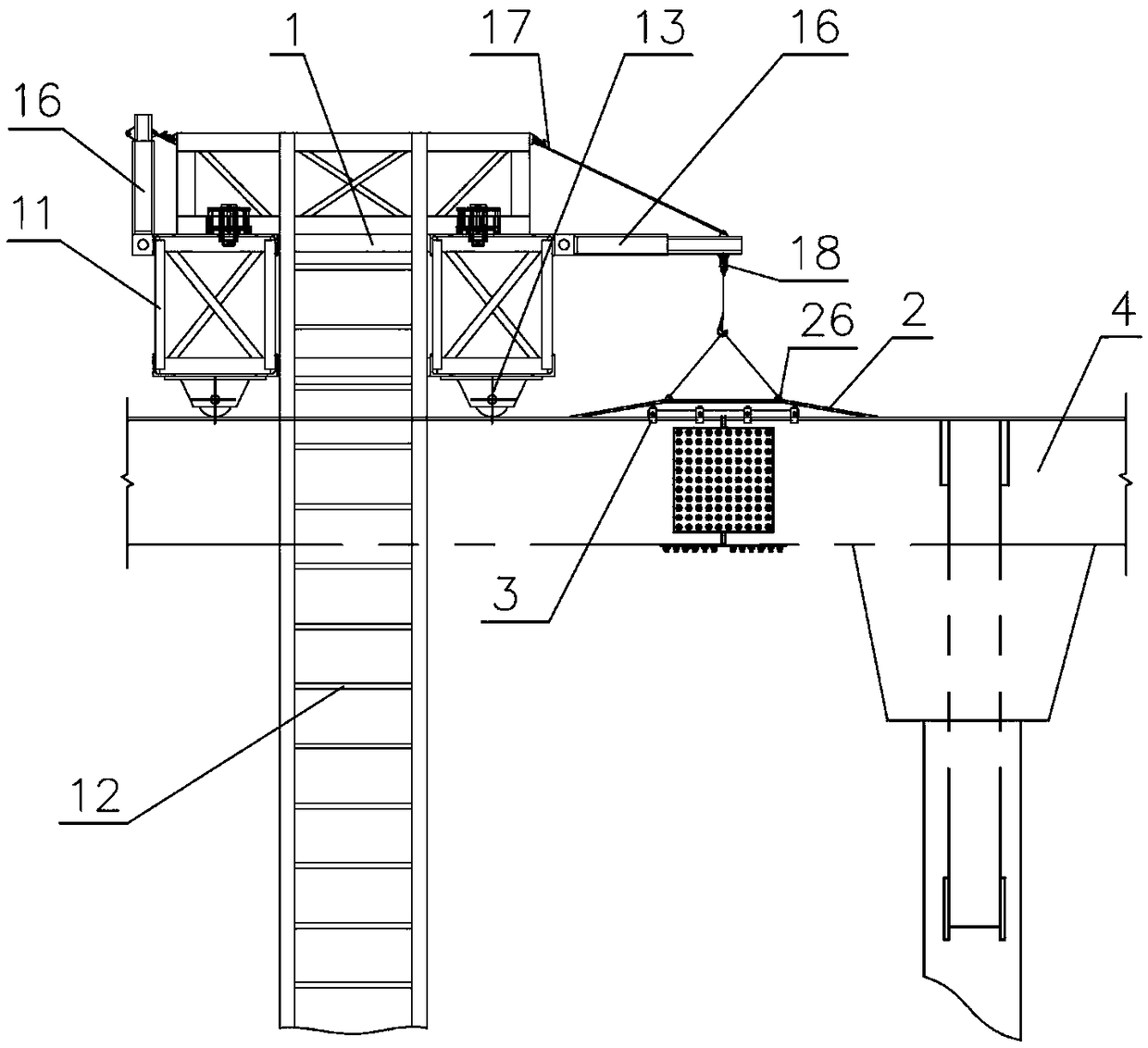

[0028] figure 1 A front view of an inspection device 100 for a truss bridge according to the present invention is shown. Such as figure 1 As shown, the inspection device 100 includes an inspection vehicle 1 . The inspection vehicle 1 includes a traveling mechanism 13 , and in one embodiment, the inspection vehicle 1 is provided with four traveling mechanisms 13 . Such as figure 2 Shown, be provided with traveling wheel 14 below running gear 13. The inspection vehicle 1 drives the traveling wheels 14 to move longitudinally on top of the upper chord of the steel truss girder 4 of the truss bridge through the traveling mechanism 13 . A horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com