Device for cleaning and drying piston parts

A drying device and parts technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as corrosion, physical injury, object surface cavitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

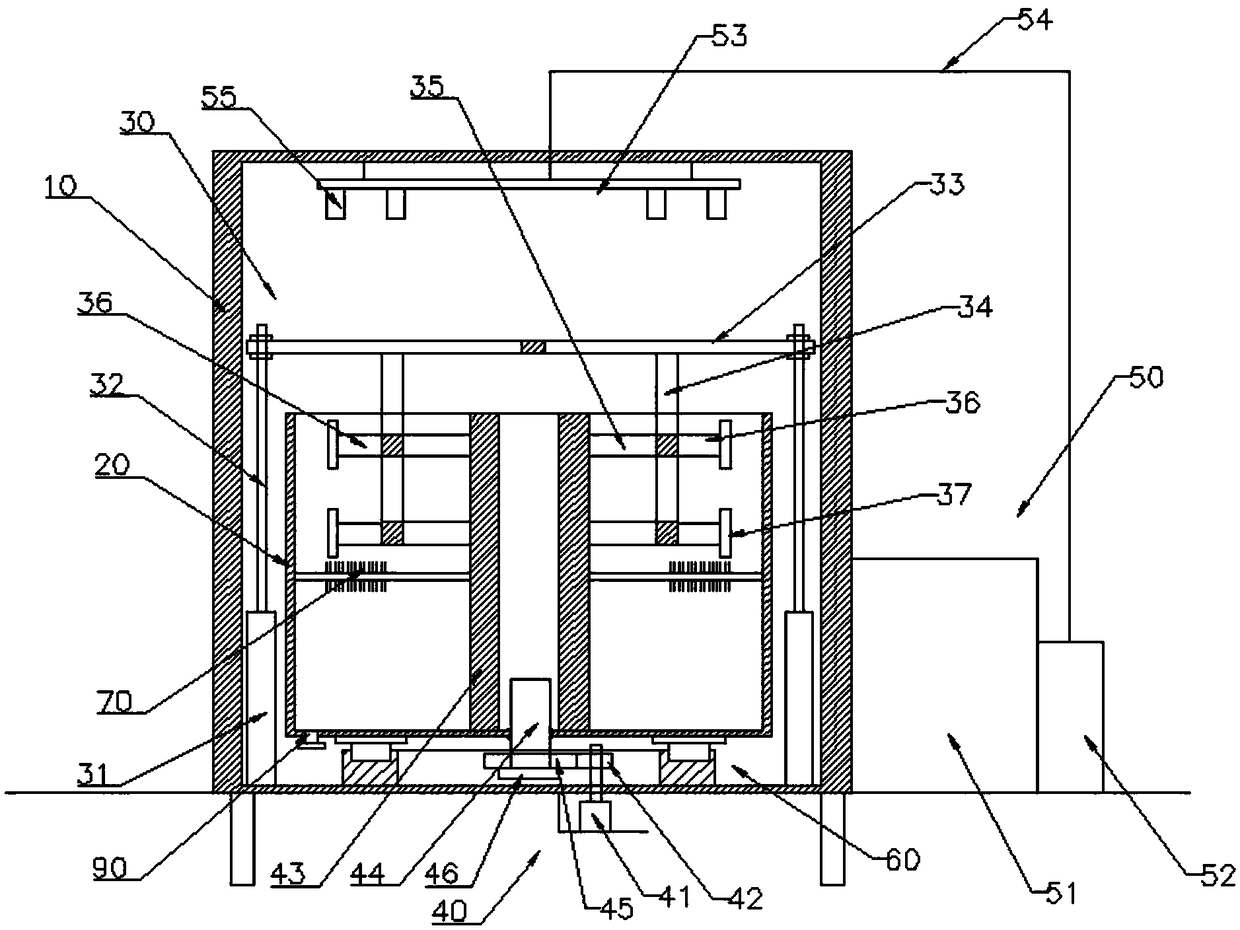

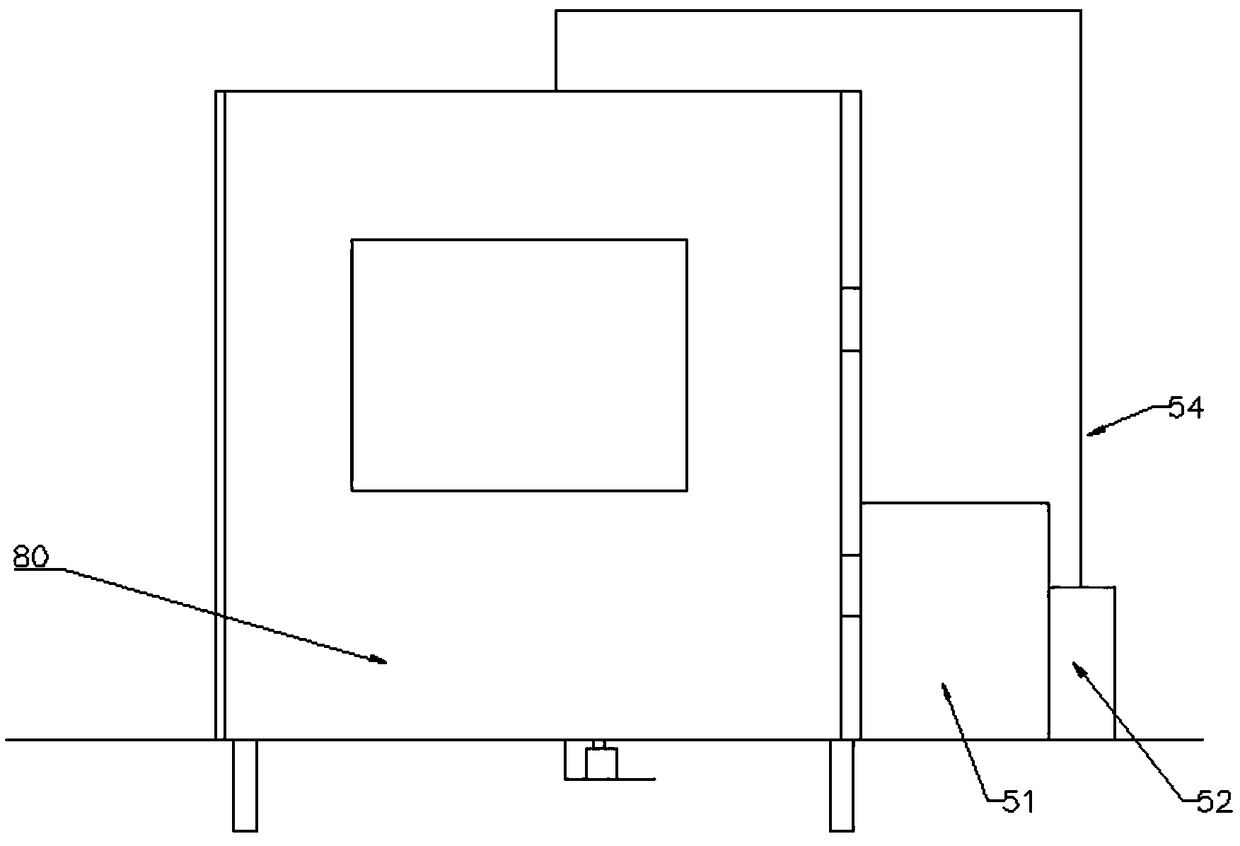

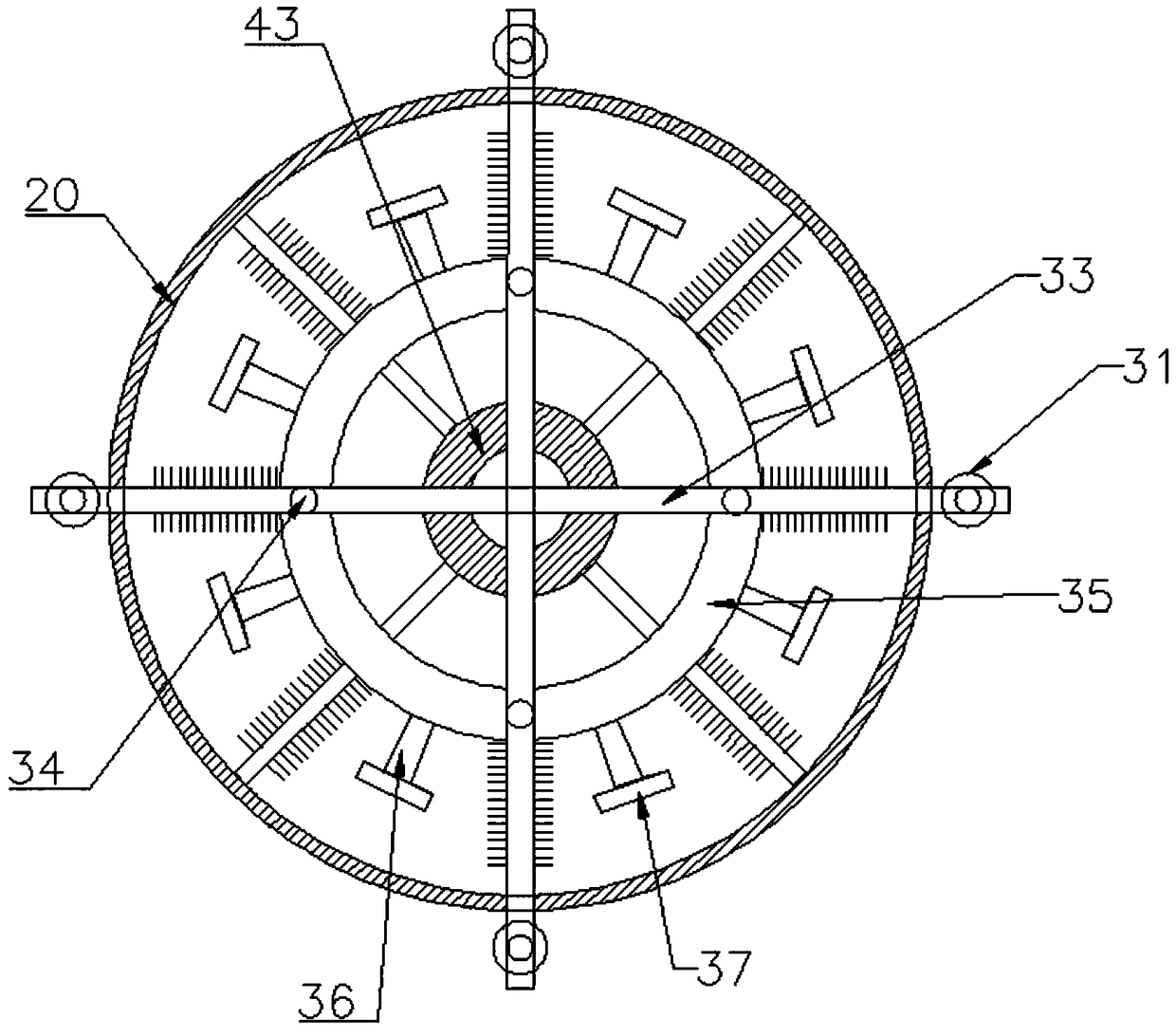

[0022] combine Figure 1 to Figure 4 The shown device for cleaning and drying piston parts, in this embodiment, includes an outer box 10, an inner box 20 located inside the outer box 10, and the inner box 20 and the outer box. The lifting device 30 between 10, the rotating device 40 arranged at the bottom of the inner box 20, and the drying device 50 arranged at the top of the outer box 10, the lifting device 30 includes four cylinders 31, The connecting rod 32 connected to the piston rod of the cylinder 31, the two supporting rods 33 connected to the connecting rod 32 and distributed in a cross shape, the four supporting rods 34 vertically connected to the bottom of the supporting rod 33, and the supporting rods 34 There are two sets of annular hangers 35, the side of the annular hanger 35 away from the shaft core is vertically connected with a number of hanging rods 36, and the end of the hanging rods 36 is connected with a blocking cover 37 by screws. The motor 41 at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com