Damping base of mining machine

A technology for mechanical shock absorption and mining, which is applied in shock absorbers, mechanical equipment, springs/shock absorbers, etc. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

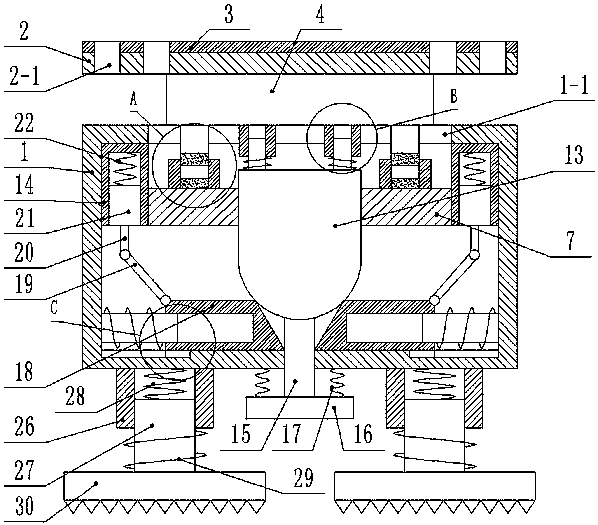

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

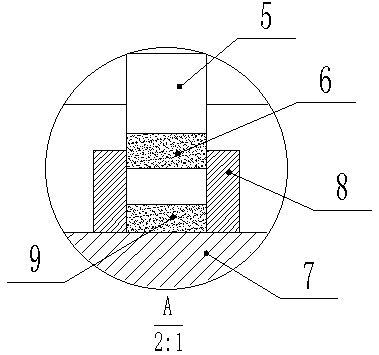

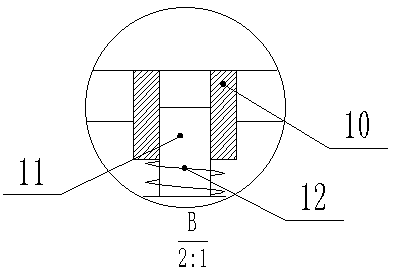

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a mining machinery shock-absorbing base includes a housing 1, a horizontal plate A2 is arranged above the housing 1, an anti-skid layer 3 is fixed on the upper end of the horizontal plate A2, and bolt holes are provided on the horizontal plate A2 2-1, the bolt holes 2-1 pass through the anti-skid layer 3, the lower end of the horizontal plate A2 is fixed with a connecting plate 4, and the upper wall of the housing 1 is provided with a square through hole 1- that matches the connecting plate 4 1. The lower end of the connecting plate 4 is fixed with two vertical rods A5 and sleeves B10, the two sleeves B10 are respectively on both sides of the lower end of the connecting plate 4, and the two vertical rods A5 are in the middle of the two sleeves B10 , the lower end of the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com