PVC pipe bundling and film laminating device

A technology of PVC pipe and film covering device, which is applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of packaging bag damage, low efficiency, and affecting appearance, and achieve high automation, improve production efficiency, and reduce The effect of human involvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

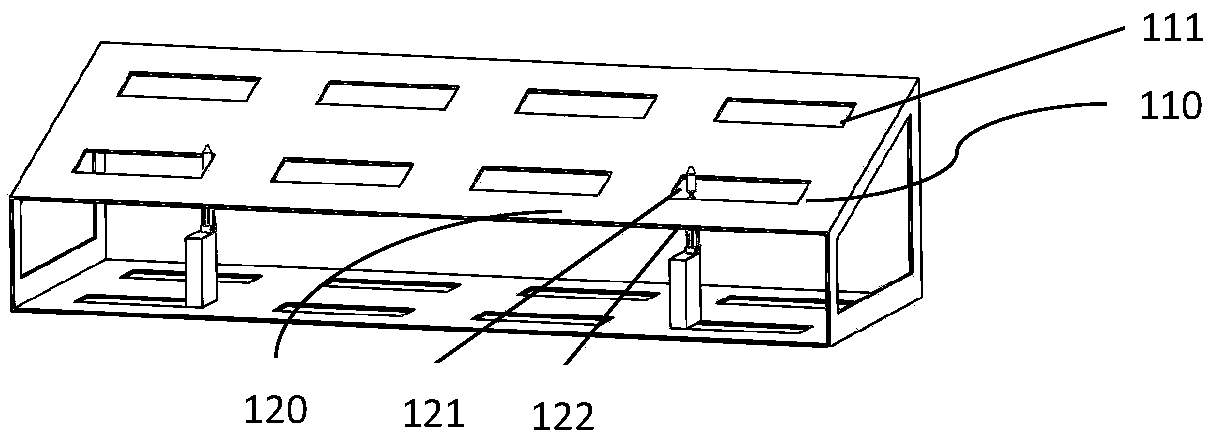

[0028] The packaging specifications of the PVC pipes selected in this embodiment are 3 lines, the number of each line is 3, 4, and 3 successively, and the number of a single PVC pipe group is 10, and the number of PVC pipe groups is not subject to the above-mentioned quantity. limit.

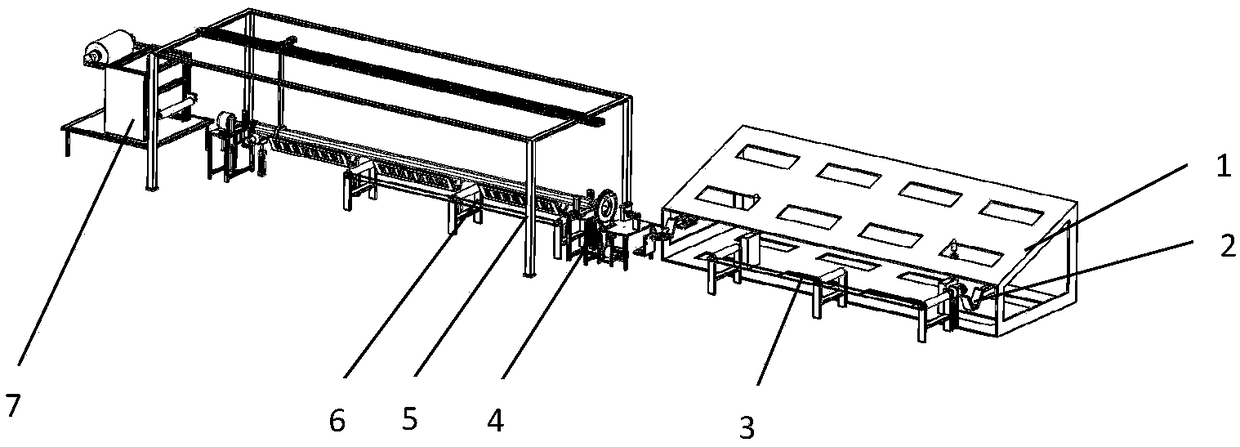

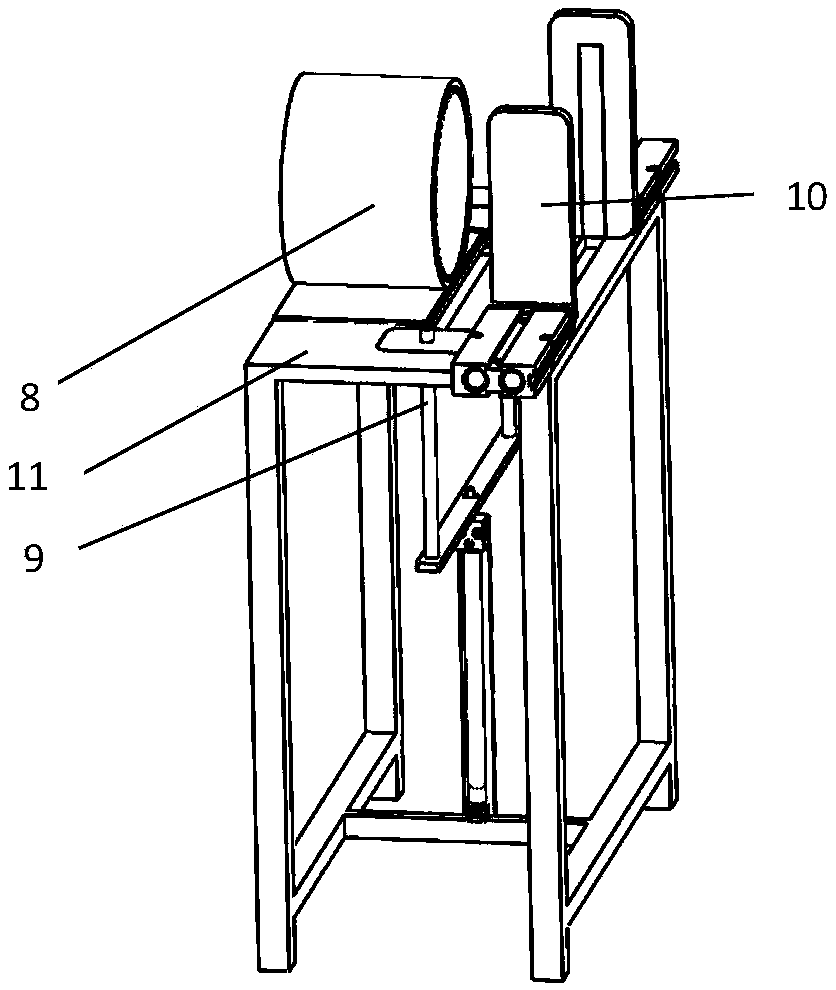

[0029] like figure 1 , figure 2 As shown, a PVC pipe bundling and film covering device includes a material feeding mechanism 1, a PVC pipe group alignment mechanism 2, a winding machine 4 and a film covering mechanism 5, and the PVC pipe group alignment mechanism 2 is arranged on one side of the material feeding mechanism 1. Side, after the PVC pipe is extruded by the extrusion equipment, the PVC pipe moves to the first conveying line 3 along with the incoming material mechanism 1, the first conveying line 3, the winding machine 4, the second conveying line 6 and the film feeder 7 Set in a straight line in turn, the PVC pipe group alignment mechanism 2 is arranged directly above the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com