Control structure of a shifting fork

A shift fork and control structure technology, which is applied in the field of automobile transmission, can solve the problems of large space in the transmission, low precision of gear selection, and large radial area occupied, and achieve small space requirements, improve assembly cycle, and diameter Towards a small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

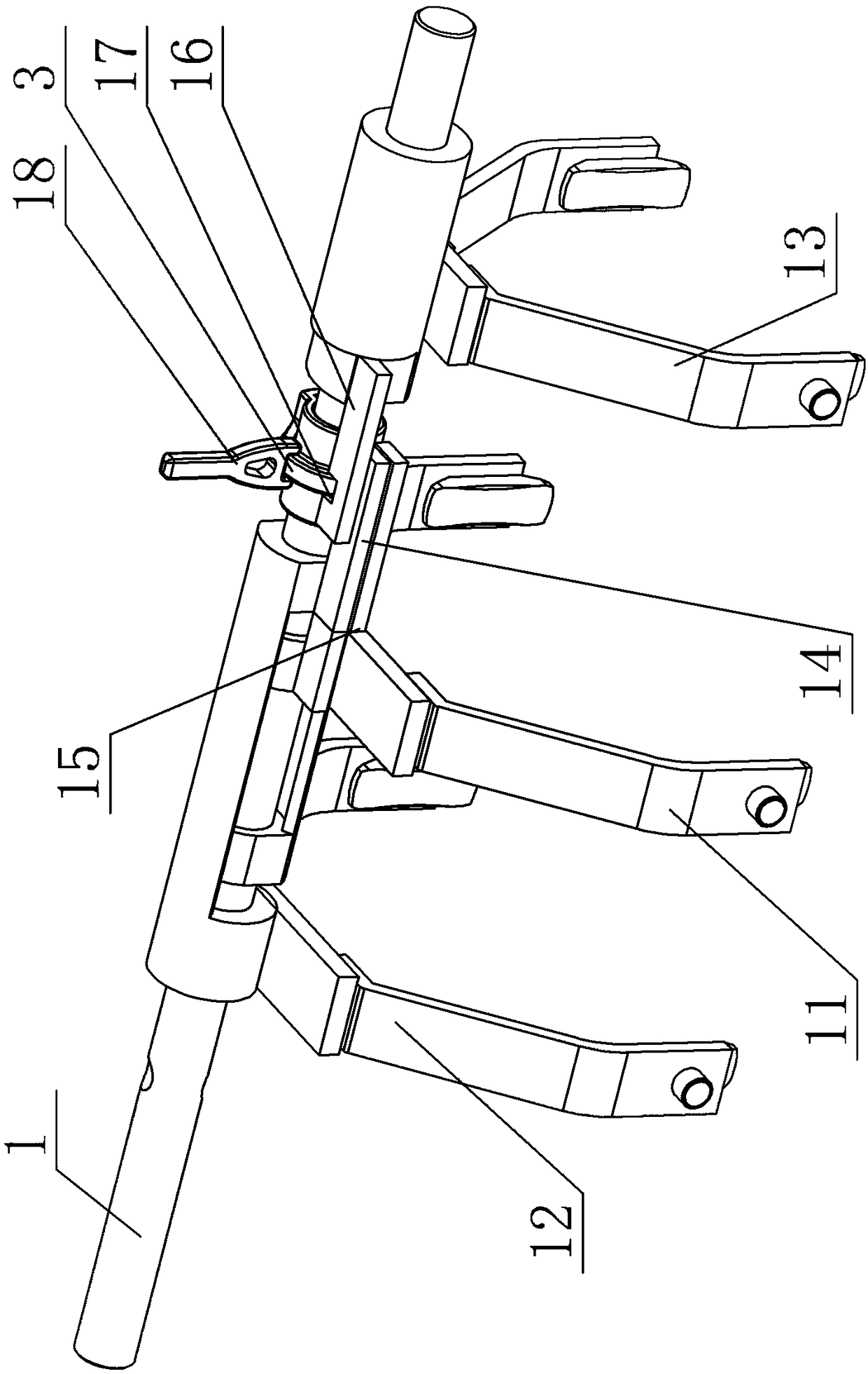

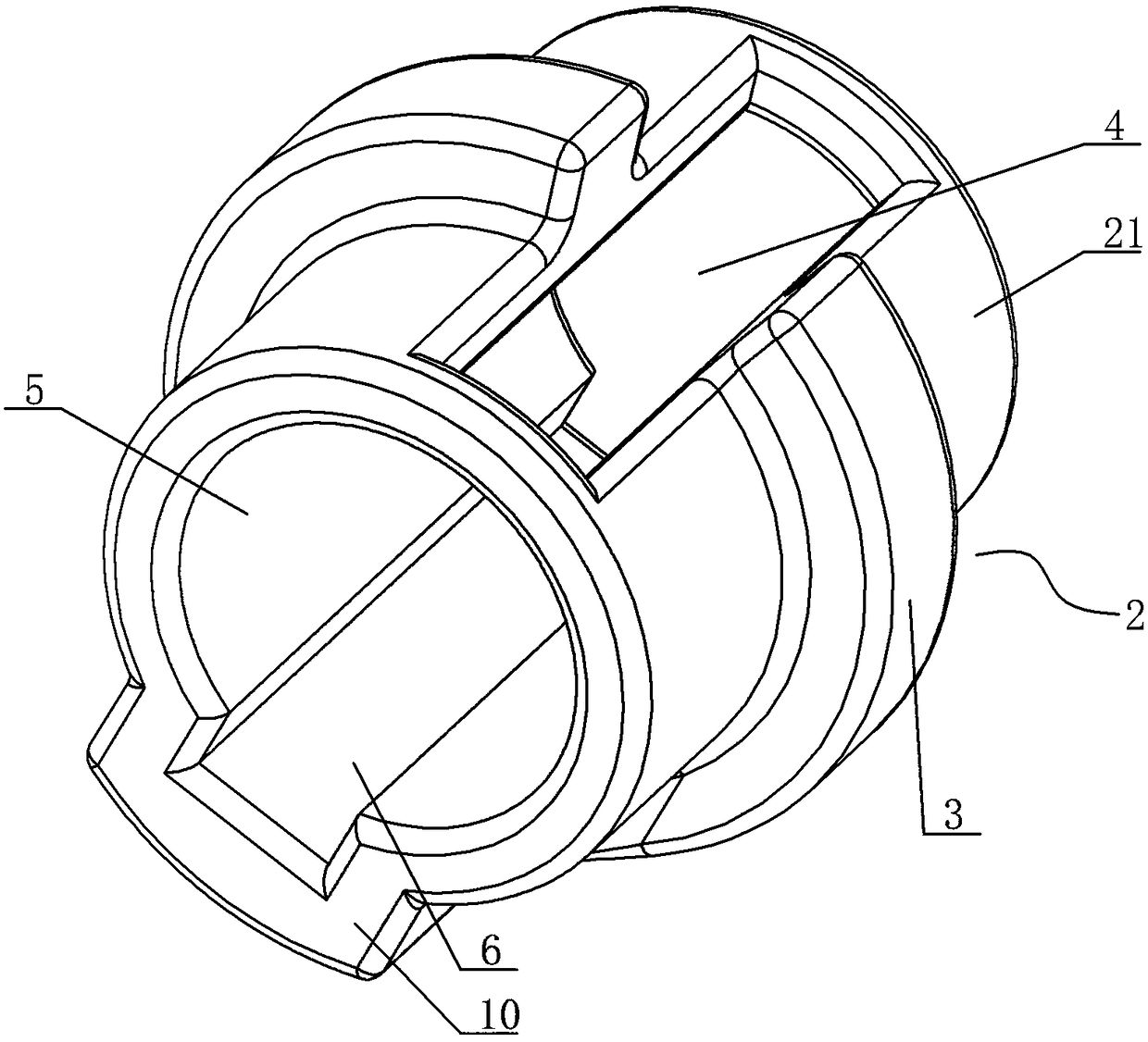

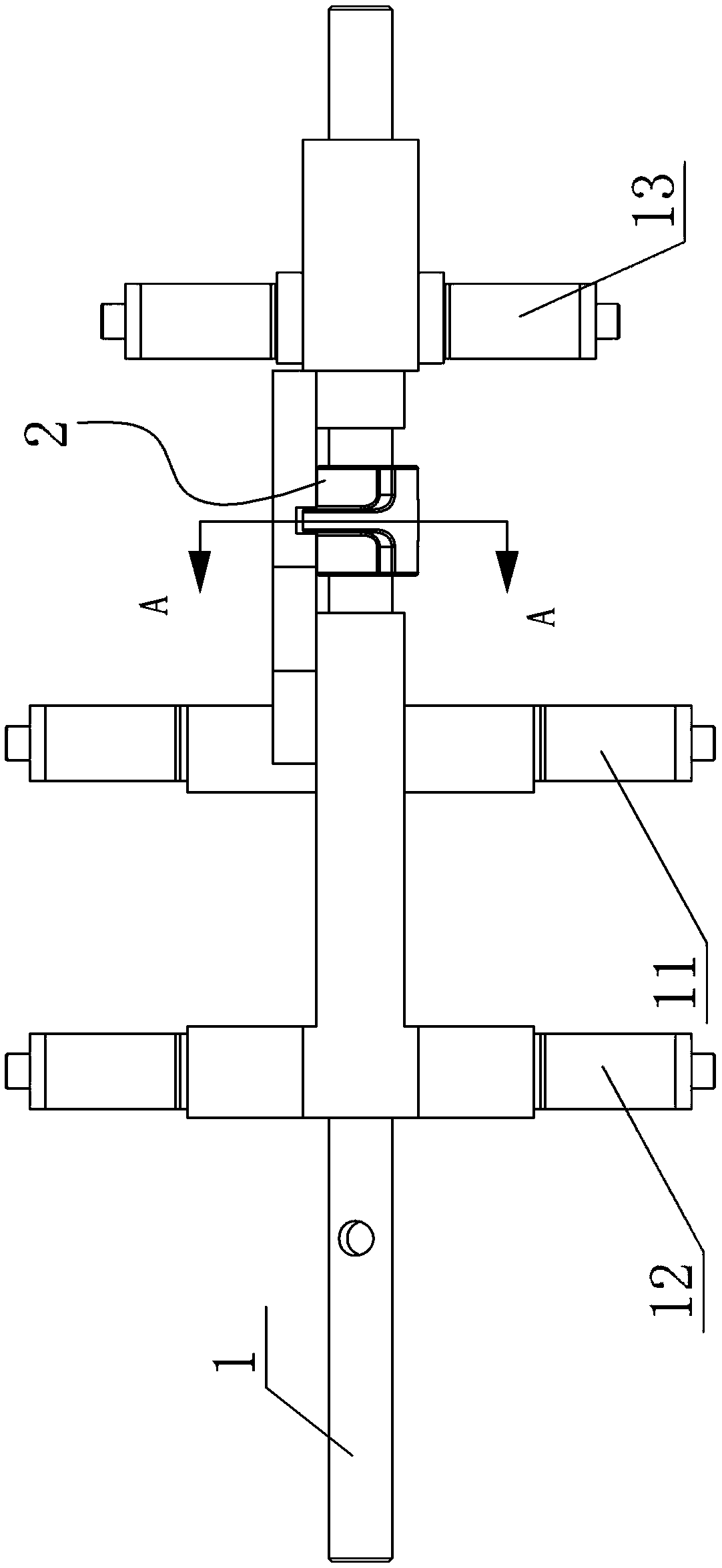

[0024] A control structure for a shift fork, see Figure 1-Figure 6 : It includes a shift fork shaft 1, an interlock device 2, and several shift forks, the input connection parts of several shift forks are respectively set on the shift fork shaft 1, and the input connection parts of the shift forks are correspondingly provided with axial The shift fork slot plates arranged in length, each shift fork slot plate is arranged at different radial positions of the shift fork shaft 2, and all the shift fork slot plates are respectively provided with shift forks corresponding to one axial length position of the shift fork shaft 2 Groove 17, the interlocking device 2 is set in the area of the shifting fork groove corresponding to the shifting fork groove 1, the interlocking device 2 includes an annular boss 3, and the annular boss 3 is clamped to the shifting fork groove 17 The corresponding shift fork slot plate is locked, and the interlocking device 2 also includes an open groove 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com