Self-adaptive gas check for die pad on punching machine

An airtight device and self-adaptive technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve problems such as air bag leakage, minor faults and major repairs, and easy loosening of screws, etc., to achieve convenient installation, simple maintenance, and avoid The effect of loosening and shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

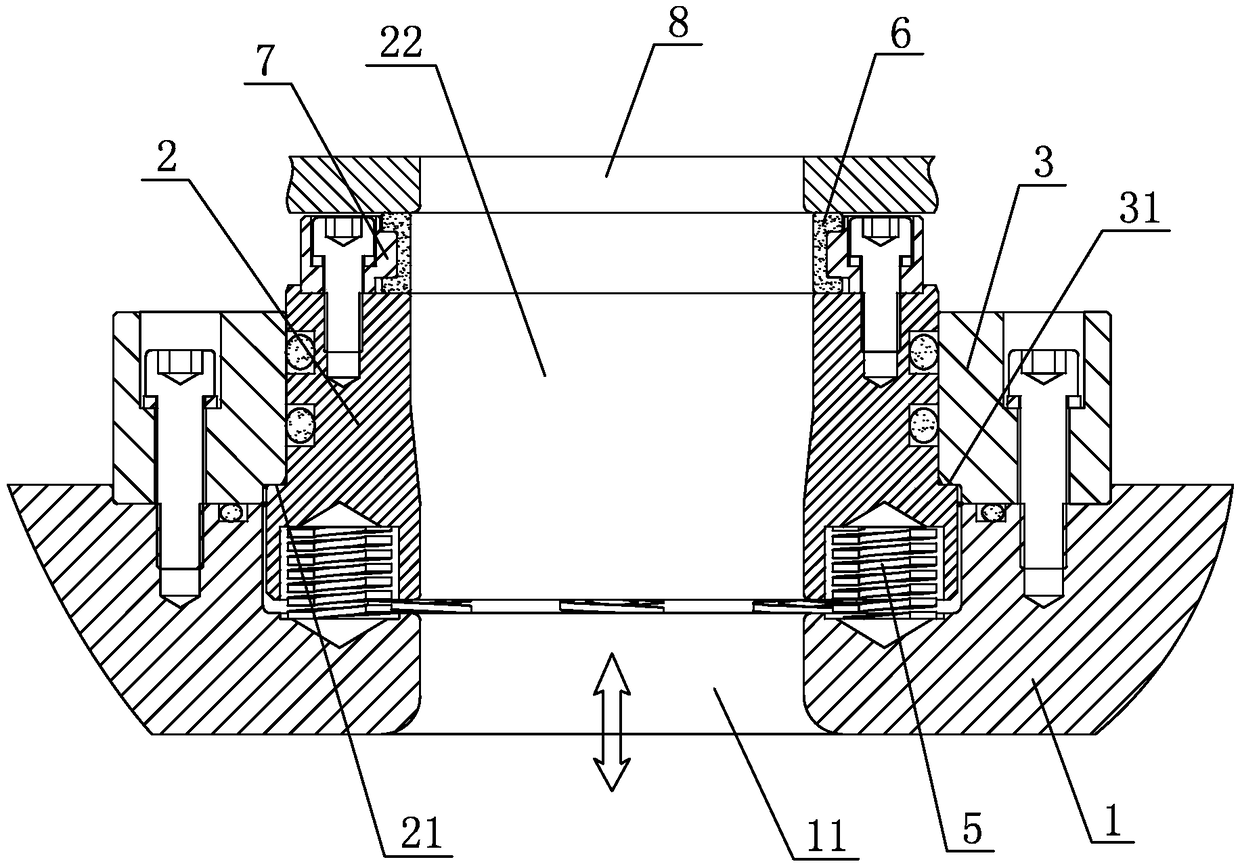

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

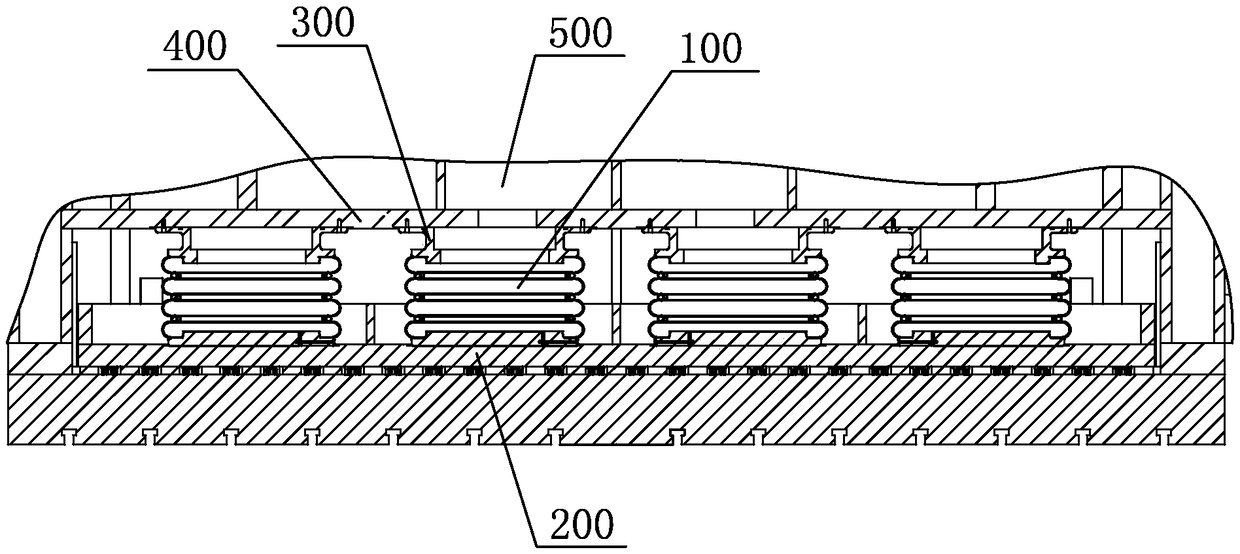

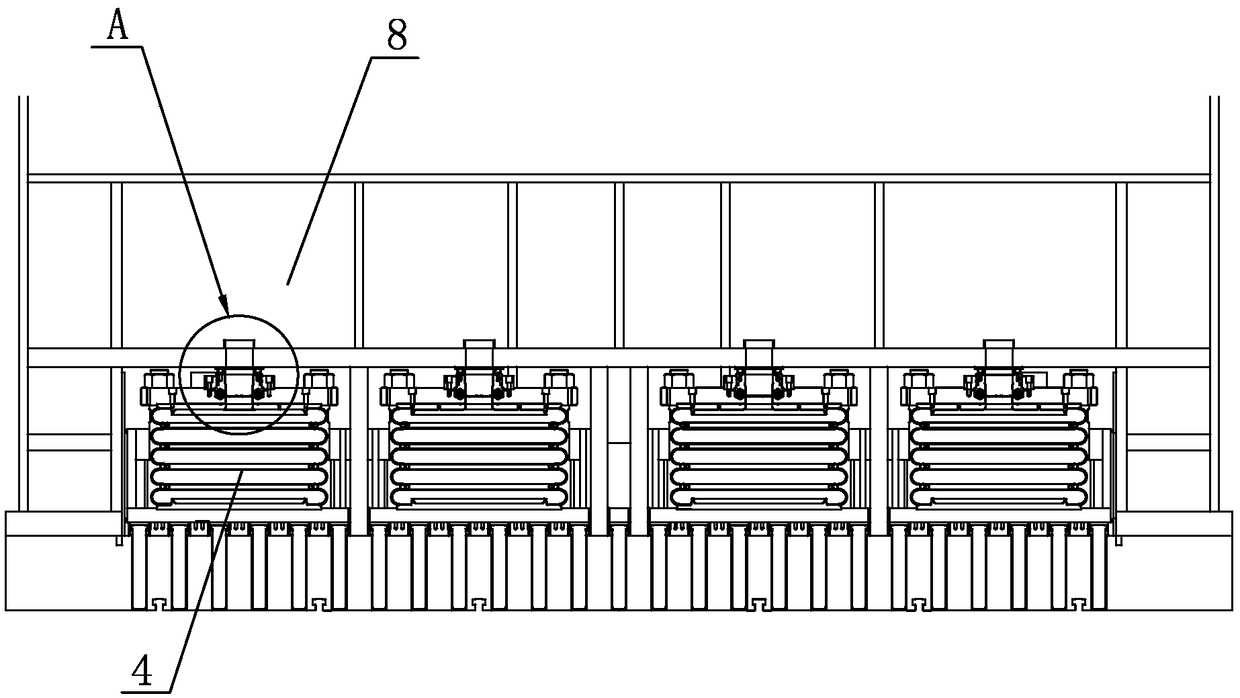

[0017] As shown in the figure, an adaptive airtight device for a die pad on a punching machine includes a fixed seat 1, a piston 2, a retaining ring 3 and a sealing ring 6, and the lower end of the fixed seat 1 is sealed and fixedly connected with the air bag or cylinder block 4, The fixed seat 1 is provided with a first air channel 11, the piston 2 is arranged in the fixed seat 1 and is in sealing and sliding fit with the fixed seat 1, the retaining ring 3 is set on the piston 2 and is fixedly connected with the fixed seat 1, the inner part of the retaining ring 3 The surface is integrally provided with a first positioning step 31, and the outer surface of the piston 2 is integrally provided with a second positioning step 21. The first positioning step 31 is offset against the second positioning step 21 to prevent the piston 2 from slipping ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com