Two-stage air-suspending centrifugal air compressor comprehensive performance test-bed

A centrifugal air compressor, comprehensive performance technology, applied in the field of air compressors, can solve the problems of cumbersome testing, inability to monitor the working state of the air compressor or performance test, and narrow use range, so as to improve work efficiency and accuracy, Improve the test and working environment, and the scientific and reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

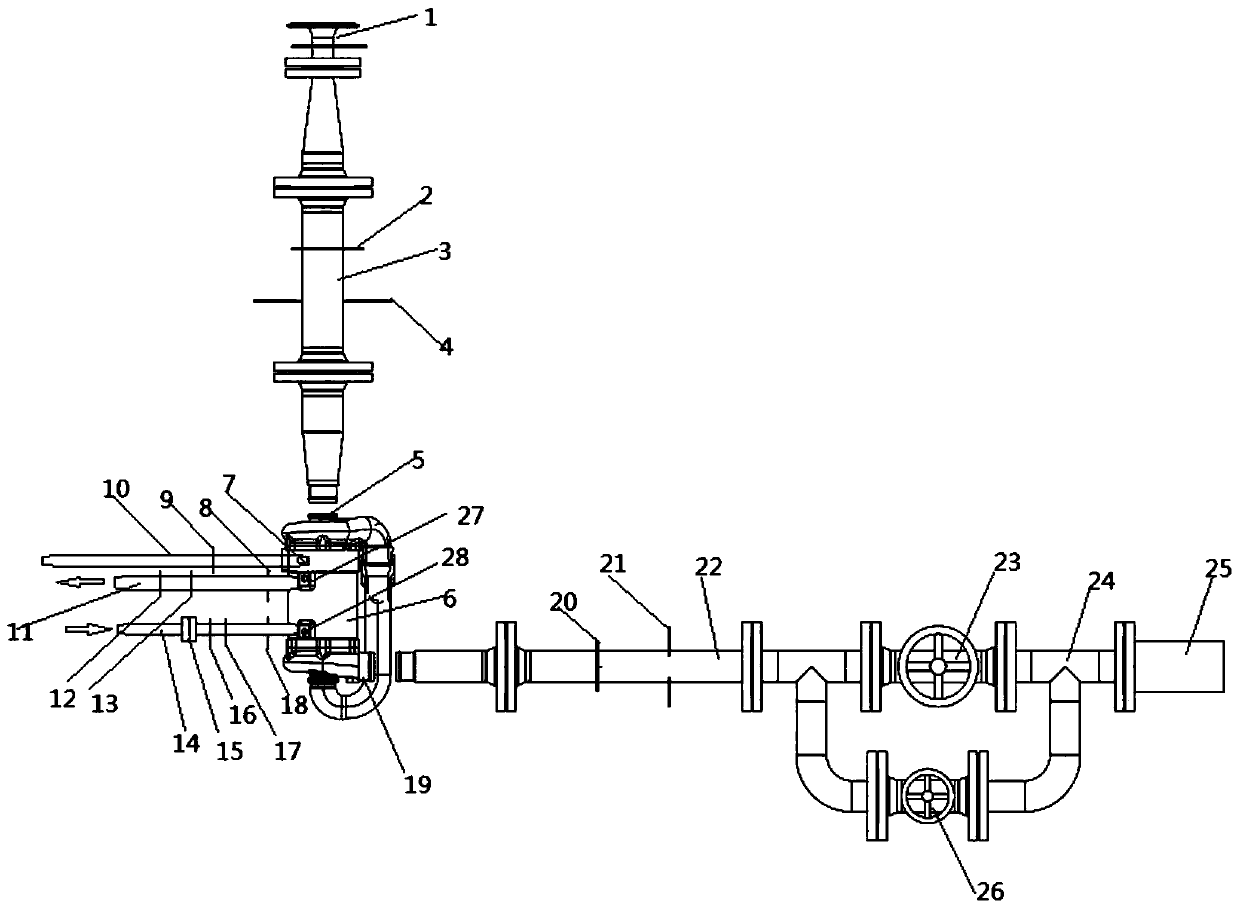

[0023] see figure 1 , a comprehensive performance test bench for a two-stage air-suspended centrifugal air compressor, comprising a first-stage air inlet pipeline 3 connected to the first-stage air inlet 5 of the air compressor to be tested 6, and a first-stage air inlet pipeline 3 connected to the air compressor to be tested 6 The secondary exhaust end pipeline 22 connected to the secondary air intake port 19, the cooling air discharge pipeline 10 connected to the cooling air exhaust joint 7 of the air compressor 6 to be tested and the cooling water of the air compressor 6 to be measured The cooling water circulation pipeline connected by the water inlet joint 28 and the cooling water drain joint 27,

[0024] The pipeline 3 at the primary air intake end is provided with an intake air flow sensor 1, an intake air pressure sensor 2 and an intake air temperature sensor 4 in sequence,

[0025] The secondary exhaust end pipeline 22 is provided with an exhaust pressure sensor 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com