Bridge pier column formwork

A formwork and pier column technology, which is applied in the field of formwork, can solve problems such as the impact of pier column quality, the impact of formwork reuse, and the impact on the appearance quality of pier columns, and achieve the effect of preventing concrete leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

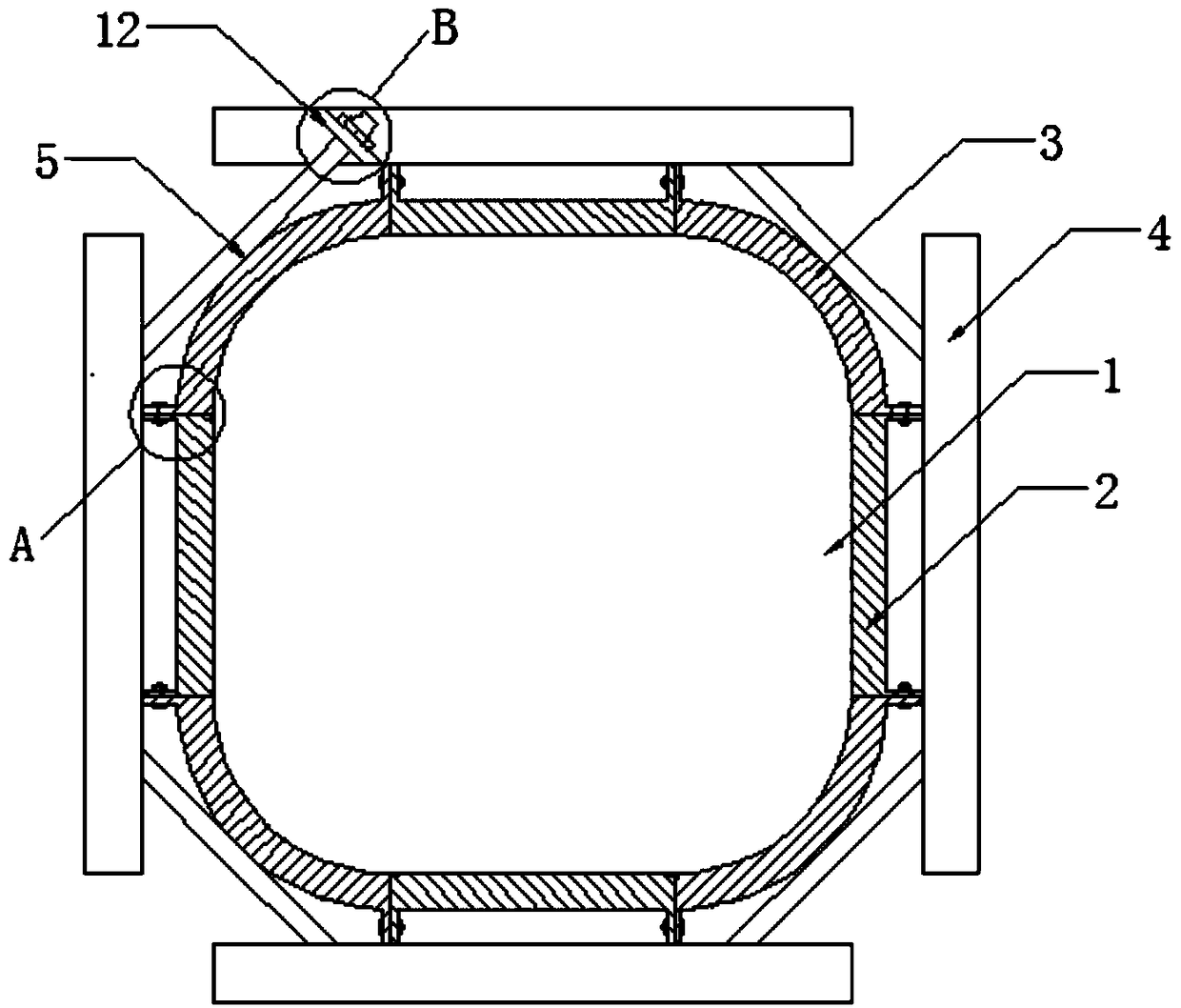

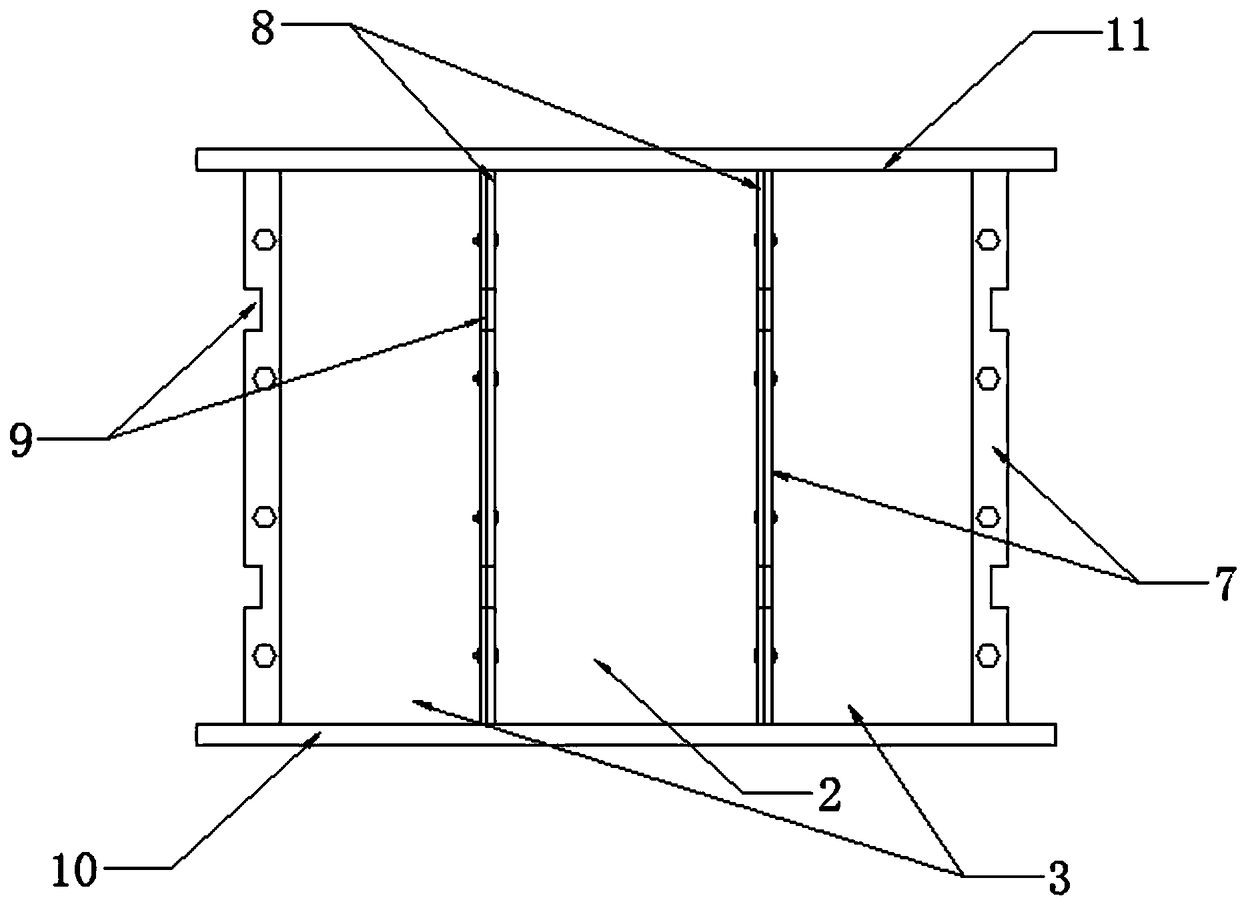

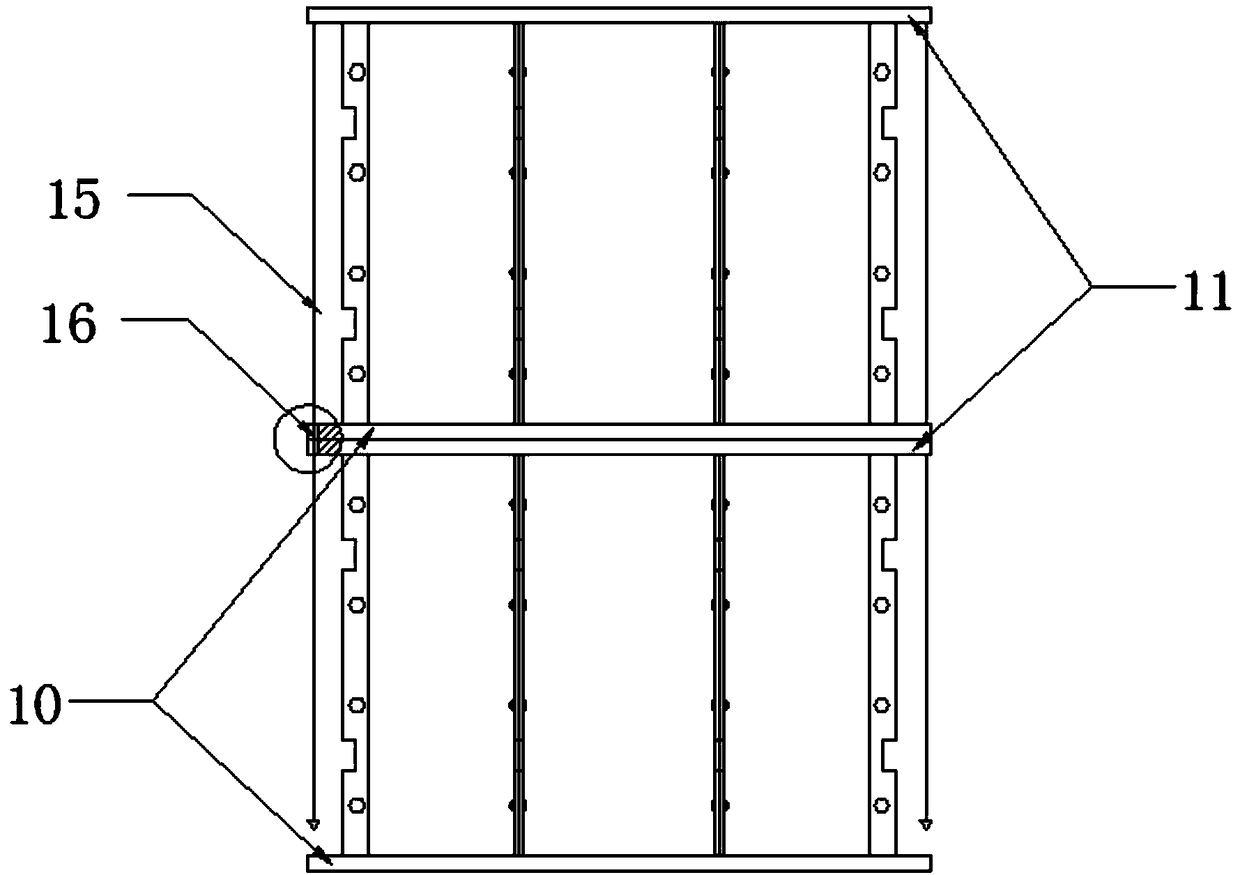

[0022] Such as Figure 1-6 As shown, a bridge pier column formwork of the present invention comprises a pier column formwork 1, a reinforcing bar 4 and a connecting rod 5, and the pier column formwork 1 includes four straight section formworks 2 and four curved section formworks 3, and four straight section formwork forms Both ends of the 2 outer sides are fixedly provided with a first fixed rod 7, and the two ends of the four curved section templates 3 are fixedly provided with a second fixed rod 8, and the first fixed rod 7 and the second fixed rod 8 are threadedly connected. One side of the first fixed rod 7 and one side of the second fixed rod 8 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com