A height-adjustable assembled precast concrete laminated floor slab

A technology of prefabricated concrete and superimposed floor slabs, applied in the direction of floor slabs, buildings, building components, etc., can solve the problems of uneven floor surface, manufacturing and hoisting errors, etc., to enhance the integrity, increase the bonding force, and increase the clear height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

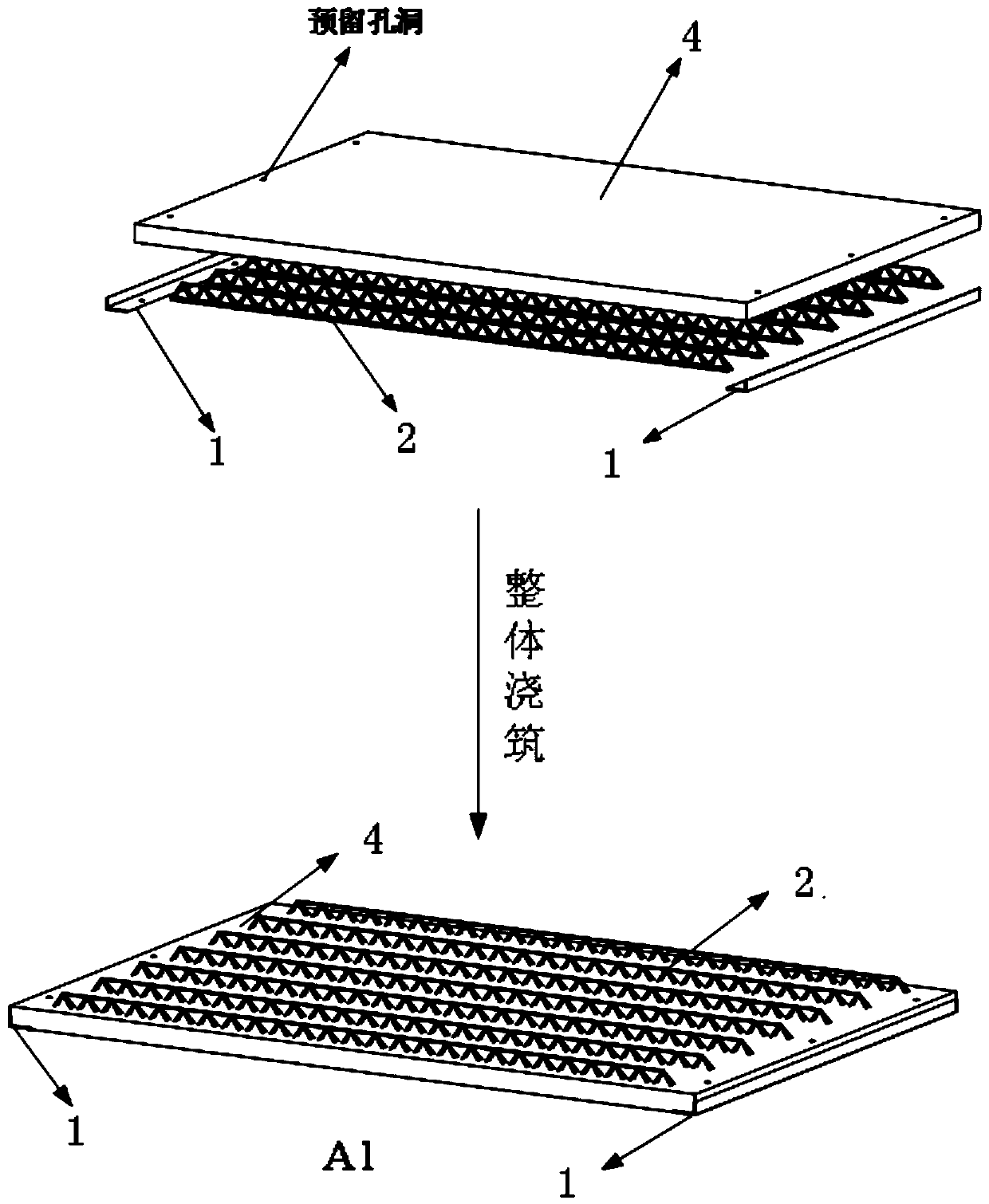

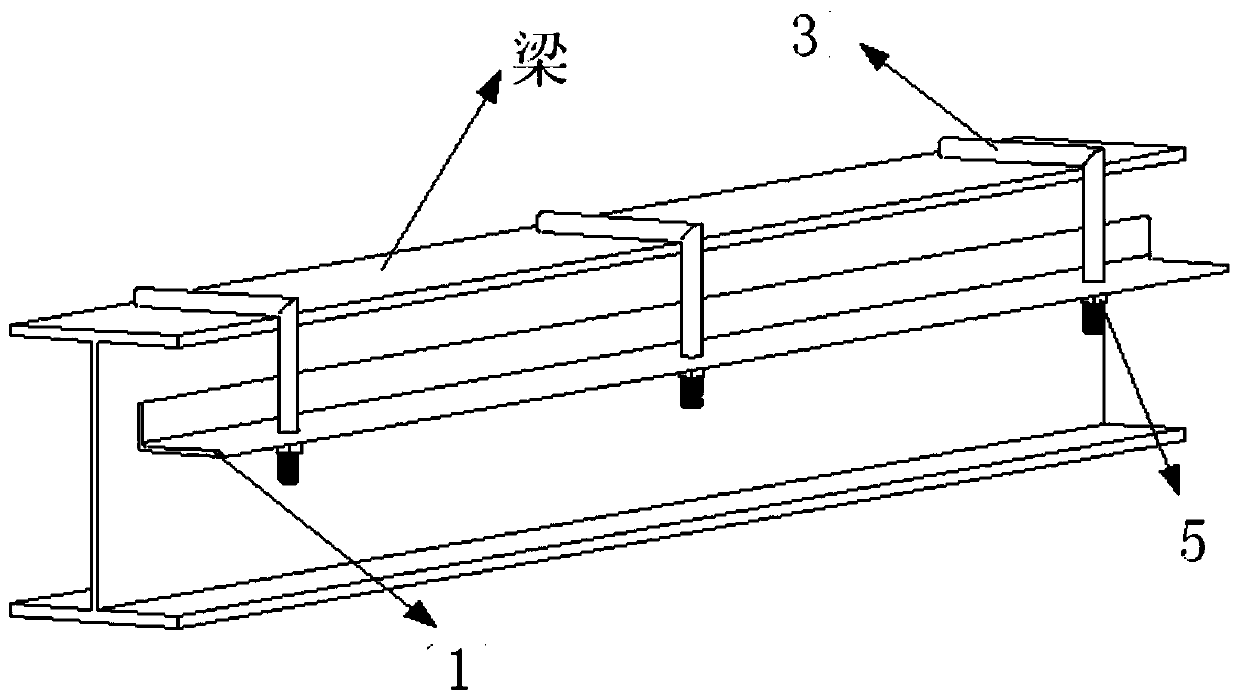

[0024] Attached below Figure 1~4 The specific implementation manner of the height-adjustable assembled prefabricated concrete laminated floor slab of the present invention is described.

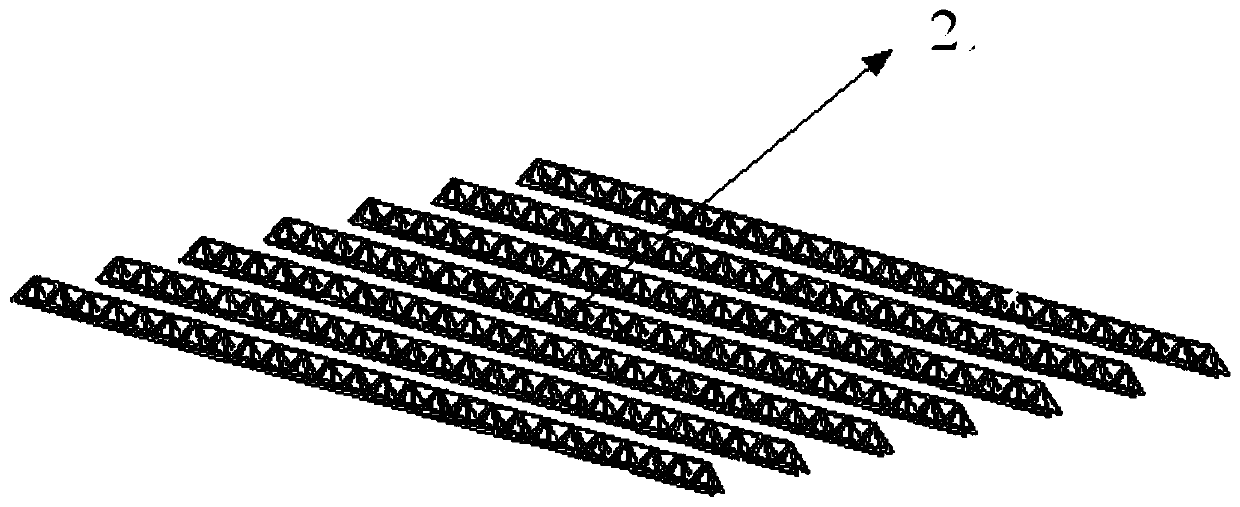

[0025] As shown in the drawings, a height-adjustable assembled prefabricated concrete laminated floor slab of the present invention includes angle steel 1 , steel bar truss 2 , L-shaped screw rod 3 , concrete 4 and nut 5 .

[0026] The angle steel 1, the concrete 4 and the steel truss 2 together form the component A1, and the production of A1 is completed in the factory; the steel truss 2 is distributed at the bottom of the prefabricated slab as the stress reinforcement; two angle steels are arranged on both sides of the prefabricated slab along the direction of the beam At the bottom, holes are made on the angle steel 1 before pouring; when pouring the prefabricated slab, a hole of the same size is reserved on the prefabricated slab at the position corresponding to the opening of the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com