A height-adjustable prefabricated concrete laminated floor slab

A technology of prefabricated concrete and laminated floors, which is applied to floors, buildings, building components, etc., can solve problems such as uneven floor surfaces, achieve the effects of enhancing integrity, improving assembly accuracy, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Attached below Figure 1~5 The specific implementation manner of the height-adjustable precast concrete laminated floor slab of the present invention is described.

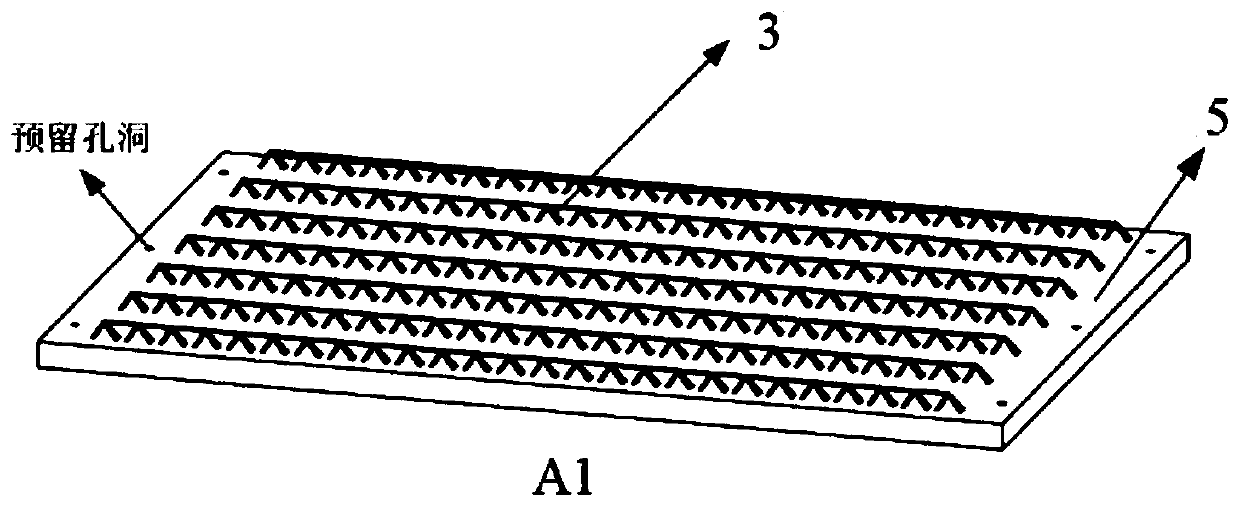

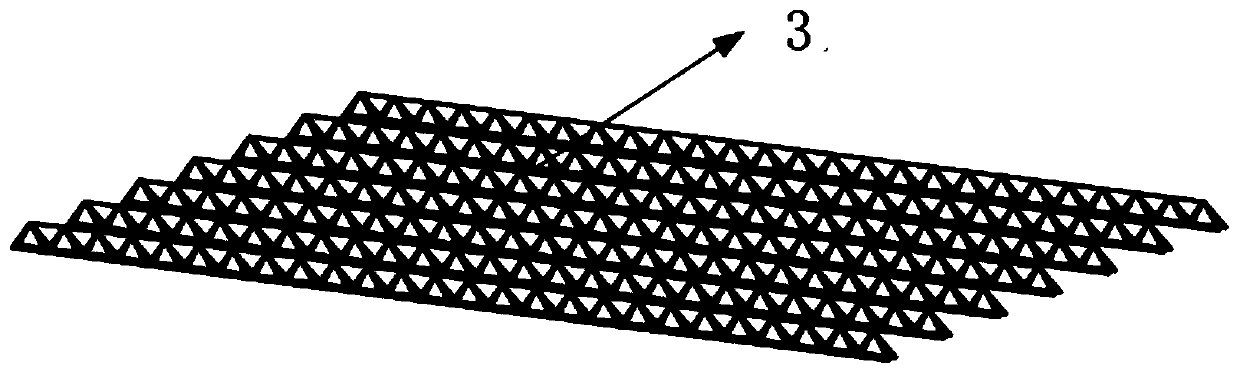

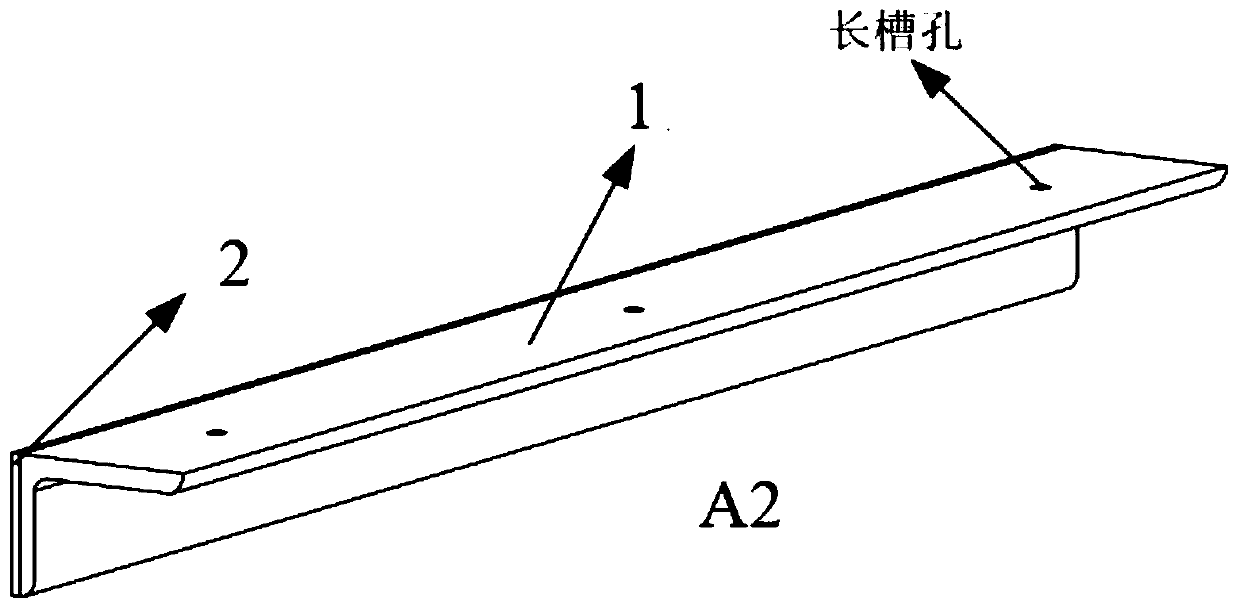

[0032] As shown in the accompanying drawings, a height-adjustable fabricated laminated floor slab of the present invention includes angle steel 1 , soft material 2 , steel bar truss 3 , L-shaped screw 4 , concrete 5 and nut 6 .

[0033] Concrete 5 and steel bar truss 3 together form member A1, and steel bar truss 3 is arranged at the bottom of concrete 5 to act as a stress bar. When member A1 is poured, holes are reserved along both sides of the beam direction; on the long side of angle steel 1, the position corresponding to member A1 Slot holes are opened, and the soft material 2 is pasted on the short side of the angle steel 1 to form component A2. Both components A1 and A2 are processed and manufactured in the factory; The vertical rod of the screw rod 4 passes through the holes on the components A1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com