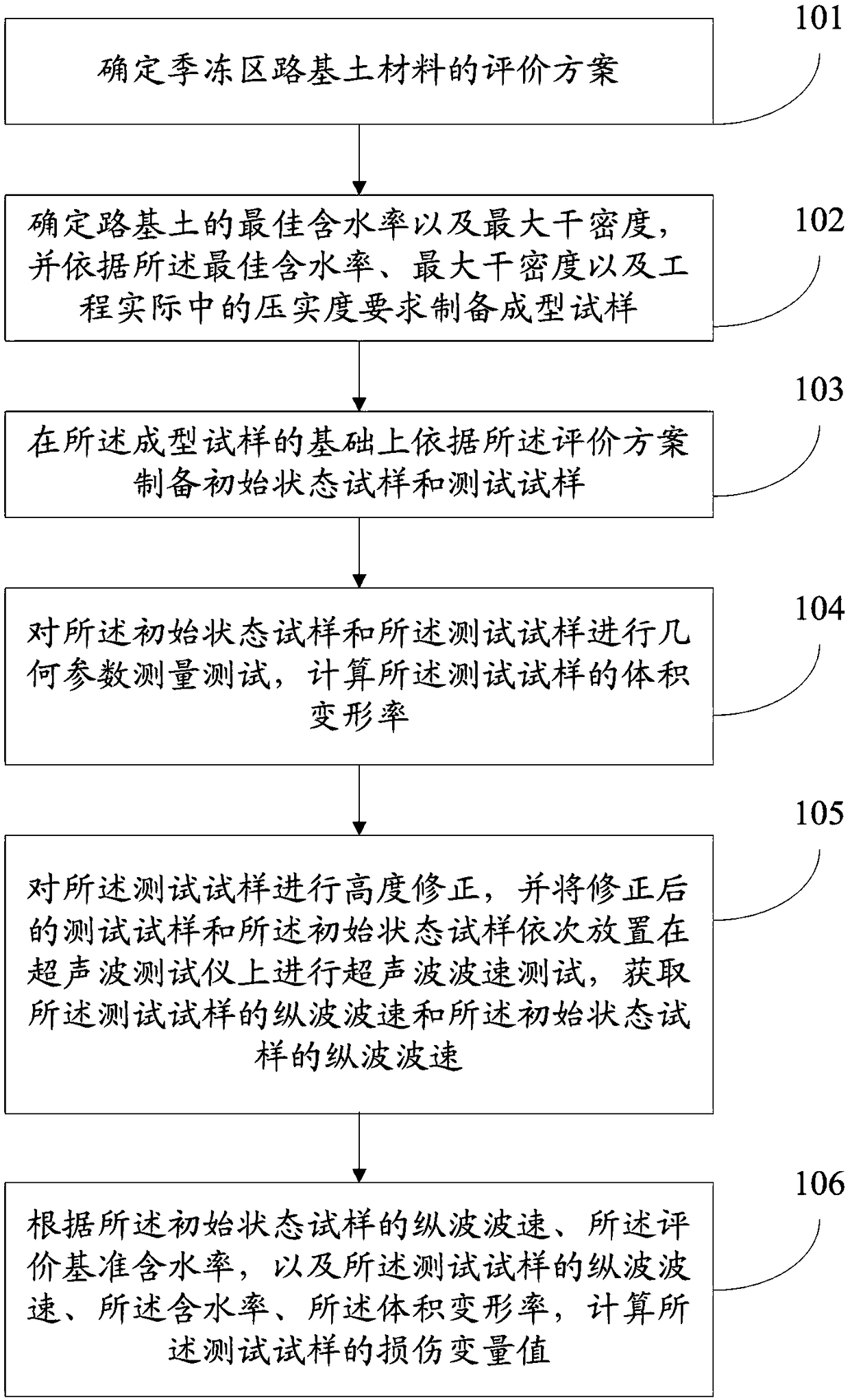

Ultrasonic technology-based method for detecting and evaluating damage of subgrade soil materials in seasonal frozen regions

A technology of material damage and evaluation methods, which is applied in the analysis of solids, materials, and thermal analysis of materials using sonic/ultrasonic/infrasonic waves, which can solve the problem of inability to accurately and comprehensively assess the damage degree of soil damage mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The preparation process of the test sample is as follows:

[0081] Select typical soil samples for damage detection and evaluation.

[0082] Carry out the roadbed soil engineering index test on the typical soil samples, and determine the soil samples that meet the roadbed soil engineering indexes; the roadbed soil engineering indexes include liquid limit, plastic limit, plasticity index, particle composition, moisture content and California bearing ratio Wait.

[0083] The optimal water content and maximum dry density of the soil samples that meet the roadbed soil engineering indicators are determined by heavy-duty compaction tests.

[0084] Obtain the degree of compaction required in actual subgrade soil engineering.

[0085] According to the degree of compaction, the optimum water content and the maximum dry density, the mass and amount of water needed to prepare the molded sample are calculated; the air-dried soil is a soil sample that meets the roadbed soil engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com