Structural column construction device and method

A technology of construction equipment and construction methods, which is applied in building construction, on-site preparation of building components, formwork/formwork/working frame, etc., which can solve the problems of low construction efficiency, defects in structural columns, and impacts on the load-bearing and support of structural columns effect and other issues, to achieve the effect of scientific construction method, novel structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

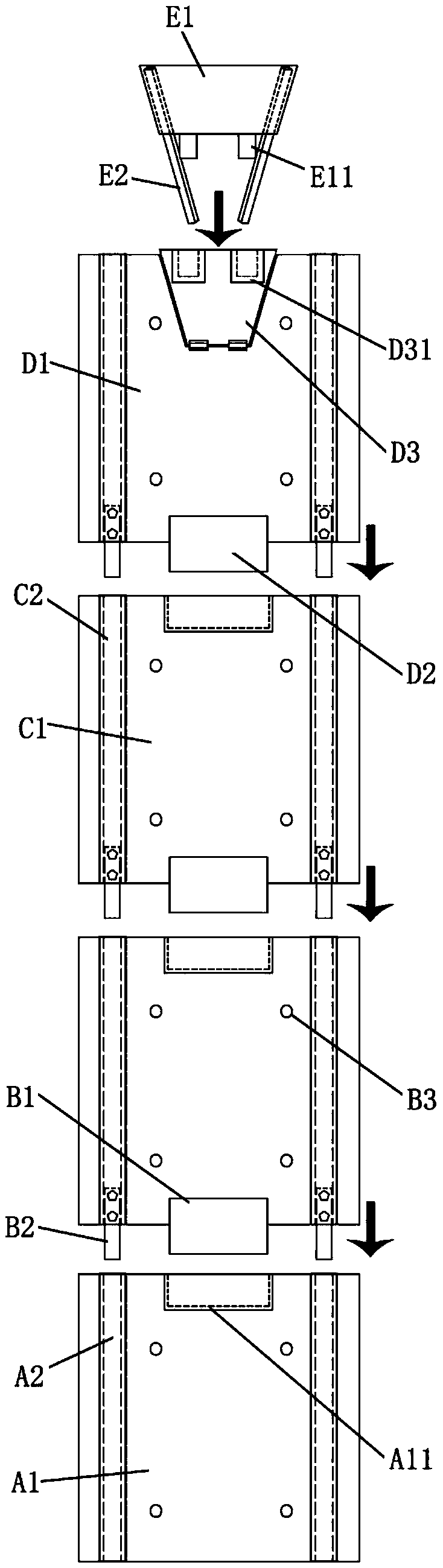

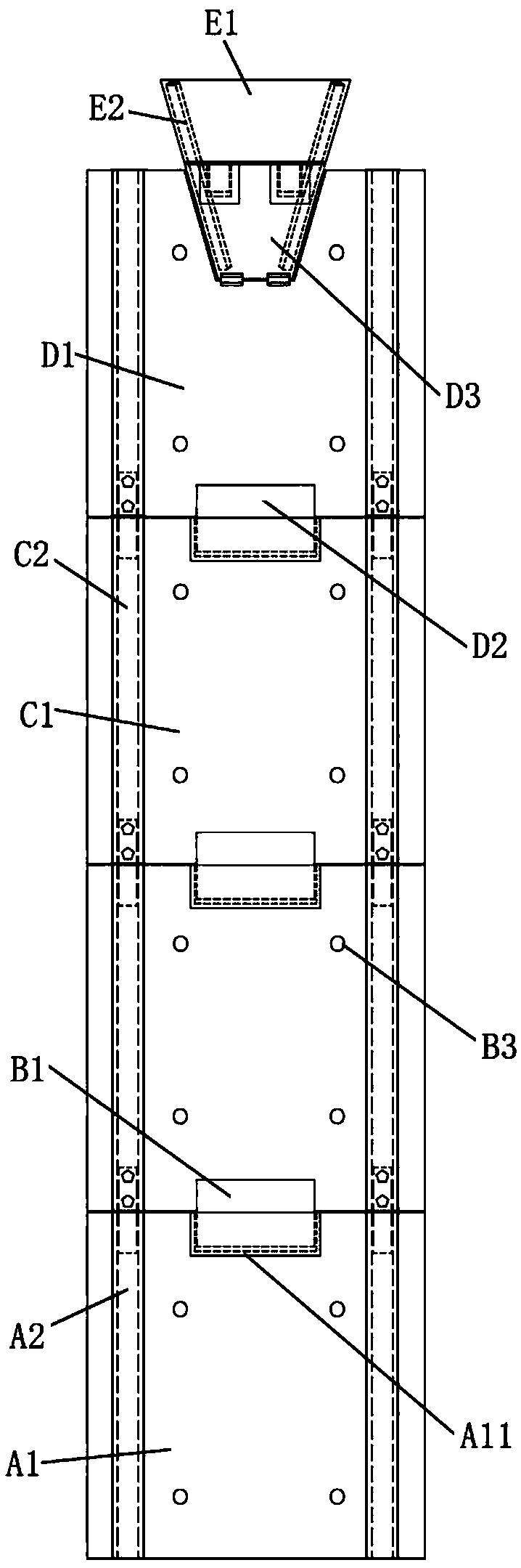

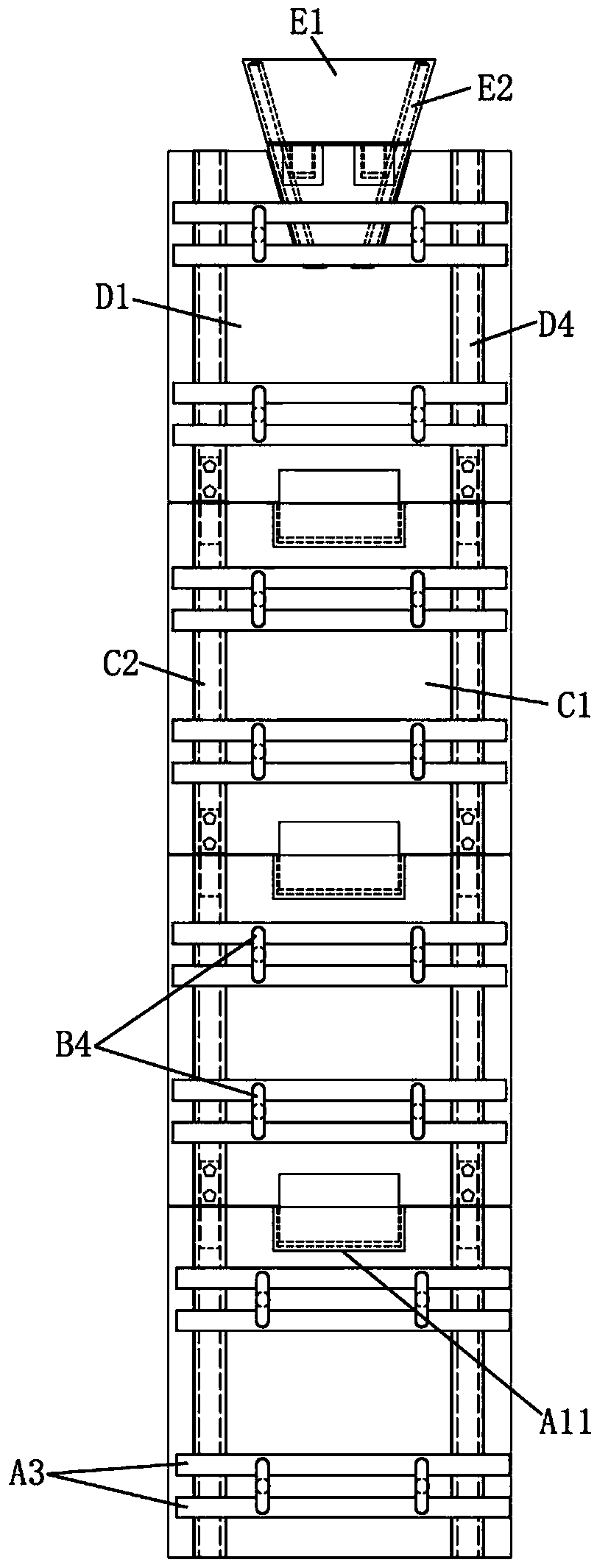

[0048] like figure 1 , figure 2 , image 3 As shown, a construction column construction equipment is composed of a bottom formwork body, 2 middle formwork bodies, a top formwork body, and a feed guide bucket, and is characterized in that,

[0049] The bottom formwork body is located at the lowermost end, the top of the bottom formwork body is connected with a first intermediate formwork body, the top of the first intermediate formwork body is connected with a second intermediate formwork body, and the top of the second intermediate formwork body The top is connected with the top mold frame body, and the feeding guide bucket can be buckled downward to the front upper end of the top mold frame body;

[0050] The bottom formwork body, the first middle formwork body, the second middle formwork body, the top formwork body, and the feeding guide hopper are combined to form a pouring formwork, and the pouring formwork is surrounded by the steel frame and the periphery of the horse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com