A double-sided film tearing mechanism for a light guide plate

A light guide plate and double-sided technology, applied in lamination, chemical instruments and methods, lamination auxiliary operations, etc., can solve problems such as low efficiency and poor reliability, achieve low pollution, low processing and manufacturing costs, and strong mechanism stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

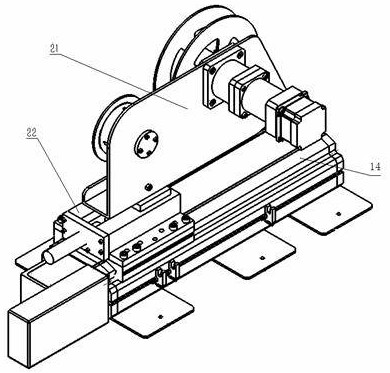

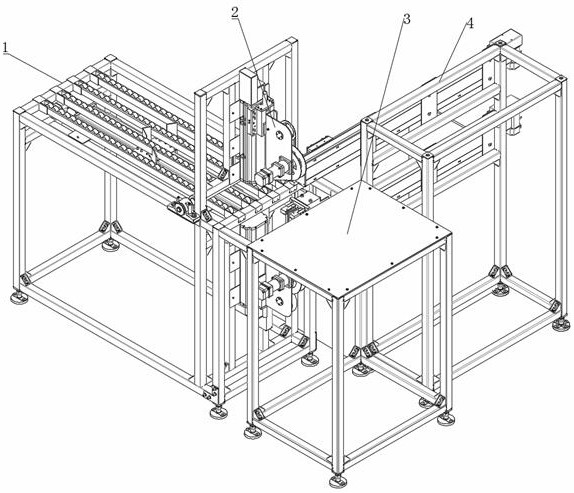

[0037] Embodiment 1: as Figure 1-16 As shown, the double-sided film tearing mechanism of the light guide plate includes a light guide plate pushing mechanism 1, two tape tearing film devices 2, a light guide plate receiving and releasing platform 3, and a waste film recovery mechanism 4; the two tape film tearing devices 2 are symmetrically installed on the On the light guide plate pushing mechanism 1, the light guide plate receiving and releasing platform 3 is set on one side of the tape tearing device; the waste film recycling mechanism 4 is set on the other side of the tape tearing device 2;

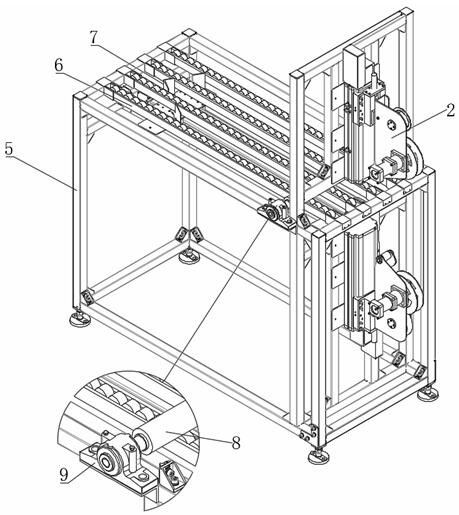

[0038] Wherein the light guide plate pushing mechanism 1 comprises a light guide plate pushing mechanism frame 5, a fluent bar 6, a pushing device 7, a pressure wheel 8, and a pressure wheel installation bearing seat 9; the pushing device 7 is installed on the middle beam of the light guide plate pushing mechanism frame 5 , 4 fluent strips 6 are fixed on the top horizontal frame of t...

Embodiment 2

[0041] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1, the difference is that the pressure roller 8 includes a pressure roller rubber sleeve 10, a first pressure roller shaft 11, a pressure roller bearing 12, and a spring retaining ring 13, and the two pressure roller bearings 12 are respectively installed The two ends of the first pinch shaft 11 are axially positioned by the shaft shoulder and the retaining ring 13. The first pinch shaft 11 is fitted with a pinch rubber sleeve 10, and the two ends of the first pinch shaft 11 are arranged on the The pressure roller is installed in the bearing seat 9; the light guide plate receiving and releasing platform 3 includes a cover plate 62 and a platform frame 63, the platform frame 63 is constructed of aluminum profiles, and the cover plate 62 is installed on the platform frame 63; the light guide plate pushing mechanism frame 5 It is constructed of aluminum profiles and has the advantages of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com