Gyroscope structure test system for small rotor UAV based on six-dimensional force sensor

A six-dimensional force sensor, unmanned rotor technology, applied in instruments, measuring devices, etc., can solve problems such as inability to accurately measure flight data, difficulty in simulating the flight state of UAVs, and achieve the effect of optimizing engine design and improving engine design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Such as Figure 5 As shown, the test platform of the present invention includes an aluminum alloy support frame 1, a spherical support frame 2, an annular support frame 3, two kinds of connecting parts 4, a support rod 5, a fixing part 6, a sensor 7, a deep groove ball bearing 8 and a linear Bearing 9. Among them, the spherical support frame 2 is assembled into an outer spherical frame through the connecting piece 4; the connecting piece 4 is equipped with a deep groove ball bearing 8, and the connecting piece 4 is inserted into the linear bearing 9 through the rotating shaft; the linear bearing 9 is embedded in the aluminum alloy support frame 1; Both ends of the support rod 5 are connected to the ring support frame 3 through shafts, and the drone is connected to the support rod 5 through the fixing part 6; the sensor 7 is connected to the middle part of the aluminum alloy support frame 1 through screws.

[0050] 1. The aluminum alloy support frame 1 is connected by s...

Embodiment 2

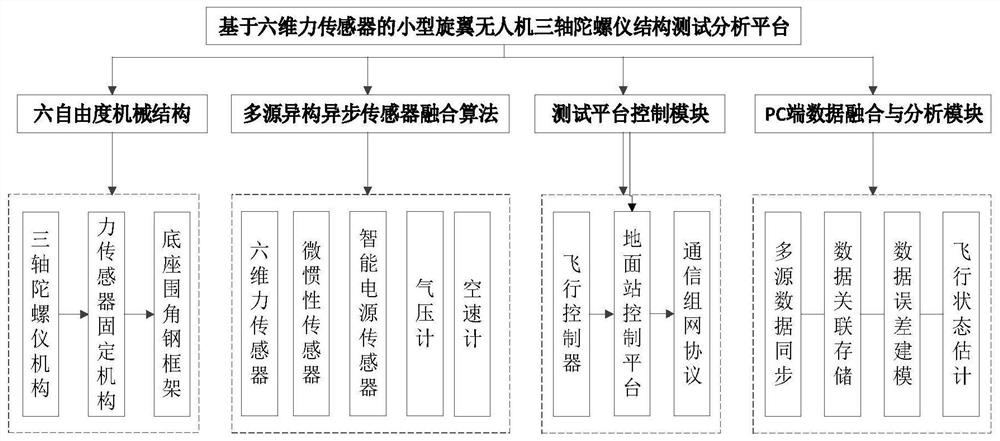

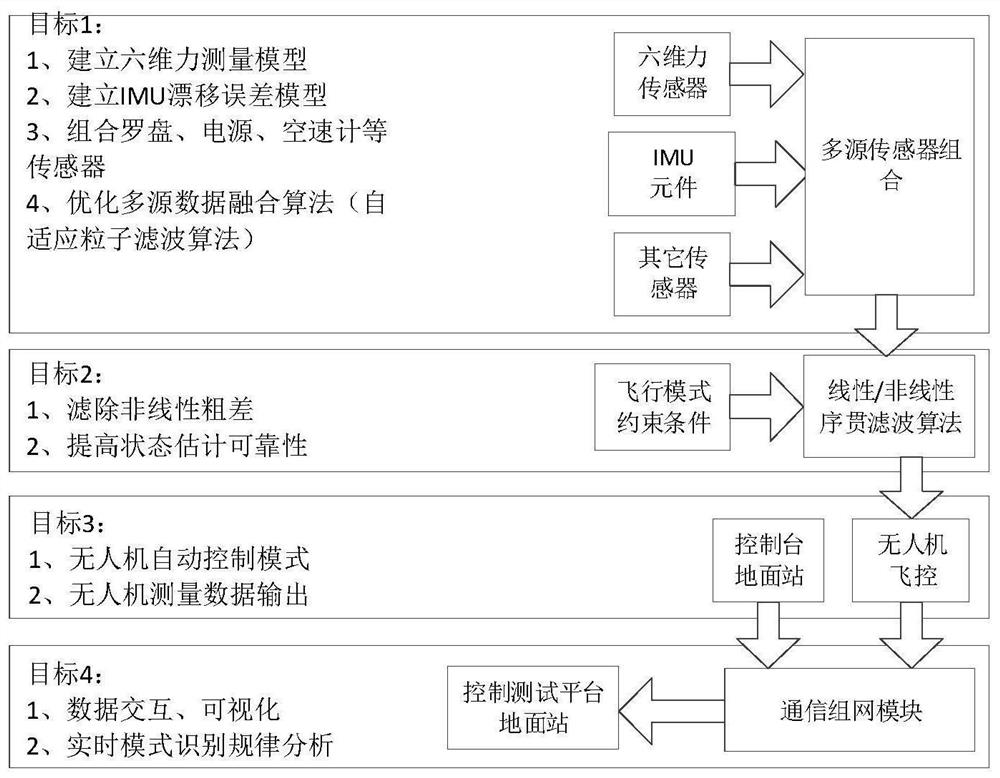

[0065] Such as figure 1 , figure 2 , image 3 As shown, the small rotor UAV test and analysis system based on the six-dimensional force sensor includes:

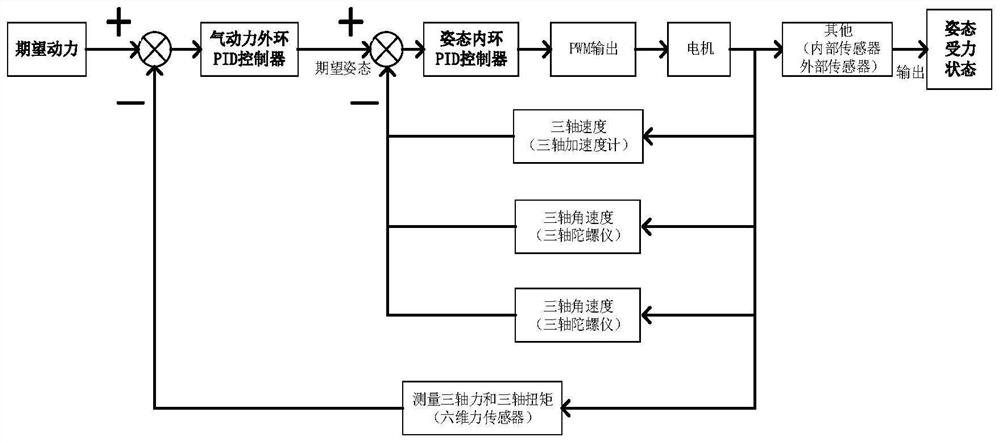

[0066] The three-degree-of-freedom mechanical structure used as a test platform is used for small unmanned aerial vehicles to perform arbitrary movements of three degrees of freedom in pitch, roll and yaw, including: test frame, spherical support frame, circular support frame, connectors, and support rods , fixed parts, deep groove ball bearings and linear bearings; wherein the spherical support frame is assembled into an outer spherical frame through the connecting parts; the deep groove ball bearings are installed in the connecting parts, and the connecting parts are inserted into the straight line through the rotating shaft In the bearing; the linear bearing is embedded in the support frame; both ends of the support rod are connected to the ring support frame through a shaft, and the fixing member is connected to the s...

Embodiment 3

[0076] On the one hand, the data analysis method of the test platform can use the three-dimensional force sensor and the internal sensor of the UAV flight control to obtain flight lift, thrust and other data in the general flight state, combined with air velocity, etc., so as to perform flight dynamics analysis and aerodynamic analysis; On the one hand, the simulation of the real flight attitude of the UAV can be realized through the three-degree-of-freedom test platform; Figure 10 The sensors in the test platform shown are all treated with three defenses. By placing the test platform in different environments (such as high and low temperature, wind tunnel, electromagnetic field, etc.), the flight attitude and force of the drone under special conditions can be simulated. situation, so as to analyze the influence of special conditions on all aspects of the UAV and the stability of the UAV:

[0077] (1) High and low temperature test. The test platform is placed in a vacuum ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com