Method for overlapping non-supported bottom of fabricated shear wall structure

A shear wall and unsupported technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult construction, high construction cost, high technical requirements, etc., shorten the construction period, improve construction efficiency, and save labor and material cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

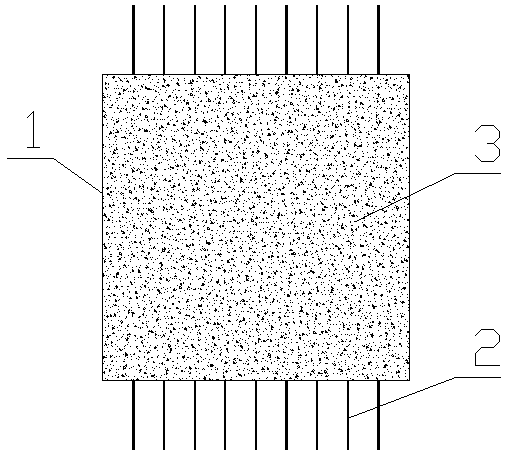

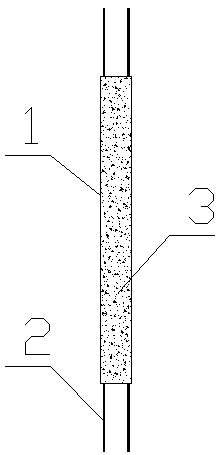

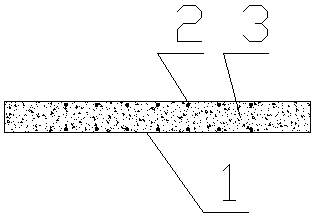

[0019] see figure 1 , figure 2 , image 3 , a method for lapping the unsupported bottom of a prefabricated shear wall structure, which is carried out in accordance with the following steps:

[0020] (1) Hoist the prefabricated wall 1 composed of concrete 3 and steel bars 2 to the installation position, and at the same time support the wall 1 with a jack, and fix the wall 1 through diagonal supports.

[0021] (2) The steel bar 2 poured after binding at the overlap of the steel bar 2 at the bottom of the wall body 1 .

[0022] (3) After the steel bars 2 are bound, the post-cast section at the bottom of the wall 1 is formworked and the concrete 3 is poured.

[0023] (4) After the concrete 3 reaches its strength, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com